1. Introduction

The Resistance Probe of EMT is specifically engineered to monitor hydrogen permeation in steels. This monitoring is vital as hydrogen atoms diffusing into steel can cause microscopic structural changes. Over time, these changes can lead to significant material degradation.

Importance

By accurately tracking hydrogen levels, the probe helps prevent severe steel degradation issues such as embrittlement, blistering, and decarburization. These conditions can weaken steel, making it brittle and less ductile, thereby increasing the risk of sudden material failures in critical applications.

Operating Conditions

The probe is robust, designed to function optimally in high-pressure environments reaching up to 26MPa. This capability is crucial for applications in sectors like oil and gas, where equipment often operates under extreme pressure conditions.

2. Materials and Durability

Product Specifications

- Brand Name: EMT Pigging

- Product Name: Resistance Probe

- Material: Stainless Steel 316, L DUPLEX SS

- Size: 3″ x 3/4″ x 1/16″

- Design Temperature: -20℃ to 200℃

- Design Pressure: 0 to 26MPa

- Keyword: High Pressure Hydrogen Probe

- Feature: High Accuracy, Low Cost

- Certification: ISO9001

Additional Technical Details

- Metal Material: Stainless Steel 316, L DUPLEX SS

- Sealing Material: Teflon/Fluororubber

- Access Fitting Body and Protective Cover:

- Flange Size: ANSI 2″ RF (or RJ)

- Material: CS, 316L, DUPLEX SS

Packaging and Delivery

- Selling Units: Single item

- Package Size: 10 x 4 x 2 cm

- Gross Weight: 1.000 kg

Payment and Warranty

- Payment Terms: TT/LC

- Warranty: 1.5 years

Customized Support

- Options: OEM, ODM services available to tailor the probe to specific industrial needs.

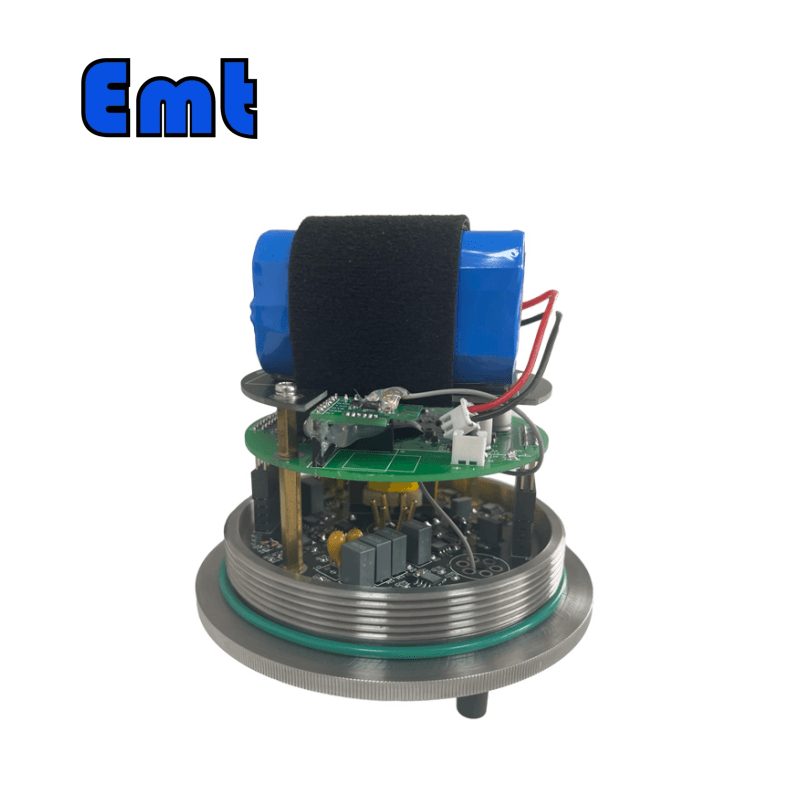

Core Materials

Constructed from high-grade Stainless Steel 316 and L DUPLEX SS, the probe offers exceptional mechanical strength and corrosion resistance. These materials are chosen for their ability to withstand harsh chemical environments and maintain structural integrity over long periods.

Advantages

The durability of these materials ensures the probe’s longevity and reliability in industrial settings. Their chemical resistance is particularly beneficial in corrosive environments, preventing the probe itself from becoming a liability in the systems it is meant to protect.

3. Installation and Configuration

Installation Options

The EMT-CP corrosion probe can be installed using two main methods: welding or flange mounting. This flexibility allows for easy integration into a variety of industrial systems, whether retrofitting existing equipment or installing new setups.

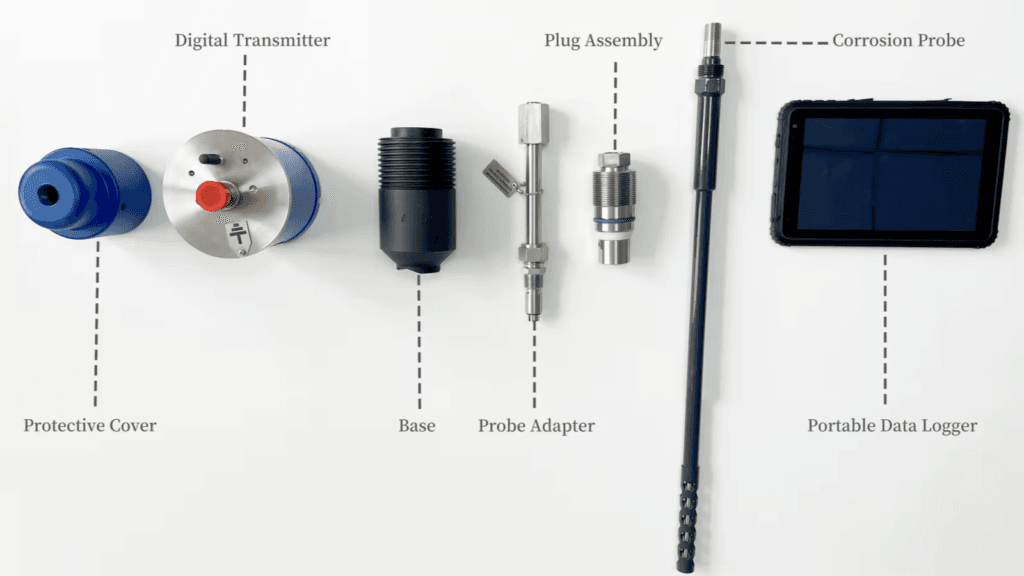

Components Included

Each probe assembly comes with a protective cover to shield sensitive components from environmental hazards, a hollow plug body that maintains the integrity of the installation point, and integrated temperature and pressure gauges. These gauges provide critical real-time data that is essential for maintaining operational safety and efficiency.

Flexibility

Designed to be adaptable, the probe fits seamlessly into various system configurations. This adaptability makes it an ideal choice for diverse industrial applications, ensuring that regardless of the system design, the probe can be installed without compromising its functionality or efficiency.

This detailed introduction highlights the Resistance Probe’s capabilities and its essential role in safeguarding industrial steel structures against hydrogen-induced damage, ensuring operational continuity and safety in high-stakes environments.

4. Features and Benefits

Easy Operating

The corrosion probe features a user-friendly design that simplifies the operation process, allowing for quick and efficient use. So this streamlined operation is facilitated by intuitive controls and easy access to the probe’s main functions, which means less time needed for training and more time focusing on critical testing and diagnostics.

High Accuracy and Longevity

This resistance probe is engineered to provide high-precision readings in various environmental conditions, ensuring reliable data for making informed decisions about pipeline integrity. The use of robust Stainless Steel 316 and L DUPLEX SS materials enhances the probe’s durability, allowing it to withstand harsh operational conditions such as extreme temperatures and high pressures, thus extending its operational life.

High Efficiency and Low Cost

Designed with cost-efficiency in mind, the EMT corrosion probe offers high-performance features without the premium price tag. This balance is achieved through smart design choices that optimize material use and manufacturing processes, ensuring that the probe not only performs well but also remains economically viable for widespread deployment in industrial settings.

Lightweight and Flexible

The physical design of the probe is both lightweight and flexible, making it easy to handle and install. This flexibility is particularly beneficial in complex pipeline systems where space and access may be limited. The lightweight nature of the probe reduces the strain on operators during installation and maintenance, thereby decreasing the risk of installation errors and improving overall safety.

Excellent Injection Efficiency

Because the resistance probe’s design optimizes the delivery of testing mediums, which is crucial for accurate corrosion testing. So this is achieved through a well-engineered injection system that ensures that the testing medium is distributed evenly and consistently across the test area. Such as efficiency is vital for obtaining reliable data and ensuring that the probe’s readings accurately reflect the condition of the pipeline.

Accurate Location Tracking

So accurate location tracking is essential for pinpointing areas of concern within the pipeline. The EMT resistance probe is equipped with advanced location tracking technology that provides precise monitoring and diagnostics. This capability is critical for targeted maintenance and repairs, helping pipeline operators to quickly and efficiently address potential issues before they escalate into costly failures.

There are no reviews yet.