1. Introduction:

The EMT Quill Chemical Injection, designed and manufactured by EMT Pigging, is a specialized device used primarily in the oil and gas industry, as well as in other sectors like mining and construction. This system is integral to maintaining pipeline integrity through the controlled injection of chemicals directly into the pipeline stream. These chemicals help in preventing corrosion, scaling, and fouling that can severely impact pipeline operations.

2. Product Specifications:

- Type: Injection & Sampling System

- Brand: EMT Pigging

- Condition: New

- Product Name: Chemical Injection Quill

- Sealing Material: Fluororubber

- Working Temperature: -20 to 200°C

- Working Pressure Options:

- 150LB

- 300LB

- 600LB

- 900LB

- 1500LB

- Solid Plug Assembly Material: 316L Stainless Steel

- Injection Tube Material: 316L Stainless Steel

- NPT Nozzle Material: 316L Stainless Steel

- Flange Material: ASTM A105N

- Application: Pipeline Testing

- Certification: ISO 9001

- Warranty: 1.5 years

- Place of Origin: Liaoning, China

3. Key Features:

- Weight: 5 kg

- Packaging Dimensions: 35 x 40 x 60 cm

- Gross Weight of Package: 8 kg

- Showroom Location: None

- Video Outgoing-Inspection: Provided

- Machinery Test Report: Provided

4. Applicable Industries:

- Building Material Shops

- Construction Works

- Energy & Mining

- Pipeline Pigging

- Oil & Gas Pipeline

5. Operation and Maintenance:

- Usage: The Chemical Injection Quill is designed for periodic injection of chemical inhibitors into pipelines to control or minimize corrosion efficiently. This system allows for the injection of chemicals under operating pressure safely and reliably.

- Mounting Types:

- 2″ Flange

- 2″ Flareweld Access Fitting

- 1″ Nipple to NPT Ball Valve

- Pressure Rating: Up to 6000 PSI or as per Flange Size

- Temperature Range: -20 °C to 150 °C

Name | Chemical Injector Quill | |

| Material | Stainless Steel 304, Stainless Steel 316, DSS F51, Carbon Steel A105N, and also Inconel 625 | |

| Operating Temperature | -20±120 | |

| Feature | Firstly, easy Operating | |

| Secondly, high Accuracy Long Life | ||

| At last, high Efficiency, Low cost | ||

| Payment | TT/LC | |

| Advantage | Firstly, they are lightweight and flexible. | |

| Secondly, excellent Injection efficiency. | ||

| At last, accurate location tracking. |

| Model | ||||||||||||||||||||||||||||

SI | Chemical Injector Quill | |||||||||||||||||||||||||||

| -Code | Plug | |||||||||||||||||||||||||||

| Pxxx | Type | Material | Sealing Material | |||||||||||||||||||||||||

| 0 | No Request | 0 | CS | 0 | No Request | |||||||||||||||||||||||

| 1 | Hollow Plug Body | 1 | 316SS | 3 | DSS | 1 | Viton O-Ring / PTFE Primary Packing | |||||||||||||||||||||

| 2 | Solid Plug Body | 2 | 316LSS | 4 | INCONEL | 2 | HNBR | |||||||||||||||||||||

| – Code | Injection Nut | |||||||||||||||||||||||||||

| Nxx | Connection Size | Material | ||||||||||||||||||||||||||

| 0 | i.e. No Request | 0 | i.e. CS | |||||||||||||||||||||||||

| 1 | i.e. 1/4″ | 1 | i.e. 316SS | 3 | i.e. DSS | |||||||||||||||||||||||

| 2 | i.e. 1/2″ | 2 | i.e. 316LSS | 4 | i.e. INCONEL | |||||||||||||||||||||||

| – Code | Injection Tube | |||||||||||||||||||||||||||

| Sxxx-Lx″ | Connection Size | Material | Nozzle | Line size(x″) | ||||||||||||||||||||||||

| 0 | No Request | 0 | CS | 0 | i.e. No Request | The most effective position for injection is generally at the center of the pipe | ||||||||||||||||||||||

| 1 | i.e. 1/4″ | 1 | i.e. 316SS | 1 | i.e. Open | |||||||||||||||||||||||

| 2 | i.e. 1/2″ | 2 | i.e. 316LSS | 2 | i.e. Quill | |||||||||||||||||||||||

| 3 | i.e. DSS | 3 | i.e. Cap & Core | |||||||||||||||||||||||||

| 4 | i.e. INCONEL | |||||||||||||||||||||||||||

| – Code | Nipple and Valve(or end Flange)of Tee | |||||||||||||||||||||||||||

| Txx | Connection Size | Material | ||||||||||||||||||||||||||

| 0 | i.e. No Request | 0 | i.e. CS | |||||||||||||||||||||||||

| 1 | i.e. 1/4″Nipple | a | i.e. 1/4″Nipple and Valve | 1 | i.e. 316SS | |||||||||||||||||||||||

| 2 | i.e. 1/2″Nipple | b | i.e. 1/2″Nipple and Valve | 2 | i.e. 316LSS | |||||||||||||||||||||||

| 3 | i.e. 3/4″Nipple | c | i.e. 3/4″Nipple and Valve | 3 | i.e. D SS | |||||||||||||||||||||||

| 4 | i.e. 1″Nipple | d | i.e. 1″Nipple and Valve | 4 | i.e. INCONEL | |||||||||||||||||||||||

| 5 | i.e. 1/4″Flange | e | i.e. 1/4″Nipple end Flange | |||||||||||||||||||||||||

| 6 | i.e. 1/2″Flange | f | i.e. 1/2″Nipple end Flange | |||||||||||||||||||||||||

| 7 | i.e. 3/4″Flange | g | i.e. 3/4″Nipple end Flange | |||||||||||||||||||||||||

| 8 | i.e. 1″Flange | h | i.e. 1″Nipple end Flange | |||||||||||||||||||||||||

6. Detailed Specifications and Features

Material Construction:

- Solid Plug, Injection Tube, and NPT Nozzle: All critical components are made from 316L stainless steel, known for its superior corrosion resistance and durability in harsh chemical environments.

- Flange: Manufactured from ASTM A105N, ensuring robust performance under varying pressure conditions and compatibility with existing pipeline materials.

Operational Parameters:

- Temperature and Pressure Ranges: Designed to operate effectively within a temperature range of -20°C to 200°C and available in multiple pressure ratings (150LB to 1500LB). This versatility allows it to be adapted to different operational demands and pipeline specifications.

- Sealing Material: Utilizes fluororubber for its seals, which provides excellent resistance to high temperatures and aggressive chemicals, ensuring that the integrity of the seal is maintained even under extreme conditions.

7. Advanced Design and Functionality

Chemical Injection Process:

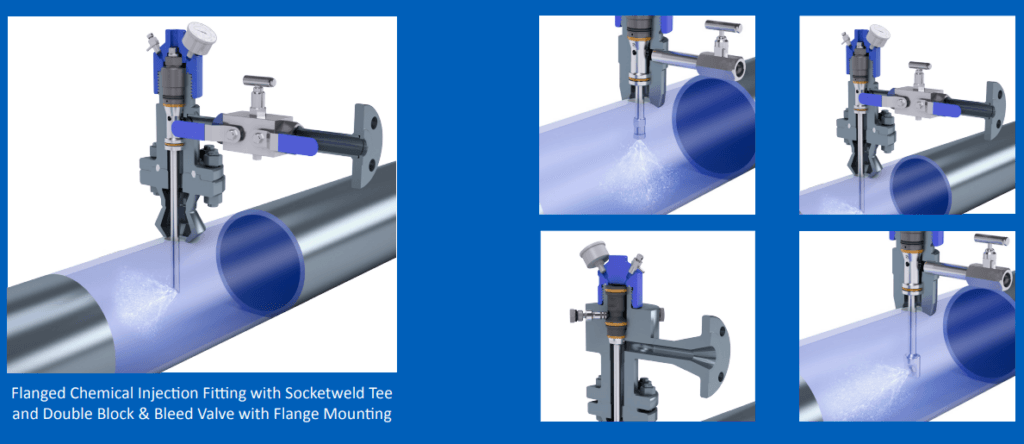

- The quill injects chemicals at a point deep within the pipeline, which ensures a thorough mixing with the transported medium. This deep insertion minimizes the degradation of pipeline walls and fittings that could be caused by direct contact with harsh chemicals.

Safety and Reliability:

- The design of the EMT Chemical Injection Quill includes features that allow for safe injection under full operating pressure, without the need for shutdowns or disruptions in pipeline flow. This is critical for maintaining continuous operations in industries where downtime can be incredibly costly.

Ease of Installation and Maintenance:

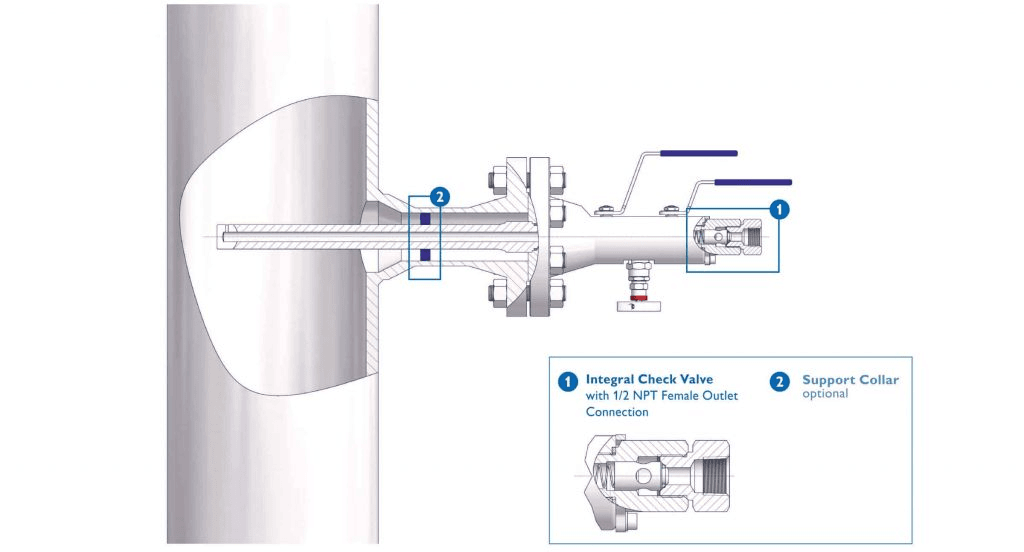

- The quill can be mounted directly to the pipeline through various methods such as flanged connections, flareweld access fittings, or threaded connections via a nipple to NPT ball valve. This flexibility in mounting options facilitates easy installation and maintenance.

- The system’s design also allows for easy access to replace or service the injection nozzles and check valves, ensuring long-term reliability and performance.

8. Certification and Quality Assurance

ISO 9001 Certified:

- The EMT Chemical Injection Quill is manufactured in an ISO 9001 certified facility, guaranteeing adherence to international quality management standards. This certification underscores the company’s commitment to producing high-quality, reliable products.

Inspection and Testing:

- Each unit undergoes rigorous testing and inspection before shipment. This includes video outgoing inspections and machinery test reports provided to the customer, ensuring that each system meets the stringent operational criteria set forth by both the industry and regulatory bodies.

There are no reviews yet.