Quick Opening Closure Vertical (QOCs) are mechanical devices used on circular openings of pressure vessels and pipelines. They are designed to facilitate rapid and safe access for inspection, cleaning, and maintenance operations, commonly found in the natural gas industry and other sectors involving frequent opening and closing of pressurized equipment.

1. Technical Specifications

- Nominal Diameter (Dn): Up to 1600 mm

- Design Pressure (Pn): Up to 40 MPa

- Working Mediums: Oil, gas, and water

- Design Temperature Range: -50°C to 300°C

- Material: Carbon steel

- Pipe Thickness: Ranging from 6 mm to 100 mm

Design Pressure | 1.6MPa-30MPa | |||

Corrsoion Allowance | 2mm | |||

Seismic Fortification Intensity | 7 Degrees | |||

Work Medium | Oil,Nature gas,Water and ore pulp etc. | |||

Opening Time | Within 60s less than 200N | |||

Opening Type | Vertical or Horizontal | |||

2. Components and Design

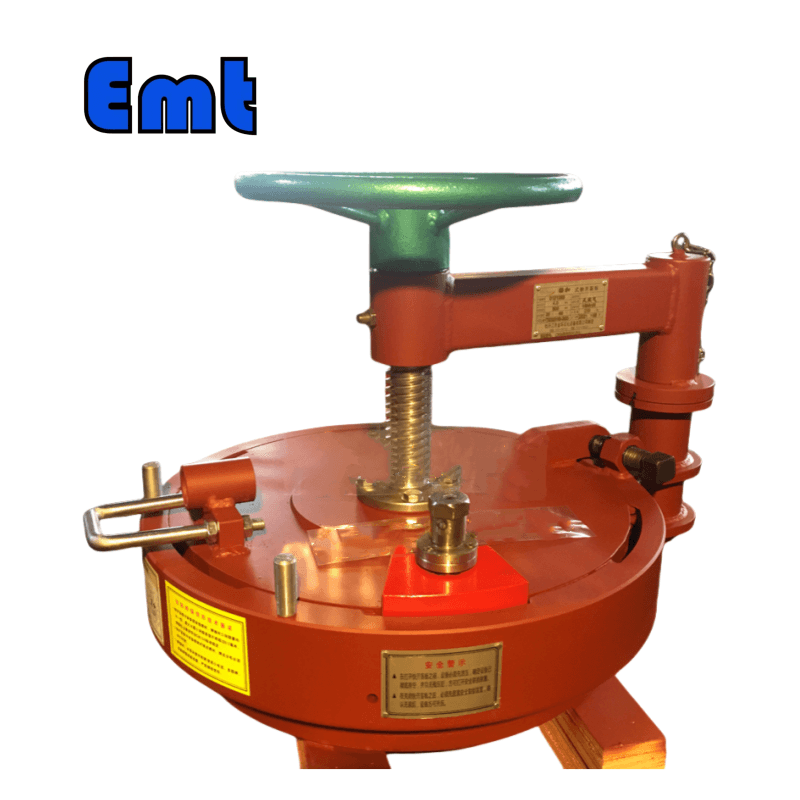

A typical Quick Opening Closure Vertical consists of several key components:

- Body Flange. Connects the closure to the pipeline or vessel.

- Cover. Seals the opening when closed.

- Latch or Clamp. Secures the cover in place and ensures we can quickly release it.

- Sealing Ring. Provides a tight seal to prevent leaks.

- Safety Interlock Mechanism. Prevents accidental opening under pressure.

- Opening Mechanism. Facilitates the manual opening of the closure.

These closures come in various types, including thread engagement, clamp, bayonet, locking ring, expansion ring, and fixed pressure ring, primarily operated manually.

3. Types of Quick Opening Closures

Clamp

Clamp closures feature a simple and effective design where a clamping mechanism is to secure the lid to the body. These are quick to open and close, requiring minimal effort and tools. Clamp closures are favored in applications where frequent access is needed, as they can be operated rapidly and effortlessly.

Bayonet

Bayonet closures incorporate a twist-and-lock mechanism, similar to a bayonet light bulb. This design allows for quick and secure locking by aligning pins on the closure with corresponding slots or grooves on the vessel and twisting to lock. Bayonet closures are known for their quick operation and are commonly used in applications requiring frequent, easy access.

Locking Ring

Locking ring closures use a segmented ring that tightens around the circumference of the closure to lock it into place. This type is particularly effective for ensuring a tight seal and is often in environments where safety and leakage prevention are paramount. The locking ring mechanism is robust, providing a high level of security and pressure tolerance.

4. Manufacturing and Standards

Our company designs Quick Opening Closures in accordance with ASME VIII Div.1 and undergo rigorous Finite Element Analysis (FEA) to ensure structural integrity under pressure. They are crafted from integral forgings of low-alloy, high-strength carbon steel, which provides excellent durability and resistance to harsh operational conditions.

The closures fully comply with GB150 national regulations and adhere to the SY/T0556-2018 industry standard, which specifies technical requirements for quick-change blind plates.

5. Applications

Quick Opening Closures (QOCs) are integral components in the oil and natural gas industries, providing critical functionality in several key operations:

Pig Launchers and Receivers

Quick Opening Closures are vital in pigging operations, which works to clean and inspect pipelines. Known as pig traps, these devices facilitate the insertion and retrieval of pipeline inspection gauges, commonly called “pigs.” The quick opening feature allows for fast and efficient changes between operations, reducing downtime and ensuring pipeline integrity and flow efficiency. These systems are crucial for maintaining pipelines in optimal condition, preventing corrosion and buildup that can lead to blockages and decreased efficiency.

Filters and Filter Separators

In the processing of oil and natural gas, removing impurities and separating components are fundamental processes. Quick Opening Closures are employed on filter and separator units, enabling quick access for maintenance and inspection. These closures ensure that filters can be promptly cleaned or replaced, thereby maintaining continuous operation and effectiveness. The quick access significantly cuts down on the time required for routine maintenance and unexpected repairs, enhancing overall operational efficiency.

Booster Vessels and Vulcanizing Tanks

Quick Opening Closures are also used in booster vessels and vulcanizing tanks, which are pressure vessels used in various processing applications. Including the enhancement of product flow and the curing of materials. The ability to quickly and safely open these vessels is crucial, especially under high-pressure conditions. The closures allow for rapid pressure equalization and safe access, which is essential for operational safety and productivity.

Pressure Vessels with Quick-Access Doors

In many industrial applications, Quick Opening Closures equip on the pressure vessels to facilitate frequent access for inspection, cleaning, and maintenance. These quick-access doors are designed to withstand the operational pressures and temperatures typical in industrial environments while providing a safe and efficient means of access. Whether for chemical reactors, autoclaves, or other specialized vessels, these closures support stringent safety standards and regulatory compliance.

1.Many kinds of quick opening closure with different type to meet difference requirements.

2. The fastest feedback!

3. The fastest delivery time.

4.24 hours,7 days online.

There are no reviews yet.