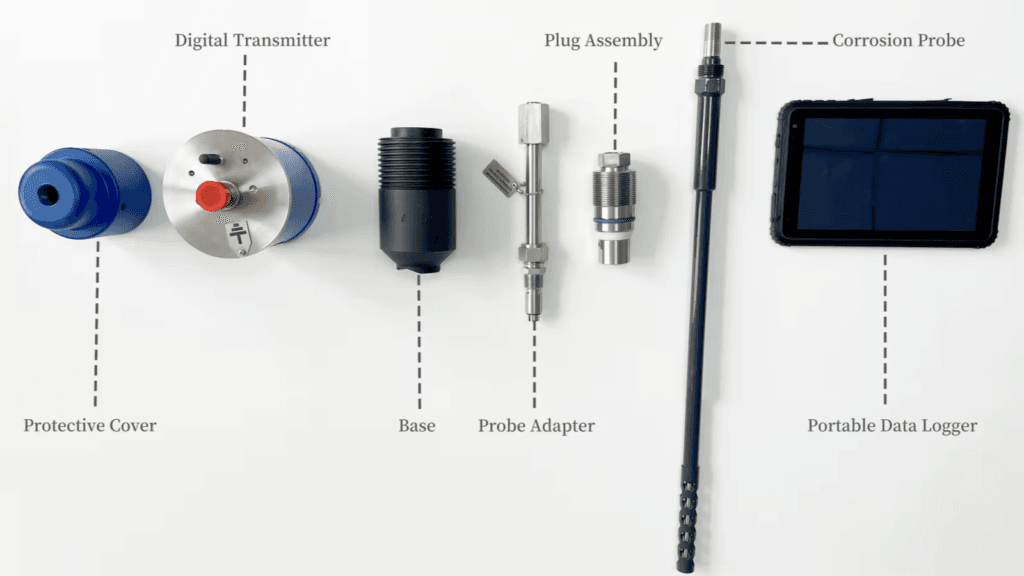

1. EMT-CP Corrosion Probe

The EMT-CP Corrosion Probe is specifically engineered for monitoring hydrogen permeation in steels. This is crucial in industries where steel structures or components are exposed to hydrogen under high pressure, as hydrogen can cause serious material degradation through embrittlement, blistering, and decarburization. These phenomena can lead to catastrophic failures, making accurate and early detection essential.

- Metal Material : 316、L DUPLEX SS

- Sealing Material : Teflon/ Fluororubber

- Working Temperature : -20~200℃

- Working Pressure : 0~26MPa

- Access Fitting Body and Protective Cover :

- Size of Flange : ANSI 2″ RF (or RJ)

- Material : CS 、316L、 DUPLEX SS

- Working Pressure : 0~26MPa

- Working Temperature : -20~200℃

2. Construction and Material Details

Selection Model

| Model | |||||||||||||||

| ECP | EMT-CP Corrosion Probe | ||||||||||||||

| -Code | Plug | ||||||||||||||

|

Pxxx | Type | Material | Sealing material | ||||||||||||

| 0 | Not Required | 0 | Carbon steel | 0 | Not Required | ||||||||||

| 1 | Hollow plug | 1 | 316 stainless steel | 1 | Fluorine rubber sealing ring/PTFE main seal | ||||||||||

| 2 | 316L stainless steel | 2 | HNBR | ||||||||||||

| 3 | F51 duplex stainless steel | ||||||||||||||

| 4 | INCONEL nickel based alloy | ||||||||||||||

| -Code | Temperature and pressure gauge assembly | ||||||||||||||

| Txxx | Connection size | Body material | Temperature and pressure gauge material | ||||||||||||

| 0 | Not Required | 0 | 304 stainless steel | 0 | Not Required | ||||||||||

| 1 | 1/2″ | 1 | 316 stainless steel | 1 | 304 stainless steel | ||||||||||

| 2 | 3/4″ | 2 | 316L stainless steel | 2 | 316 stainless steel | ||||||||||

| 3 | F51 duplex stainless steel | ||||||||||||||

| -Code | Probe assembly | ||||||||||||||

| Dxx ‐Lx″ | Connection size | Body material | Pipeline specification (x ″) | ||||||||||||

| 0 | Not Required | 0 | Carbon steel | Probe length varies with pipeline specifications | |||||||||||

| 1 | 1/4″ | 1 | 304 stainless steel | ||||||||||||

| 2 | 1/2″ | 2 | 304L stainless steel | ||||||||||||

| 3 | 316 stainless steel | ||||||||||||||

| 4 | 316L stainless steel | ||||||||||||||

| 5 | F51 duplex stainless steel | ||||||||||||||

Metal Materials

- 316 Stainless Steel and Duplex Stainless Steel (DUPLEX SS):

These materials are chosen for their excellent corrosion resistance and strength properties. It makes them ideal for use in harsh chemical and high-pressure environments. Stainless steel 316 provides excellent resistance against a variety of corrosive environments. Which is crucial for maintaining the integrity of the probe under extreme conditions.

Sealing Materials

- Teflon and Fluororubber: These materials work for seals within the probe assembly. Teflon is known for its chemical inertness and ability to withstand high temperatures, while fluororubber offers excellent resistance to heat and chemicals, ensuring a robust seal even under fluctuating temperature and pressure conditions.

3. Features and Specifications

Access Fitting Body and Protective Cover

- Materials: Carbon Steel (CS), 316L, and DUPLEX SS work for the access fitting body and protective cover, providing a harmonious balance of corrosion resistance and structural integrity.

- Flange Size: ANSI 2″ RF (or RJ), tailored to industry standards for easy integration into existing systems.

- Working Conditions: Capable of operating in temperatures ranging from -20°C to 200°C and pressures up to 26 MPa, matching the robustness required for high-pressure systems.

Operational Features

- Easy Operating: The Corrosion Probe is for simplicity and ease of use, so allowing for quick installation and minimal operational training.

- High Accuracy and Long Life: Precision in measurements ensures reliable monitoring of corrosion rates. And high-quality materials also extend the lifespan of the probe under harsh conditions.

- High Efficiency and Low Cost: Optimized for cost-effectiveness, the probe provides accurate data without the need for frequent replacements or maintenance.

4. Advantages of EMT-CP Corrosion Probe

a. Lightweight and Flexible

The EMT-CP Corrosion Probe is engineered using advanced materials that provide the necessary strength and durability while keeping the overall weight low. This lightweight nature offers several practical benefits:

- Ease of Handling: The reduced weight of the probe makes it easier for technicians to handle and manipulate during both installation and maintenance procedures.

- Flexible Installation: Flexibility in design means that the probe can be adapted to various mounting configurations, whether in horizontal or vertical alignments, without compromising its structural integrity or performance.

- Reduced Structural Load: The lightweight construction minimizes the load on existing pipeline systems or structures where installing this probe. Which is critical in minimizing stress and potential strain-induced damages.

b. Excellent Injection Efficiency

The probe’s design is optimized not only just for durability. But also for maximal efficiency in the injection and detection of hydrogen permeation. This is several design features:

- Optimal Contact with Medium: Firstly, the probe features a specialized tip geometry that ensures it makes comprehensive contact with the steel medium being monitored. This design maximizes the surface area exposed to hydrogen, enhancing detection capabilities.

- Enhanced Sensitivity: Then, by optimizing the way hydrogen interacts with the sensor elements within the probe, the system can detect even minimal changes in hydrogen levels. Which are crucial for early detection of potential issues.

- Uniform Dispersion: At last, the probe ensures uniform dispersion of hydrogen across the sensor surface, which is vital for accurate readings and helps in maintaining consistent monitoring across the monitored section.

c. Accurate Location Tracking

Precision engineering is at the heart of the EMT-CP Corrosion Probe’s design, focusing on accurate placement and data collection:

- Targeted Monitoring: By placing the probe at strategic points, it provides data that is critical for assessing the health of the system specifically at its weakest points, rather than general areas, ensuring more effective monitoring and maintenance planning.

- Customizable Configuration: At last, Depending on the specific needs and the layout of the installation site, the probe can be configured to target specific locations, accommodating bends, joints, and other complex configurations in piping and structural systems.

There are no reviews yet.