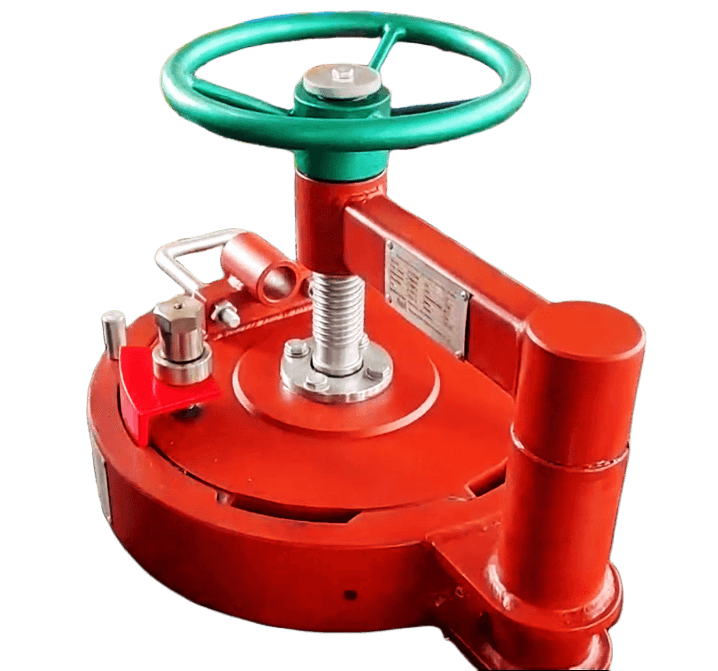

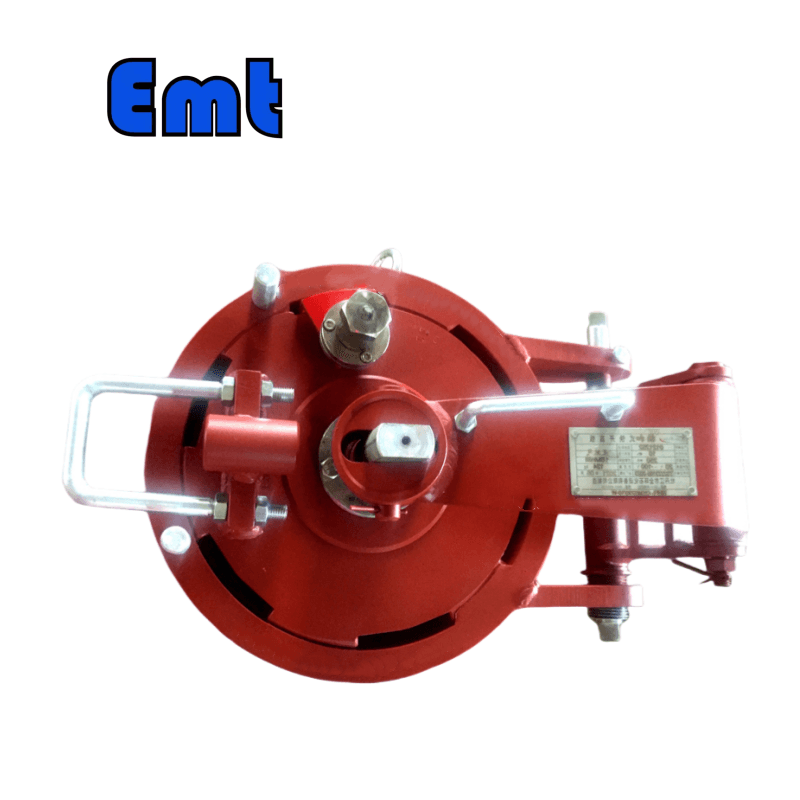

Pressure vessel closure is critical components in the construction and operation of pressure vessels used across various industries. These closures ensure the safe containment of gases or liquids at high pressures, vastly influencing the overall efficiency and safety of industrial operations.

1. Main Features:

- Installation Options. Provides flexibility for both vertical and horizontal installations.

- Size and Pressure Compatibility. Closures are available in a broad range of sizes and pressure ratings.

- Material Strength. Constructed from materials capable of withstanding extreme internal pressures and environmental conditions.

- Sealing Capabilities. High-quality seals prevent leaks and ensure the integrity of the vessel under pressure.

2. Adaptable Installation Options

Pressure vessel closure is designed to be versatile, accommodating both vertical and horizontal installations. This adaptability allows them to be integrated into various industrial setups with differing spatial constraints.

Benefits:

- Flexibility in Design. Whether the system design requires a vertical or horizontal vessel, these closures can be incorporated without significant modifications, simplifying the engineering process.

- System Integration. Adaptable installation options facilitate smoother integration with existing pipelines and infrastructure, reducing the need for additional space or extensive modifications.

- Space Utilization. The ability to choose the orientation of the vessel helps in optimizing space, especially critical in facilities where space is at a premium.

3. Wide Range of Sizes and Pressure Compatibility

Pressure vessel closure is available in a variety of sizes, typically ranging from DN 150 to DN 1800, making them suitable for a wide array of industrial applications. The sizing flexibility ensures that they can also be used in everything from small-scale operations to large infrastructure projects.

Pressure Ratings:

Pressure vessel closure can handle pressures up to ASME #1500. So this high-pressure capability makes them ideal for use in industries that operate under extreme pressure conditions.

Relevance Across Industries:

- Municipal Systems. Large diameter closures can be used in municipal water treatment plants for securing large filtration units or pressure vessels used in water purification.

- Oil and Gas Processing. The oil and gas industry benefits from high-pressure closures in applications like reactors and separators where maintaining the integrity of the system under high pressure is crucial.

- Chemical Manufacturing. Chemical reactors often require robust closures that can withstand the corrosive environment and high pressures, ensuring safe containment of reactive chemicals.

4. High-Strength Materials and Durability

Pressure vessel closure is constructed from high-strength materials such as SA 350 LF2 and various stainless steel variants. Then these materials are selected for their exceptional durability and ability to withstand harsh operational environments.

Materials Used:

- SA 350 LF2. This is a low-carbon, low-alloy steel known for its toughness and excellent notch toughness at low temperatures. It is commonly used in flange applications due to its strength and resilience.

- Stainless Steel Variants. Different grades of stainless steel are used depending on the specific resistance needed against corrosion and temperature. Stainless steels are essential for applications where corrosion is a significant concern, such as in marine or acidic environments.

Benefits of Material Choices:

- Durability. These materials offer high strength and resistance to mechanical stresses and impacts, prolonging the service life of pressure vessel closures.

- Resistance to Environmental Challenges. Stainless steel variants provide excellent corrosion resistance, crucial in preventing degradation in corrosive environments. So SA 350 LF2’s low-temperature resilience makes it ideal for cold climates where other materials might become brittle.

- Reduced Maintenance Needs. The robust nature of these materials minimizes the frequency and necessity for maintenance, reducing downtime and operational costs over the lifespan of the vessel.

5. Superior Sealing with Viton™ Seals

Viton™ seals are known for their high performance in extreme conditions, providing excellent heat and chemical resistance, which is crucial for maintaining system integrity and safety.

Properties of Viton™ Seals:

- Chemical Resistance. Viton™ is resistant to oils, fuels, lubricants, and most mineral acids, providing reliable sealing in chemical processing environments.

- High-Temperature Tolerance. These seals can withstand temperatures significantly higher than many other elastomers, making them suitable for high-temperature processes.

Benefits of Viton™ Seals:

- Enhanced System Integrity. The robust sealing capabilities ensure that the internal contents of pressure vessels are maintained without leakage, preserving system integrity.

- Leak-Proof Performance. The effectiveness of Viton™ seals in preventing leaks is crucial for maintaining operational efficiency and safety, protecting against potential hazards such as explosive decompression or environmental contamination.

6. Applications in Industry

Pressure vessel closure with high-strength materials and Viton™ seals are also integral in industries like chemical processing, oil and gas, and water treatment.

Impact on Operational Safety and Efficiency:

- Chemical Processing. In reactors and storage tanks, these closures withstand aggressive chemicals and high pressures, ensuring safe containment and continuous operation.

- Oil and Gas. Used in separators and storage vessels, the closures handle extreme pressures and corrosive substances, also maintaining the integrity of the infrastructure.

- Water Treatment. For filtration systems and pressure vessels, closures endure varying pressures and environmental conditions, ensuring reliability and safety.

Hypothetical Scenario:

Imagine a pressure vessel in an offshore oil drilling platform. The vessel uses a stainless steel closure with Viton™ seals to prevent sea water corrosion and withstand the high pressures of the extracted oil and gas. Then the durability of the materials and the efficacy of the seals ensure continuous, safe operations even in this harsh environment, thereby exemplifying the critical role of well-chosen closure systems in maintaining operational safety and efficiency.

There are no reviews yet.