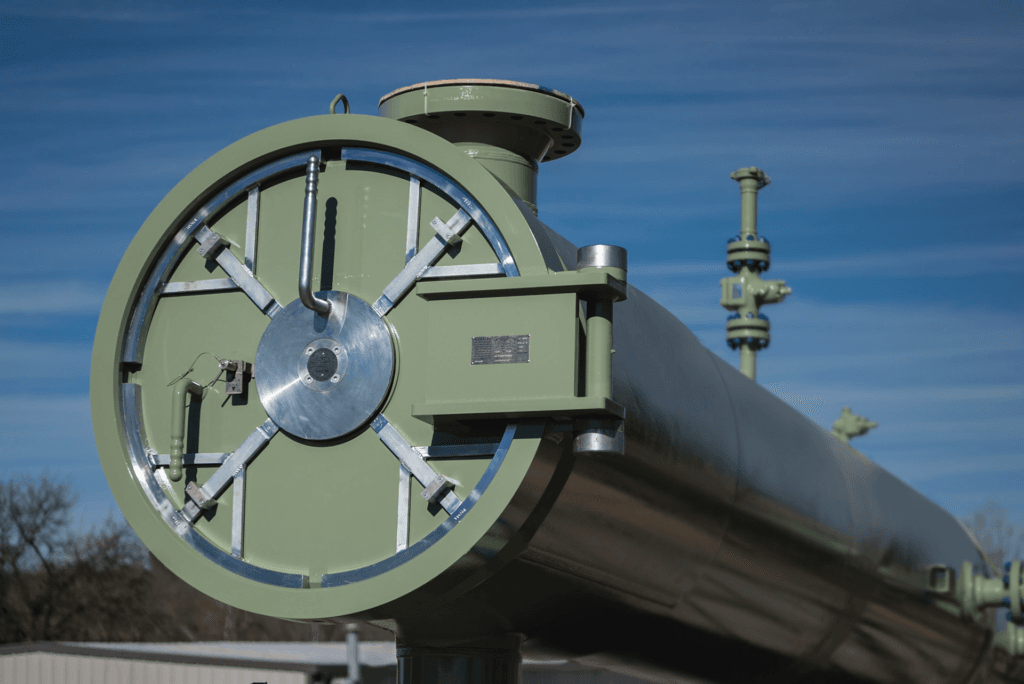

Pig trap closures are essential components designed specifically for the efficient and safe operation of pipeline pigging processes. These closures facilitate the insertion and retrieval of pipeline pigs, which are tools used to clean or inspect pipelines. Pig trap closures are engineered to provide quick access to the pipeline, enabling easy and safe pig launching and receiving.

Different Types of Pig Trap Closures

| Lock Ring Type | Band Type | Plug Buckle Type | |

| Installation | Vertical/Horizontal | Vertical/Horizontal | Vertical |

| Size | DN 200 to DN 1200 | DN 150 to DN 1000 | DN 150 to DN 1000 |

| Pressure | ASME #150 to #1500 | ASME #150 & #300 | ASME #150 to #600 |

| Materials | SA 350 LF2 | SA 350 LF2 | SA 516 70N/SA 105N |

| Sealing | Viton™ | Viton™ | Viton™ |

Technical indicators

| Technical indicators | |

| Nominal Diameter DN: | <1800mm |

| Design pressure PN: | ≤40 MPa |

| Working Medium: | oil, gas, water |

| Design Temperature: | -50℃~300℃ |

| Material: | 16Mn,A350LF2, A105, SS304, SS316, F51, F53, F55, INCONEL625, HASTELLOY C |

| Pipe Thickness: | 6mm~100mm |

1. Design and Functionality

Pig trap closures typically consist of a body flange, head cover, clamp, and seal. They incorporate a safety lock and an opening mechanism, which often includes a lever to simplify the operation. The design of these closures significantly reduces the difficulty of opening and closing end covers, saving time and labor and thereby boosting production efficiency. Unlike traditional bolt flanges, pig trap closures do not require the removal of bolts one by one. Instead, operators can open or close the cover by merely moving or rotating the lock slightly.

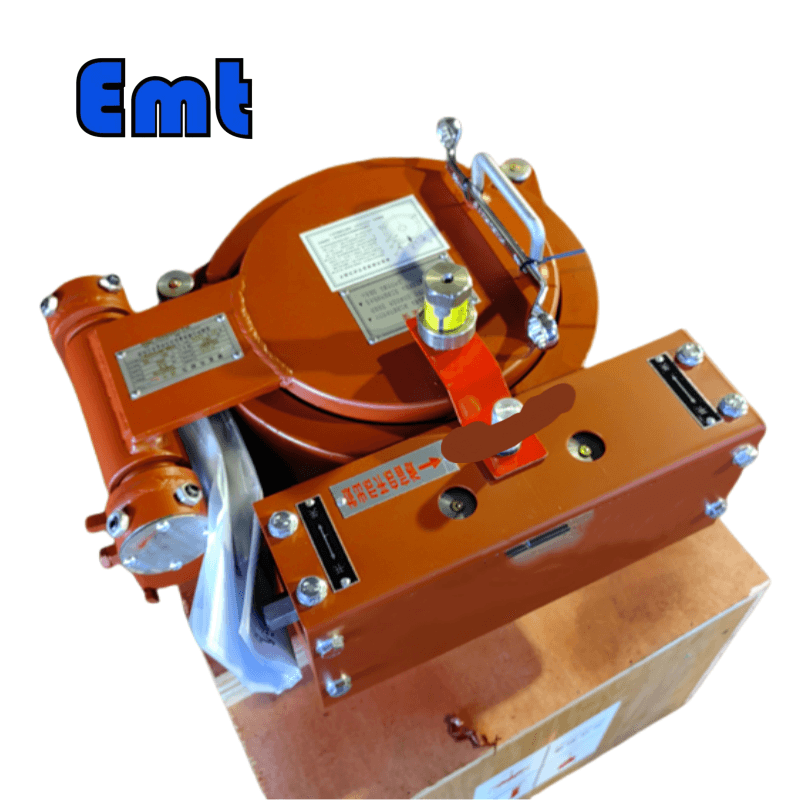

2. Types of Pig Trap Closures Offered by EMT

EMT provides various types of pig trap closures to accommodate different operational needs:

- Bayonet Type Closures. These closures feature a snap-open design for quick connection and disconnection, ideal for applications where frequent access is necessary.

- Lock Ring Type Closures. Known for their high safety and stability, these closures use a lock ring mechanism for fast opening and closing.

- Clamp Type Closures. These are secured with a clamping structure, offering easy operation and suitability for a variety of working conditions.

3. Material and Construction

Primary Construction Materials:

SA 350 LF2. This is a low-alloy steel known for its toughness and low-temperature properties, making it suitable for cold environments.

SA 516 70N/SA 105N. These are carbon steels that offer good mechanical properties and commonly work in high-pressure applications due to their robustness.

Pressure Handling Capabilities:

Pig trap closures are engineered to manage varying pressures, crucial for maintaining pipeline integrity under different operational conditions.

Models are available that can handle pressures ranging from ASME #150 to #1500, accommodating low to high-pressure systems.

Design Considerations:

The design of pig trap closures takes into account the need for easy access while ensuring secure closure to withstand the pipeline’s internal pressures.

The closures’ designe is to be robust yet operable with minimal effort, reflecting a balance between durability and usability.

4. Installation and Operation

Here’s an expanded step-by-step guide on how to install and operate these closures:

Preparation

- Assessment. Begin by assessing whether need to replace or repaire the existing closure. This involves checking the current state for any signs of wear or damage.

- Specification Confirmation. Confirm the specifications of the replacement or new closure, including size, material type, and compatibility with the existing pipeline system. This ensures the new closure will fit properly and function as intended.

Removal

- Safety Precautions. Prior to removal, ensure following all safety protocols. Depressurize the pipeline section if required to avoid any accidents.

- Loosening the Fastener. Identify the fastening mechanism used on the old closure—this could be a clamp, lock ring, or bayonet type. Use the appropriate tools to loosen and eventually remove the fastener.

- Closure Removal. Carefully remove the old closure from the pipeline. This might require some physical effort or the use of tools, depending on the size and weight of the closure.

Installation

- Positioning the New Closure. Place the new closure into the designated opening. Make sure it aligns perfectly with the existing pipeline markings to ensure a proper fit.

- Alignment Check. Double-check the alignment; misalignment can cause improper sealing and potential leaks.

Securing

- Attaching the Closure. Reattach the closure frame to the pipeline. This frame supports the closure and ensures it remains securely in place.

- Fastening. Secure the new closure using the chosen fastening system. Make sure it is tightened to the specifications recommended by the manufacturer to avoid any issues with pressure or leaks.

Inspection

- Initial Check. Once installed, visually inspect the closure to ensure it is firm and properly aligned.

- Testing. Perform a pressure test if necessary to validate the integrity of the installation. This test will help identify any leaks or weaknesses in the closure setup.

- Compliance Verification. Verify that the installation complies with all relevant safety and operational standards. This includes checking for any regulatory compliance required in your jurisdiction.

Operation

- Operational Training. Ensure that all personnel involved in operating the closure are trained on the specific type of pig trap closure installed. Understanding the operation mechanism is crucial for safe and efficient operation.

- Routine Checks. Implement a routine check-up schedule to monitor the condition of the closure as part of ongoing maintenance practices.

There are no reviews yet.