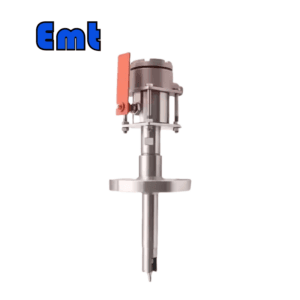

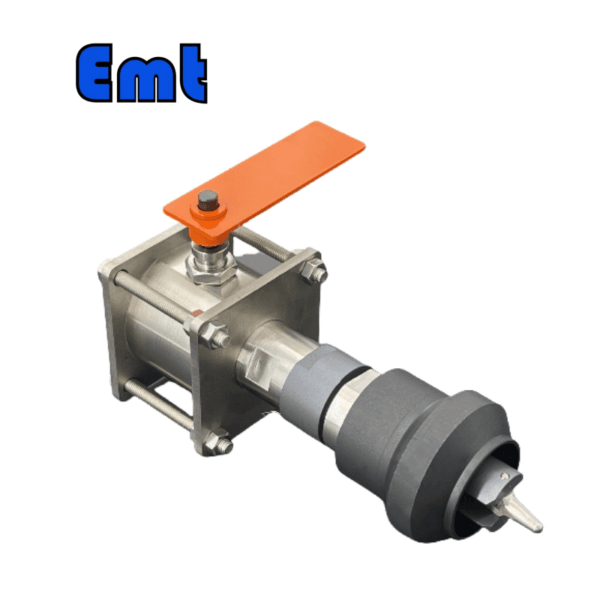

The EMT Pig Signaller-2” Welded Base with NPT Connection is a vital tool designed to monitor and detect pigs as they navigate through pipelines. This device is essential for the efficiency and safety of pipeline pigging operations. Its 2-inch welded base ensures sturdy and reliable mounting. The NPT (National Pipe Thread) connection offers a standard, secure fit. This ensures compatibility with most pipeline systems. Suitable for various industrial uses, harsh environments do not compromise the EMT Pig Signaller’s robust construction. It delivers precise, real-time tracking of pipeline pigs. This significantly enhances operational workflows and maintenance schedules. Whether utilized in oil, gas, or water pipelines, this pig signaler is a critical component for contemporary pipeline management.

Why Use a Pig Signaller

A Pig Signaller is essential for detecting and signaling the passage of pigs in pipelines, a key aspect of monitoring pigging operations. Positioned at key locations along the pipeline, these devices accurately confirm the pig’s location and progress, thereby enhancing both operational safety and efficiency. They provide precise information on the pig’s whereabouts, eliminating guesswork and reducing the risk of damage or loss of the pig.

Pig signallers also play a crucial role in confirming when a pig reaches important checkpoints or its final destination, which is essential for timing maintenance or further inspections. They help prevent pipeline blockages by signaling if a pig becomes lodged, ensuring continuous operations. Moreover, the data gathered from pig signallers is invaluable for planning preventive maintenance, which in turn enhances pipeline longevity and operational efficiency.

Applications

Pig signallers are vital for the maintenance and safety of pipelines. These devices are crucial in detecting when a cleaning or inspection pig passes a designated point, significantly aiding in the management and monitoring of pigging operations. They enable operators to verify the pig’s location, increasing operational safety by reducing guesswork and the risk of pipeline damage. Pig signallers also ensure the pig has successfully passed through specific sections, which is critical for scheduling maintenance or further inspections. This verification helps avoid premature maintenance work and pipeline blockages. By providing accurate location data, pig signallers support preventive maintenance strategies, contributing significantly to the pipeline’s efficiency and durability. Consequently, pig signallers are indispensable tools for ensuring smooth, safe, and efficient pipeline operations.

Specifications

| Name | Pig Indicator |

| Connection | 2” Welded Connection |

| Plug body length | 200mm |

| Operating temperature | -20~120℃/Meet customer requirements |

| NACE MR 01- 75 | Yes |

| Ingress protection | IP65/IP66 |

| Explosion-proof class | ExdⅡ BT4 |

| Remove under pressure | No |

| Trigger type | Bi-directional/Uni-directional |

| Adjustable length | 0 |

| Internal part material | 316SS/DSS/INCONEL |

| Insert depth | 21mm(Bi)/13mm(Uni) |

| Flange/Body material | PTFE coated A105N/304SS/316SS/DSS/INCONEL(As per MR) |

Advantages

The Pig Signaller-2” Welded Base with NPT Connection offers several advantages that make it an exceptional choice for pipeline operations. Here are some of the key benefits:

Robust Mounting

Sturdy 2-inch Welded Base: The robust welded base provides a secure and durable mounting point that ensures stability and longevity of the signaller in the pipeline, minimizing vibrations and potential damage during operations.

Standardized Connectivity

NPT (National Pipe Thread) Connection: This feature offers a standardized threading system, widely recognized in the industry, which ensures a secure and leak-proof fit. The NPT connection facilitates easy and reliable installation, compatible with most pipeline configurations, which simplifies the integration process.

Enhanced Operational Safety

Accurate Detection and Signaling: This signaller reliably detects and signals pig passages through pipelines. It closely monitors pigging operations, enhancing operational safety. By providing timely alerts, it eliminates uncertainties about the pig’s location.

Improved Pipeline Management

Prevents Blockages and Damage: The signaller helps to prevent potential pipeline blockages and mechanical damage by ensuring that any stuck pigs are quickly identified, allowing for prompt response to such issues.

Efficient Maintenance Scheduling

Supports Preventive Maintenance: By confirming the passage of pigs at critical points, the signaller allows for better scheduling of maintenance and inspections, which can prevent severe pipeline issues before they arise. This aids in optimizing maintenance cycles and reducing downtime.

Longevity and Durability

Built to Withstand Harsh Conditions: The signaller is designed to operate effectively in harsh conditions. It’s made from materials that resist wear and tear. This enhances its durability and reduces the need for frequent replacements.

There are no reviews yet.