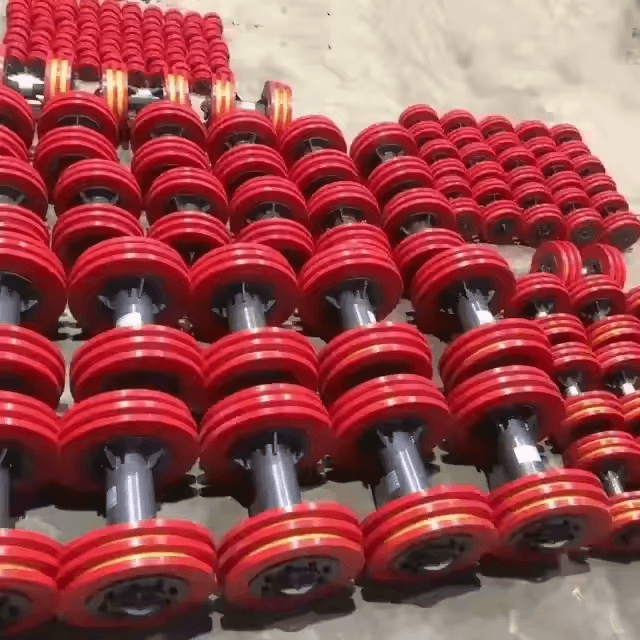

EMT Pigging, a leader in pipeline maintenance technology, has developed a range of pipeline pig scrapers designed to address the varied and demanding needs of the pipeline industry. The 4 Cups Pipe Cleaning Pig exemplifies their commitment to innovation and effectiveness in maintaining pipeline integrity across multiple sectors.

Product Overview

Name: 4 Cups Pipe Cleaning Pig

Brand Name: EMT Pigging

Material: Polyurethane, FKM (optional)

Steel Mandrel Material: Carbon Steel or Stainless Steel

Size Range: 2″ to 60″

Design Temperature: ≤90℃

Starting Pressure: 0.2~0.3 MPa

Running Distance: Up to 100 km

Usage: Pipeline pigging, drainage, water resistance, dielectric isolation

Certification: ISO9001

Condition: New

Key Features and Design of EMT’s Pig Scrapers

1.Materials and Customization:

The 4 Cups Pipe Cleaning Pig is constructed from premium polyurethane with an option for FKM, catering to different environmental and operational conditions. The versatility in material choices enables the pig to perform under a range of conditions — from standard to highly corrosive environments. The mandrel, available in either carbon steel or stainless steel, allows further customization. Stainless steel offers corrosion resistance crucial in acidic or saline environments often encountered in oil and gas extraction or processing, while carbon steel is suitable for less aggressive conditions, making it cost-effective for routine tasks.

2.Customizable Material Options:

Polyurethane:Known for its durability and flexibility, polyurethane is ideal for general pipeline cleaning tasks, offering excellent resistance to wear and abrasion. Its elasticity allows the pig to navigate bends and diameter changes within the pipeline without compromising its integrity.

FKM (Fluoroelastomer):For environments exposed to chemicals, such as hydrocarbons and solvents, FKM provides superior chemical resistance. This property is essential for maintaining the functionality of the pig in aggressive industrial applications where chemical exposure is a regular occurrence.

Name | Polyurethane Scraper Cup Pig Carbon Steel Pig For Oil&gas Pipeline Cleaning System | ||||

Material | Polyurethane | ||||

Light Density | 0.02-0.3g/m3 | ||||

Medium Density | 0.08-0.12g/m3 | ||||

Heavy Density | 0.13-0.16g/m3 | ||||

Feature | 1.High wear resistance | ||||

2.Good cleaning performance | |||||

3.Low cost | |||||

Payment | TT/LC | ||||

Advantage | 1.They are light weight and flexible. | ||||

2. Nice cleaning efficiency. | |||||

3.Accurate location tracking. | |||||

3.Robust Design

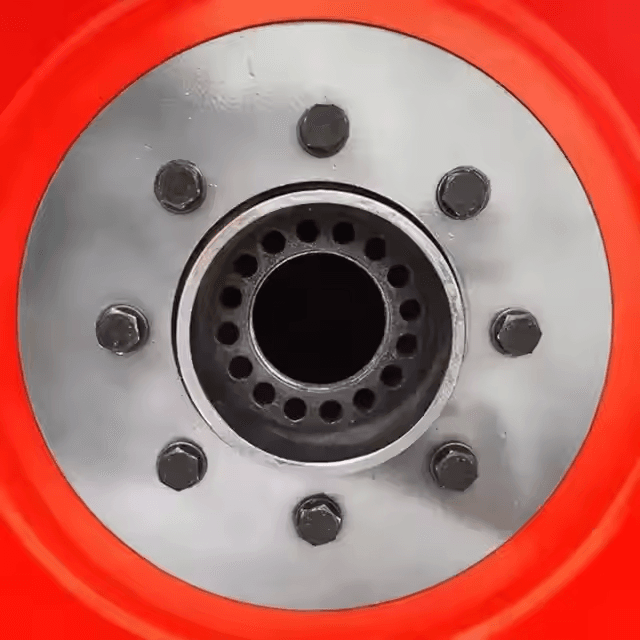

Four-Cup Structure:The innovative four-cup design of the EMT Pig enhances its ability to seal against the pipe wall, effectively removing all types of debris, including wax, scale, and sediment build-up. The cups are designed to maintain contact with the pipe walls, adapting to inconsistencies and ensuring a thorough cleaning process. This design not only improves the cleaning effectiveness but also extends the maintenance intervals by achieving more in a single pass.

4.Operational Efficiency

Low Starting Pressure and Long Travel Distance:Operating at a low starting pressure of 0.2 to 0.3 MPa, the pig requires less input energy to begin its journey, making it suitable for use in systems with limited pressure capabilities. The ability to travel up to 100 kilometers without the need for intermediate stops allows for uninterrupted cleaning of long pipeline sections. This capability is particularly beneficial for main transmission pipelines and subsea lines where access points may be spaced widely apart.

Maximizing Throughput:The efficiency of the 4 Cups Pipe Cleaning Pig directly translates to increased throughput and reduced downtime. By ensuring that pipelines remain clean and free of obstructions, the pig helps maintain optimal flow rates and pressures, crucial for the profitability and functionality of energy, mining, and utility operations.

Industrial Applications of EMT’s Pig Scrapers

1.Building Material Shops. In environments dealing with abrasive materials, the pig ensures pipelines are free from obstructions that could impact manufacturing processes.

2.Construction Works. Essential for maintaining drainage and sewage lines within construction sites, helping prevent blockages that can lead to project delays and additional costs.

3.Energy & Mining. The pig plays a pivotal role in ensuring that slurry and other residues do not compromise the integrity of pipelines, which is essential for uninterrupted production and safety.

4.Oil & Gas Pipeline Pigging. Specifically designed to tackle common issues such as wax, scale, and other organic deposits, ensuring that the flow of oil and gas is not impeded, which is critical for meeting production targets and regulatory safety standards.

Quality Assurance and Certification EMT’s Pig Scrapers

EMT’s commitment to quality is evident in its ISO9001 certification, which underscores a global standard of quality management practices. Each pig scraper undergoes rigorous testing, as evidenced by the provision of a machinery test report and a video outgoing-inspection, ensuring that each unit meets the highest standards of performance and reliability.

Packaging and Delivery

Single Package Size: 40X40X80 cm

Single Gross Weight: 1.000 kg

Packaging: Securely packed in plywood cases to ensure the product’s integrity during transportation.

EMT’s Pig Scrapers ,Your Choice

EMT’s 4 Cups Pipe Cleaning Pig represents a significant advancement in pipeline maintenance technology. With its robust design, material versatility, and operational efficiency, it stands out as a vital tool for industries that rely heavily on pipeline systems. By adopting such advanced solutions, companies can significantly enhance their operational efficiency, reduce downtime, and maintain the integrity of their pipeline infrastructure, ultimately contributing to smoother, more reliable operations and extended pipeline lifespans.

There are no reviews yet.