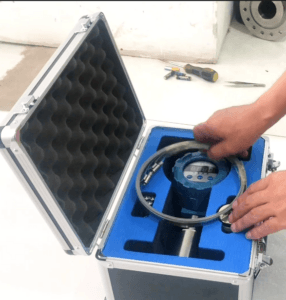

Our Pig Detector Non-intrusive device is engineered to minimize the need for direct physical modifications to the pipeline, thereby eliminating common risks such as leaks or structural damage. With easy installation and maintenance that doesn’t require pipeline shutdown, this tool significantly reduces operational downtime and costs. It supports a variety of pipeline materials and sizes, ensuring versatility across different applications.

The device offers real-time monitoring capabilities with high accuracy, ensuring immediate detection and precise location tracking of cleaning pigs or inspection gadgets within the pipeline. This level of monitoring is crucial for maintaining optimal pipeline flow and preventing blockages or maintenance issues that can lead to costly repairs or environmental hazards. EMT Company’s Pig Detector Non-intrusive is your solution for ensuring pipeline integrity and operational continuity with minimal intervention and maximum efficiency.

Function Description of The Pig Detector

This Pig Detector Non-intrusive device has three buttons: selection, adjustment, and confirmation. These manage four main functions: detection, query, reset, and time-adjusting.

For the Detection Function:

Start by pressing the selection button to check the battery and threshold settings. Pressing this button cycles through the four functions. Pressing it again turns off the light and puts the device into monitoring mode. Hit the confirmation button to start the detection. It shows the threshold and set values on the screen. To leave this mode, press the confirmation button again. Pressing the selection button turns off the light and returns the device to monitoring mode. If you don’t press any button for 3 seconds, the device will switch off the light and go back to monitoring on its own.

For the Query Function:

Press the selection button repeatedly to enter this mode. Then, press the confirmation button to see the pass rate. Press it again to check the last pig passing time. If there’s no data, the screen stays blank. Use the adjustment button to look up different times. To exit, set the count to zero using the adjustment button, then either press the selection button to pick another function or do nothing for 3 seconds to let it switch back to monitoring automatically.

For the Reset Function:

This function records each passing up to 99 times and resets after that. To reset manually, press the selection button, and then the confirmation button. The screen will show 00, and all records clear. The device then exits this mode automatically.

For the Time-Adjusting Function:

Press the selection button to start changing the time. Press the confirmation button, and the hour numbers will flash. Use the adjustment button to set the hour (it resets after 24). Press confirmation to switch to minutes, which also flash. Adjust the minutes (they reset after 60). Press confirmation again to save the new time. The device saves your settings automatically.

Setting Device Parameters (Avoid Random Adjustments)

Before adjusting the Pig Detector Non-intrusive device, make sure all the lights are off. Then, press the “select” button. When the “detection” light turns on, press the “confirm” button. You’ll first see the initial magnetic field detection value. After that, the device will show its alarm setting value. This alarm value ranges from 0 to 240. Lower numbers mean the device is more sensitive and might give more false alarms. Higher numbers make the device less sensitive but better at ignoring unrelated disturbances.

The device comes with preset settings ideal for your specific pipeline and magnet size, so it’s best not to change these settings without a specific reason. If you do need to make adjustments, press the adjustment button several times quickly—each four presses will change the level by one. To set a specific alarm value, keep pressing until you reach your desired number. Each press changes the value by 20. Once it hits 240, it will loop back to 0 and continue in increments of 20. When you’ve set it to the right value, press the “confirm” button to finish your adjustments.

Advantages of Pig Detector

Non-intrusive pig detectors provide several significant benefits for managing and maintaining pipelines. These detectors require no pipeline modifications, which minimizes the risk of leaks or damage. Installation and maintenance become simpler and quicker, reducing operational downtime. Additionally, these devices can operate without disrupting the pipeline, ensuring that maintenance is safer and more cost-effective.

The versatility of non-intrusive pig detectors allows them to work with various pipeline materials and sizes. They offer real-time monitoring, which is crucial for immediate pig detection and helps in making timely operational decisions. Moreover, their high accuracy in locating pigs ensures the effectiveness of cleaning or inspection processes. This helps maintain the overall integrity and efficiency of pipeline systems.

Our service

At EMT Company, we pride ourselves on delivering exceptional emergency medical technology and services tailored to meet the demands of modern healthcare and emergency response environments. Our innovative solutions are designed to enhance the efficiency and effectiveness of medical responders, providing them with the tools they need to save lives. We specialize in developing advanced medical devices, software, and systems that streamline operations, from patient monitoring to data management.

Our commitment extends beyond product development to include comprehensive training and support, ensuring that healthcare professionals are well-equipped to utilize our technology effectively during critical moments. With EMT Company, responders gain the reliability and precision necessary for optimal patient outcomes. Trust us to be your partner in advancing healthcare responsiveness and improving survival rates in emergencies. We are dedicated to innovation that empowers lifesavers everywhere.

There are no reviews yet.