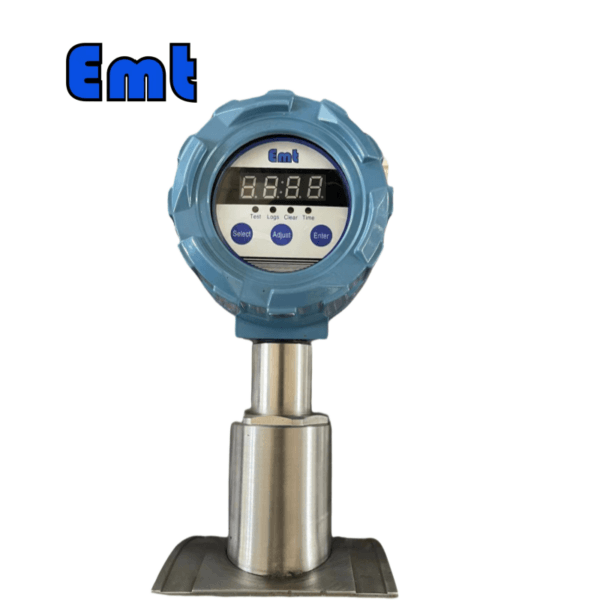

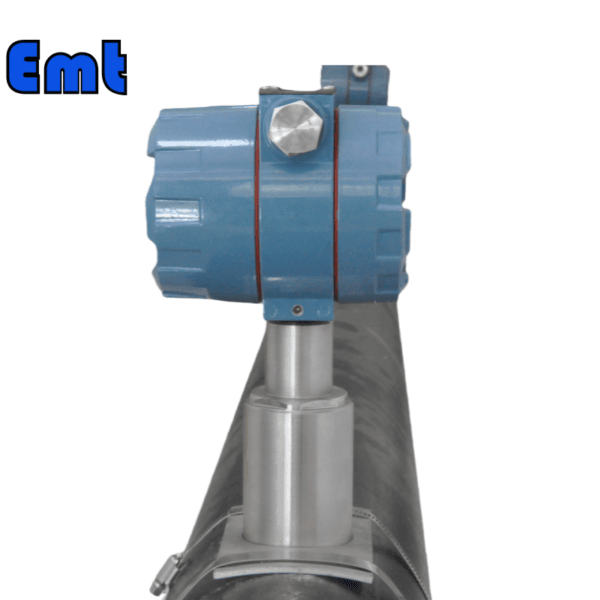

The Non-Intrusive Type Pig Signaler, also known as the magnetic explosion-proof passing indicator, includes several components. Firstly, it features an explosion-proof remote display mechanism. This mechanism comes with an LED that has a heating function, records the passing time, stores memory for 100 instances, supports remote transmission, and meets the explosion-proof mark dⅡBT6 with a protection level of IP65. Additionally, it encompasses a magnetic sensing mechanism and a removable card loading mechanism. Moreover, it includes connecting wires and an extension rod, which is generally necessary for buried pipelines. Finally, the core sensing mechanism of this device consists of a magnetic induction circuit, amplifier circuit, filter circuit, trigger circuit, and CPU. It also supports a remote switching circuit, display circuit, and reset circuit.

What is a Non-Intrusive Type Pig Signaler?

Non-Intrusive Type Pig Signaler is a device used by pipeline operations to detect the presence of a pig as it passes a certain point in the pipeline. This is essential for monitoring pigging operations, ensuring the pigs are moving as expected through the pipeline.

Specifications

| Name | Non-intrusive Pig Indicator |

| Operating Temperature | —39.8℃/80℃ |

| Operating Humidity | 41%~83% |

| Sensor Type | Magnetic Induction |

| Signal Switch Type | SPDT |

| Passing time | ±2s |

| Cleaning Pig Speed Range | 0.2-10 m/s |

| Switch Capacity | 2A |

| Reset Type | Auto Rese |

| Cable Joint Type | M20*1.5、 1/2NPT F |

| Explosion-Proof | Exd IICT6 Gb |

| IP Grade | IP65 |

How Does a Non-Intrusive Type Pig Signaler Work?

Non-intrusive pig signalers use various methods to detect pigs, such as magnetic, ultrasonic, or acoustic sensors. These sensors are installed on the outside of the pipeline and can sense the pig as it passes by detecting changes in physical phenomena like pressure, sound, or magnetic field. Here’s how it typically works:

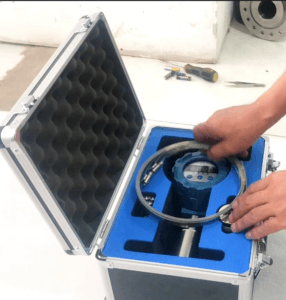

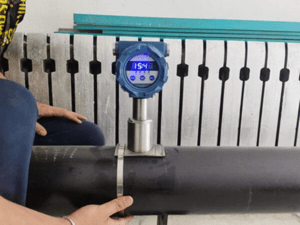

Sensor Installation: The sensor is mounted externally on the pipeline at a location where pig detection is required.

Detection Mechanism: As the pig passes the sensor location, it induces changes in the monitored parameters (like magnetic field disruptions or acoustic vibrations). Signal Transmission: Once the pig is detected, the sensor transmits a signal to a monitoring system, indicating the pig’s passage.

Data Analysis: Operators can analyze the transmitted data to confirm the pig’s location and status, helping to manage the pigging operation more effectively.

Benefits of Using Non-Intrusive Type Pig Signalers

Safety: By avoiding penetration of the pipeline, non-intrusive signalers enhance operational safety.

Ease of Installation: These devices can be installed without stopping pipeline operations or cutting into the pipeline.

Reduced Maintenance: Without direct contact with the internal pipeline environment, these signalers require less maintenance.

Versatility: They can be used on various types of pipelines, regardless of the product being transported.

Applications of Non-Intrusive Type Pig Signalers

Pipeline Cleaning and Maintenance: Monitoring cleaning pigs as they travel through the pipeline to remove deposits or other contaminants.

Inspection and Testing: Tracking inspection pigs are used to gather data on pipeline integrity and condition.

Batch Separation: Ensuring that different product batches do not mix in multi-product pipelines by indicating the passage of batching pigs.

EMT Intrusive Type Pig Signaler Indicator Types

| Indicator Types | ||||

| Indicator Types | A | B | C | D |

| Intrusive Type | Intrusive | Intrusive | Intrusive | Intrusive |

| Indicator Features | Popper Type | Manual reset flag | Manual reset flag combined with electrical signals | Date and time display combined with electrical signals |

Our EMT Service

Our EMT company proudly offers top-tier Non-Intrusive Pig Signalers. These devices detect pipeline pigs accurately without entering the pipeline. They utilize magnetic, ultrasonic, or acoustic sensors for reliable monitoring. Initially, clients find that installation is straightforward, requiring no pipeline modifications. Moreover, these signalers ensure safety by operating externally, greatly reducing risk during inspections. Additionally, their non-intrusive nature minimizes maintenance costs significantly. Importantly, they provide real-time data, enhancing operational decisions. Furthermore, our signalers adapt to various pipeline environments, proving their versatility. Lastly, we guarantee prompt customer support, ensuring swift resolution of any issues. Choose our Non-Intrusive Pig Signalers for efficient, safe pipeline monitoring solutions.

There are no reviews yet.