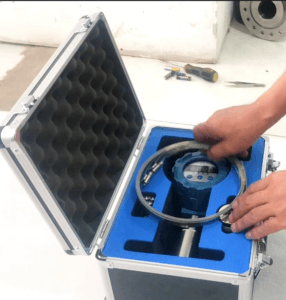

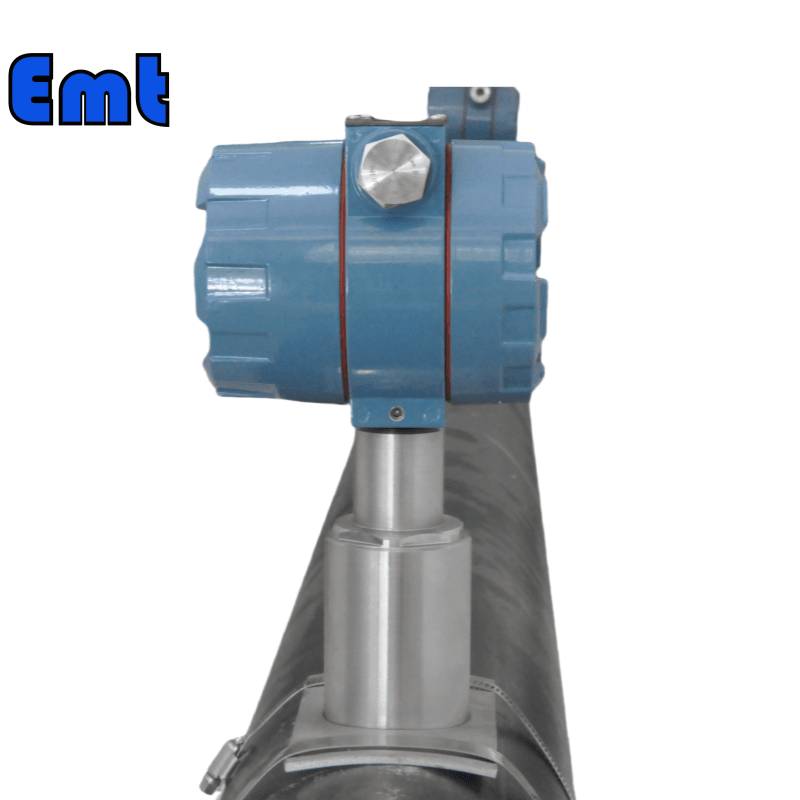

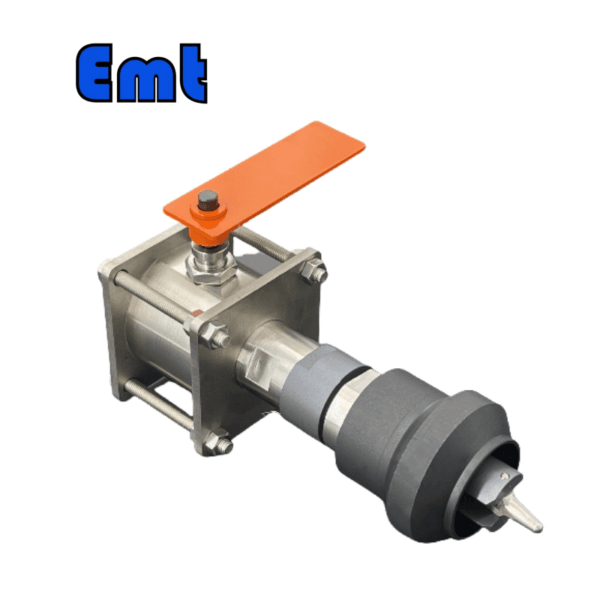

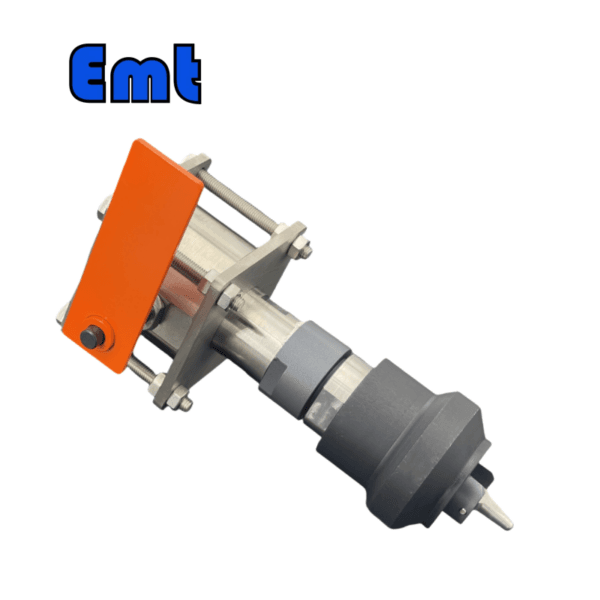

Non-intrusive pig detectors are essential tools that can enhance the efficiency and safety of pipeline operations, particularly in the oil and gas industry. Crafters make these devices from high-quality materials such as Stainless Steel 304, 316, Duplex Stainless Steel F51, Carbon Steel A105N, and Inconel 625. They engineer them to operate reliably in harsh, corrosive, and high-temperature environments. They offer a range of mounting options including 2-inch flange connections, welded nipples, and base-NPT nipple connections, accommodating various pipeline configurations. With operating temperatures ranging from -20°C to +120°C, these detectors are exceptionally versatile.

The functionality of non-intrusive pig detectors is enhanced by their diverse indicator and trigger types. Trigger types include manual reset flags, electrical switch outputs, digital displays, and both bi-directional and uni-directional triggers. These features make them suitable for detecting the presence and passage of pigs within pipelines without the need for direct contact with the medium being transported. This capability not only ensures enhanced operational safety and pipeline efficiency but also contributes to cost-effective maintenance and improved monitoring capabilities. Certified under ISO 9001, these detectors meet stringent quality standards, making them a reliable choice for maintaining the integrity and performance of pipeline systems.

Parameters

| Name | Non-intrusive Pig Detector |

| Operating Temperature | —39.8℃/80℃ |

| Operating Humidity | 41%~83% |

| Sensor Type | Magnetic Induction |

| Signal Switch Type | SPDT |

| Passing time | ±2s |

| Cleaning Pig Speed Range | 0.2-10 m/s |

| Switch Capacity | 2A |

| Reset Type | Auto Rese |

| Cable Joint Type | M20*1.5、 1/2NPT F |

| Explosion-Proof | Exd IICT6 Gb |

| IP Grade | IP65 |

Material Options:

Stainless Steel 304, 316: Offers excellent corrosion resistance.

Duplex Stainless Steel F51: Provides superior strength and corrosion resistance.

Carbon Steel A105N: Suitable for moderate temperatures and high-pressure environments.

Inconel 625: Ideal for extreme environments, resisting corrosion and high temperatures.

Operating Temperature Range:-20°C to +120°C

The operating temperature ensures reliable operation in a wide range of environmental conditions.

Certifications: ISO 9001 certified: Assures quality and reliability in design and manufacturing processes.

How Non-Intrusive Pig Detectors Work

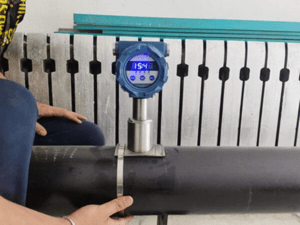

Non-intrusive pig detectors function by using external sensors to detect changes in pressure, acoustics, or magnetic fields as the pig passes a certain point along the pipeline. These sensors are mounted on the outside of the pipeline, eliminating the need for any breach in the pipeline integrity. This method greatly reduces the risk of leaks or contamination that can occur with intrusive systems.

Key Benefits of Non-Intrusive Pig Detectors

Safety: By avoiding penetration of the pipeline, these detectors significantly reduce the risk of accidents and environmental hazards.

Ease of Installation: You can install them without stopping pipeline operations, thereby avoiding any interruption to the flow of product.

Cost-Effectiveness: Reduces the need for pipeline modifications or shutdowns, which can be costly and time-consuming.

Versatility: Suitable for use on various types and sizes of pipelines, and adaptable to different pigging technologies.

Applications

Non-intrusive pig detectors work in a wide range of industries, including oil and gas, chemicals, and water treatment. They are particularly useful in applications where pipeline integrity is critical and where minimal disruption to operations is a priority. These detectors are also valuable in settings where traditional methods may pose safety risks, such as in high-pressure pipelines or in environments sensitive to contamination.

Conclusion

The non-intrusive pig detector is a highly effective and safe tool for the monitoring and maintenance of pipelines. Its ability to operate without compromising the pipeline’s structural integrity makes it an indispensable asset in modern pipeline operations, ensuring both operational efficiency and environmental safety.

There are no reviews yet.