The Mechanical Type Pig Signaller is a device used to detect the passage of pigs (pipeline inspection gauges) through oil, gas, and water pipelines. This type of signaller is mechanically operated, typically mounted directly on the pipeline, and provides a visual indication when a pig has passed the point where the signaller is installed.

Advantages

1. Simplicity

- Ease of Installation and Maintenance. Mechanical pig signallers are designed with a focus on straightforward mechanics. This simplicity is evident in their installation process, which usually involves minimal steps and can be performed quickly. Maintenance is similarly uncomplicated, primarily involving routine checks and basic mechanical repairs. Both of which do not require specialized electronic diagnostic tools or software.

- User-Friendly Operation. The operation of mechanical signallers does not require advanced training or technical knowledge. This also makes them accessible to a wide range of operators, ensuring that pipeline personnel can manage and troubleshoot the equipment with basic mechanical skills.

2. Reliability

- Reduced Component Failure. The mechanical nature of these signallers means they contain fewer electronic components that could fail. This reliability is critical in environments where electronic devices might suffer from issues related to power variability, wiring faults, or complex electronic malfunctions.

- Durability in Harsh Environments. Mechanical signallers are often more durable under extreme environmental condition. Such as high humidity, temperature fluctuations, and exposure to corrosive materials. So their robust construction helps prevent the common failures seen in more sensitive electronic devices.

- Consistent Performance. With a design that avoids reliance on electricity or sophisticated circuitry, mechanical pig signallers provide consistent performance. Then they are less likely to be affected by external electromagnetic fields or radio frequency interference, which can be prevalent in industrial settings.

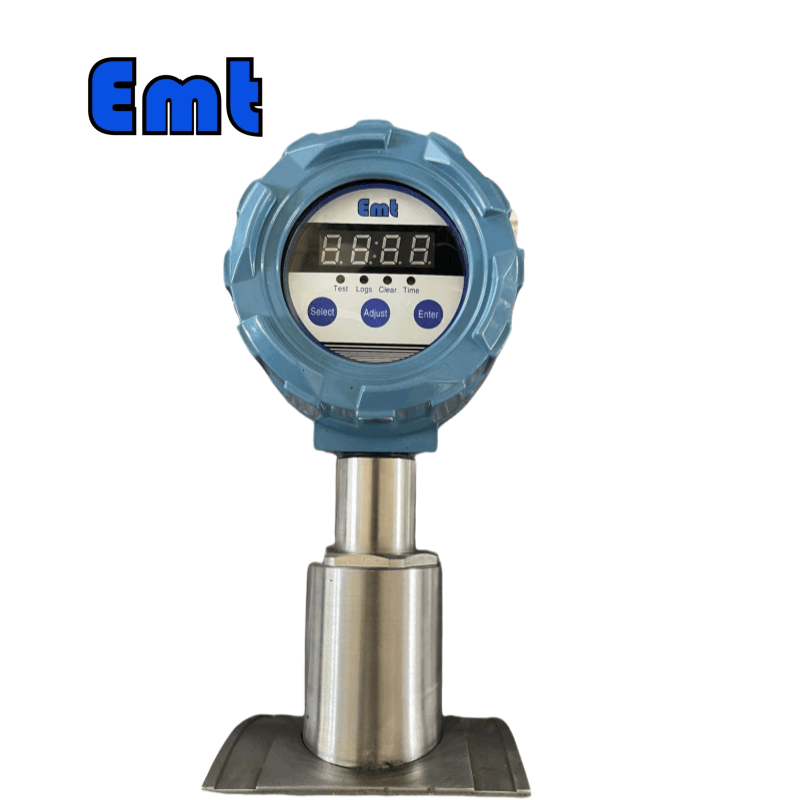

3. Immediate Visual Indication

- Quick Response to Pig Passage. The mechanical action in these signallers is direct and immediate. When a pig passes the trigger point, the mechanical indicator (such as a flag) visibly changes state. This change happens in real-time, allowing for prompt confirmation of the pig’s passage.

- No Need for Electronic Data Systems. Since the indication is purely mechanical, there is no need to integrate with electronic data systems or software for visual confirmation. This reduces complexity and eliminates the potential for digital errors or data misinterpretation.

- Visibility and Accessibility. The visual indicators on mechanical signallers are also designed to be seen from a distance, making them useful in large-scale industrial environments where electronic displays might not be easily visible. This accessibility ensures that all personnel in the vicinity can quickly ascertain the status of pigging operations without needing direct access to the signaller.

Safety and Maintenance Considerations

When installing and maintaining mechanical pig signallers, it is crucial to ensure that all mechanical connections are secure and that the device is checked regularly for any signs of wear or damage. Additionally, it’s important to avoid using magnetic materials near the signaller, as these could interfere with its operation if it is designed to be sensitive to magnetic fields for triggering purposes.

Maintenance Considerations

- Regular Inspection and Testing. Mechanical pig signallers should be inspected regularly for signs of wear or mechanical damage. Components such as springs, triggers, and indicator flags should be tested to ensure they operate correctly. Then these inspections help in identifying potential failures before they result in operational issues.

- Lubrication and Cleaning. Depending on the environment and the frequency of pigging operations, mechanical components may require lubrication to maintain smooth operation. Cleaning is also crucial to remove any debris or build-up that could impede the mechanical action of the signaller.

- Component Replacement. Over time, mechanical parts such as seals, springs, and the trigger mechanism may wear out and need replacement. Establishing a routine schedule for checking and replacing these components can prevent unexpected failures and maintain the reliability of the signaller.

- Documentation and Record Keeping. Keeping detailed records of maintenance, inspections, and any repairs or replacements carried out on the signaller can help track its reliability and performance over time. This documentation is also valuable for ensuring compliance with safety regulations and operational best practices.

- Training for Personnel. Ensuring that all operational personnel are trained not only in the installation and operation of the pig signallers but also in their maintenance and safety considerations is crucial. This training helps in preventing operational mishaps and enhances the longevity and effectiveness of the equipment.

How It Works

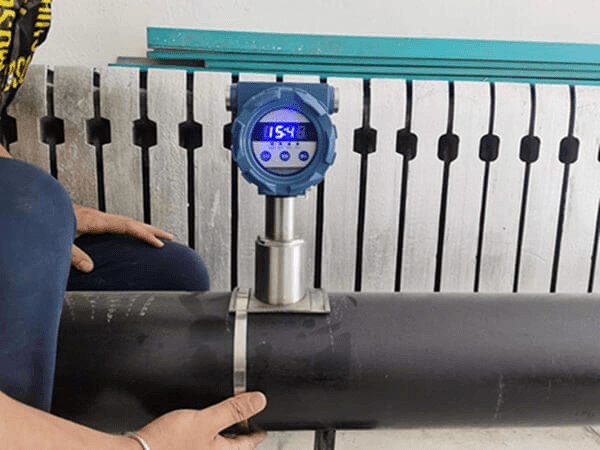

The Mechanical Type Pig Signaller operates using a mechanical trigger mechanism. When a pig passes through the pipeline, it physically impacts the trigger. Which is connected to an indicator flag or a mechanical arm on the exterior of the device. This action changes the position of the indicator, usually flipping a flag from one position to another to visually confirm the passage of the pig.

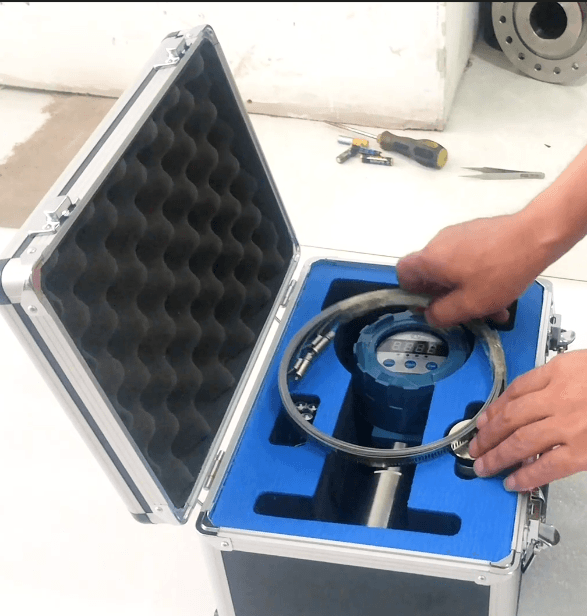

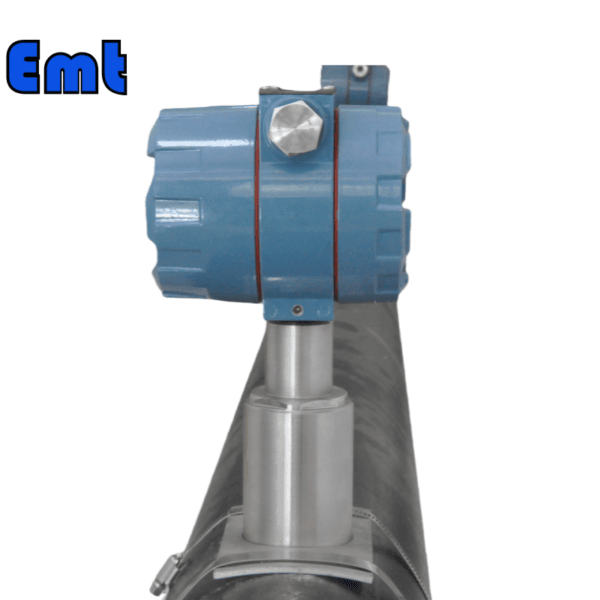

Design and Installation

The signaller is designed to be robust and simple, ensuring reliability under various pipeline conditions. It is typically encased in a sturdy metal housing to protect the internal mechanical components from external elements and pipeline debris. Then installation involves securing the device directly onto the pipeline where pig detection is required. So the installation site should be chosen carefully to avoid areas with high vibration or other mechanical impacts that could inadvertently trigger the device.

There are no reviews yet.