An intrusive pig detector is a device installed directly inside a pipeline. It detects the presence of a pig as it passes through. The detector’s design allows for accurate and reliable monitoring. It connects easily to the pipeline system, often using a flange fitting. This setup ensures a secure and leakage-free operation. Operationally, the device functions under a wide range of temperatures. It can handle extreme conditions, from very cold to quite hot. As the pig passes, the detector triggers a signal. This signal can be visual, auditory, or transmitted to a control system. These alerts help operators track the pig’s location accurately and in real time. Overall, the use of an intrusive pig detector enhances safety. It also increases the efficiency of the pigging operation. By providing timely data, it reduces the risk of pipeline damage. This tool is essential for maintaining smooth pipeline operations.

Different Types of Intrusive Pig Detectors

Pig Detector, Flange Connection

This pig detector is an intrusive model featuring a flange connection that complies with ASME B16.5 standards. It is designed with a standard 2” flange and a plug body that typically measures 200mm in length, although customization is available to meet specific customer requirements. The operating temperature for this device ranges from -20 to 120 degrees Celsius. It boasts an ingress protection rating of IP66 and meets the Exd II BT4 standard for explosion-proof classification. Importantly, it cannot be removed while under pressure.

| |

| Name | Pig Indicator |

| Connection | Flange Connection |

| Plug body length | 200mm |

| Operating temperature | —20~120℃/Meet customer requirements |

| NACE MR 01- 75 | Yes |

| Ingress protection | IP65/IP66 |

| Explosion-proof class | ExdⅡ BT4 |

| Remove under pressure | No |

| Trigger type | Bi-directional/Uni-directional |

| Adjustable length | 0 |

| Internal part material | 316SS/DSS/INCONEL |

| Insert depth | 21mm(Bi)/13mm(Uni) |

| Flange/Body material | PTFE coated A105N/304SS/316SS/DSS/INCONEL(As per MR) |

20mm Adjustable Pig Detector-Flange Connection

| |

| Name | 20mm Adjustable Pig Indicator |

| Connection | Flange Connection |

| Plug body length | 200mm |

| Operating temperature | —20~120℃/Meet customer requirements |

| NACE MR 01- 75 | Yes |

| Ingress protection | IP65/IP66 |

| Explosion-proof class | ExdⅡ BT4 |

| Remove under pressure | No |

| Trigger type | Bi-directional/Uni-directional |

| Adjustable length | 20mm |

| Internal part material | 316SS/DSS/INCONEL |

| Insert depth | 21mm(Bi)/13mm(Uni) |

| Flange/Body material | PTFE coated A105N/304SS/316SS/DSS/INCONEL(As per MR) |

Removable Pig Indicator, 2” Welded Base, NPT Connection

| |

| Name | Removable Pig Indicator |

| Connection | 2” Welded Base, NPT Connection |

| Plug body length | 200mm |

| Operating temperature | -20~120℃/Meet customer requirements |

| NACE MR 01- 75 | Yes |

| Ingress protection | IP65/IP66 |

| Explosion-proof class | ExdⅡ BT4 |

| Remove under pressure | Yes |

| Trigger type | Bi-directional/Uni-directional |

| Adjustable length | 20mm |

| Internal part material | 316SS/DSS/INCONEL |

| Insert depth | 21mm(Bi)/13mm(Uni) |

| Base/Body material | PTFE coated A105N/304SS/316SS/DSS/INCONEL(As per MR) |

Pig Signaler- 2” Base Welded

The welded base pig indicator has a 2” base welded connection and is typically made from the same material as the pipe. This ensures a strong, cohesive weld that minimizes weak points, leading to a more secure and leak-proof operation. A welded base enhances the structural integrity of the indicator, allowing it to handle high pressures and aggressive substances in the pipeline. Its robust construction reduces maintenance needs and extends its service life, making it a cost-effective option for long-term pipeline monitoring.

| |

| Name | Pig Indicator |

| Connection | 2” Welded Connection |

| Plug body length | 200mm |

| Operating temperature | -20~120℃/Meet customer requirements |

| NACE MR 01- 75 | Yes |

| Ingress protection | IP65/IP66 |

| Explosion-proof class | ExdⅡ BT4 |

| Remove under pressure | No |

| Trigger type | Bi-directional/Uni-directional |

| Adjustable length | 0 |

| Internal part material | 316SS/DSS/INCONEL |

| Insert depth | 21mm(Bi)/13mm(Uni) |

| Flange/Body material | PTFE coated A105N/304SS/316SS/DSS/INCONEL(As per MR) |

Removable Pig Indicator On a Flange Valve

| |

| Name | Removable Pig Indicator On a Flange Valve |

| Connection | Flange Connection |

| Plug body length | 200mm |

| Operating temperature | -20~120℃/Meet customer requirements |

| NACE MR 01-75 | Yes |

| Ingress protection | IP65/IP66 |

| Explosion-proof class | ExdⅡ BT4 |

| Remove under pressure | Yes |

| Trigger type | Bi-directional/Uni-directional |

| Adjustable length | 0 |

| Internal part material | 316SS/DSS/INCONEL |

| Insert depth | 21mm(Bi)/13mm(Uni) |

| Flange/Body material | PTFE coated A105N/304SS/316SS/DSS/INCONEL(As per MR) |

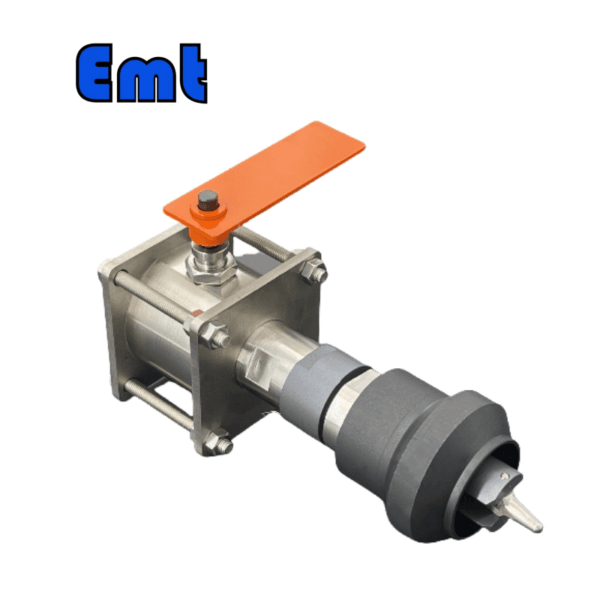

Removable Pig Indicator with a Ball Valve

| |

| Name | Removable Pig Indicator with a Ball Valve |

| Connection | Flange Connection |

| Plug body length | 200mm |

| Operating temperature | -20~120℃/Meet customer requirements |

| NACE MR 01- 75 | Yes |

| Ingress protection | IP65/IP66 |

| Explosion-proof class | ExdⅡ BT4 |

| Remove under pressure | Yes |

| Trigger type | Bi-directional/Uni-directional |

| Adjustable length | 0 |

| Internal part material | 316SS/DSS/INCONEL |

| Insert depth | 21mm(Bi)/13mm(Uni) |

| Flange/Body material | PTFE coated A105N/304SS/316SS/DSS/INCONEL(As per MR) |

Removable Pig Indicator with a DBB Valve

The DBB valve ensures a fail-safe seal, allowing maintenance without stopping the flow. It isolates the indicator for safe, live-line interventions. The installation process is user-friendly, which shortens setup time. Its robust design promises longevity, even under high pressure. The indicator provides a clear visual signal when a pig passes. This design enhances safety and boosts operational efficiency. It also reduces downtime and cuts costs, optimizing pipeline management.

| |

| Name | Removable Pig Indicator with a DBB Valve |

| Connection | Flange Connection |

| Plug body length | 200mm |

| Operating temperature | -20~120℃/Meet customer requirements |

| NACE MR 01- 75 | Yes |

| Ingress protection | IP65/IP66 |

| Explosion-proof class | ExdⅡ BT4 |

| Remove under pressure | Yes |

| Trigger type | Bi-directional/Uni-directional |

| Adjustable length | 0 |

| Internal part material | 316SS/DSS/INCONEL |

| Insert depth | 21mm(Bi)/13mm(Uni) |

| Flange/Body material | PTFE coated A105N/304SS/316SS/DSS/INCONEL(As per MR) |

There are no reviews yet.