The EMT-SI Injection Quills are essential components designed for use in chemical injection applications within pipelines. These devices facilitate accurate and efficient delivery of chemicals into a pipeline system, essential for maintenance and monitoring operations. Here is a detailed summary of the key attributes and specifications of the EMT-SI Injection Quills:

1. Key Attributes of Injection Quills

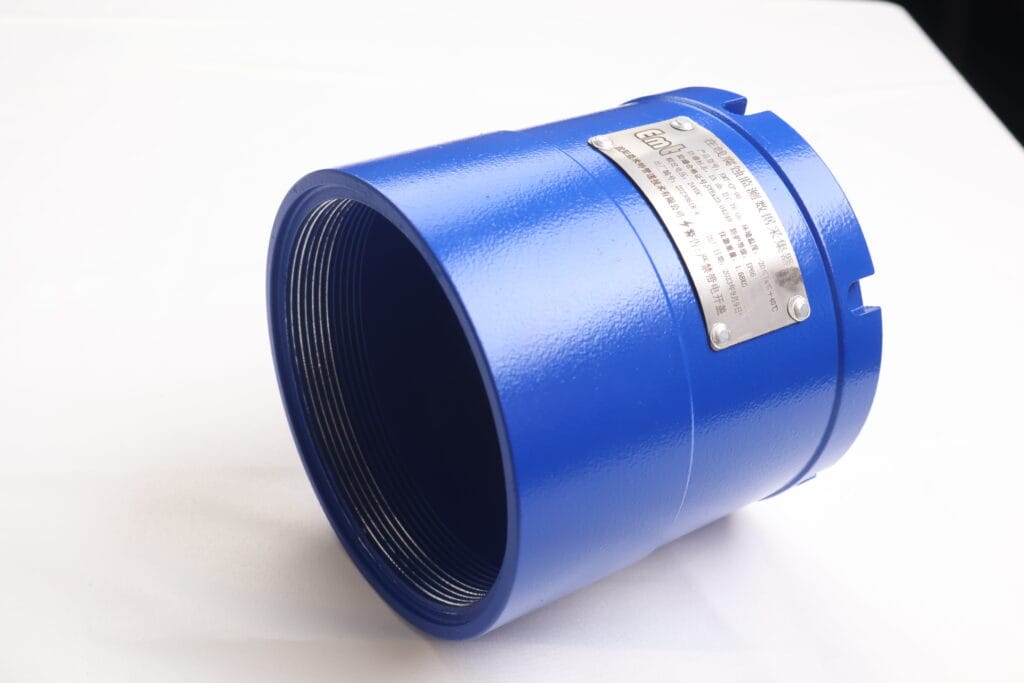

- Place of Origin: Liaoning, China

- Brand Name: Emt

- Customized Support: Offers OEM, ODM, and OBM services, allowing for customization in design and functionality to meet specific client needs.

- Material Options: Available in various materials including Carbon Steel, Stainless Steel 304, Stainless Steel 316, Duplex Stainless Steel (DSS F51), Carbon Steel A105N, and Inconel 625, to suit different environments and chemical compatibility requirements.

- Size Range: Sizes available from 1/2″ to 4″, with options for customization to fit specific pipeline configurations.

- Pressure Ratings: Designed to handle high-pressure applications, ensuring durability and reliability under stress.

- Certifications: Certified to ISO 9001 standards, ensuring quality and compliance with international regulations.

2. Features and Benefits of EMT-SI Injection Quills

Ease of Operation

The EMT-SI Injection Quills are engineered for straightforward operation, significantly simplifying the process of chemical injection into pipelines. This simplicity:

- Reduces Complexity: The design minimizes the number of components and adjustments needed, allowing for quick and error-free operation.

- Enhances Usability: With user-friendly controls and clear instructions, operators can easily manage the system without specialized training.

- Speeds Up Integration: The quills are designed to be compatible with existing pipeline setups, facilitating fast installation and integration without extensive downtime.

High Accuracy and Efficiency

Precision and efficiency are at the core of the EMT-SI Injection Quills’ functionality, offering:

- Precise Chemical Dosing: The quills are calibrated to deliver exact amounts of chemicals, ensuring that the correct dosage is used each time, which is vital for the chemical processes and the safety of the pipeline.

- Effective Dispersion: The design ensures optimal dispersion of chemicals within the pipeline, which is crucial for preventing corrosion and ensuring the uniform effectiveness of the treatment across the entire system.

- Maintenance of Pipeline Integrity: By ensuring both accurate dosing and effective dispersion, the quills help maintain the structural integrity and operational performance of pipelines, thereby preventing costly repairs and downtime.

Cost-Effectiveness

The EMT-SI Injection Quills are designed to provide a cost-effective solution for pipeline maintenance, characterized by:

- Low Initial Cost: These quills offer an economical option compared to other injection systems, with competitive pricing that makes them accessible for a wide range of budgets.

- High Durability: Constructed from materials like carbon steel or stainless steel, the quills are built to last, reducing the need for frequent replacements and lowering the total cost of ownership.

- Minimized Operational Costs: By optimizing chemical usage and reducing the frequency of maintenance interventions, the quills help keep ongoing operational costs low, enhancing overall efficiency and cost savings over time.

3. Order Information

Access Fitting Body

| Model | ||||||

| EMT-CIPA | Injection Quills | |||||

| – The material of Access Fitting Body | ||||||

| 0 | CS | |||||

| 1 | 316SS | |||||

| 2 | 316LSS | |||||

| 3 | DUPLEX SS | |||||

| The Type of Access Fitting Body | ||||||

| B | 2″Welded(suffix “pressure rating” can be added to B) | |||||

| F | 2″ANSI Flange(suffix “pressure rating & sealing type” can be added to F) | |||||

| -Tee Size- pressure rating & sealing type if flanged end | ||||||

| 0 | No Tee | |||||

| 1 | 1/4″NPT(F)Tee | |||||

| 2 | 1/2″NPT(F)Tee | |||||

| 3 | 3/4″NPT(F)Tee | |||||

| 4 | 1″NPT(F)Tee | |||||

| 5 | Hole for 1/4″SWN Flange | |||||

| 6 | Hole for 1/2″SWN Flange | |||||

| 7 | Hole for 3/4″SWN Flange | |||||

| 8 | Hole for 1″SWN Flange | |||||

| -Protective Cover Type/ Material | ||||||

| 0 | No Protective Cover | Material | ||||

| 1 | Without hole | CS or 0 | ||||

| 2 | With hole | SS or 1 | ||||

| 3 | Bleed Valve | DSS or 3 | ||||

| 4 | Bleed Valve, & Pressure Gauge | |||||

| For Example:EMT-CIPA-0F600#RF-2-1/CS shows 2″ANSI 600#RF Flange Access Fitting Body in CS, 1/2″NPT(F)Tee, Protective Cover in CS without hole 0F600#RF: 0F_ Access Fitting Body is Flanged in CS , 600#RF _Size is 2″ANSI 600#RF , 2:Tee size is 1/2NPT(F) 1: Protective cover type is without hole /CS: Protective cove material in CS | ||||||

Sampler & Injector

| Model | |||||||||||||||||||||||||

| SI | Sampler & Injector | ||||||||||||||||||||||||

| -Code | Plug | ||||||||||||||||||||||||

| Pxxx | Type | Material | Sealing Material | ||||||||||||||||||||||

| 0 | No Request | 0 | CS | 0 | No Request | ||||||||||||||||||||

| 1 | Hollow Plug Body | 1 | 316SS | 3 | DSS | 1 | Viton O-Ring / PTFE Primary Packing | ||||||||||||||||||

| 2 | Solid Plug Body | 2 | 316LSS | 4 | INCONEL | 2 | HNBR | ||||||||||||||||||

| – Code | Injection Nut | ||||||||||||||||||||||||

| Nxx | Connection Size | Material | |||||||||||||||||||||||

| 0 | No Request | 0 | CS | ||||||||||||||||||||||

| 1 | 1/4″ | 1 | 316SS | 3 | DSS | ||||||||||||||||||||

| 2 | 1/2″ | 2 | 316LSS | 4 | INCONEL | ||||||||||||||||||||

| – Code | Sampling & Injection Tube | ||||||||||||||||||||||||

| Sxxx-Lx″ | Connection Size | Material | Nozzle | Line size(x″) | |||||||||||||||||||||

| 0 | No Request | 0 | CS | 0 | No Request | The most effective position for injection is generally at the center of the pipe | |||||||||||||||||||

| 1 | 1/4″ | 1 | 316SS | 1 | Open | ||||||||||||||||||||

| 2 | 1/2″ | 2 | 316LSS | 2 | Quill | ||||||||||||||||||||

| 3 | DSS | 3 | Cap & Core | ||||||||||||||||||||||

| 4 | INCONEL | ||||||||||||||||||||||||

| – Code | Type and Size of components connected to Tee and material of components | ||||||||||||||||||||||||

| Txx | Connection Size | Material | |||||||||||||||||||||||

| 0 | No Request | 0 | CS | ||||||||||||||||||||||

| 1 | 1/4″Nipple | a | 1/4″Nipple and Valve | 1 | 316SS | ||||||||||||||||||||

| 2 | 1/2″Nipple | b | 1/2″Nipple and Valve | 2 | 316LSS | ||||||||||||||||||||

| 3 | 3/4″Nipple | c | 3/4″Nipple and Valve | 3 | D SS | ||||||||||||||||||||

| 4 | 1″Nipple | d | 1″Nipple and Valve | 4 | INCONEL | ||||||||||||||||||||

| 5 | 1/4″SWN Flange* | e | 1/4″Nipple and Flange | ||||||||||||||||||||||

| 6 | 1/2″SWN Flange | f | 1/2″Nipple and Flange | ||||||||||||||||||||||

| 7 | 3/4″SWN Flange | g | 3/4″Nipple and Flange | ||||||||||||||||||||||

| 8 | 1″SWN Flange | h | 1″Nipple and Flange | ||||||||||||||||||||||

| For Example:SI-P221-N12-S122-L4″-T22 SI:Sampling & Injection Assembly,P221: Solid Plug Body in 316LSS Viton O-Ring and PTFE Primary Packing,N12:Injection Nut Connection Size is 1/4″and Material is 316LSS,S122:Injection Tube Connection Size is 1/4″ and Material is 316LSS.Type of nozzle is quill,L4″:For 4″pipe. T22: Connection Size of Nipple connected to Tee is 1/2″NPT(M), Nipple material is 316LSS | |||||||||||||||||||||||||

Note: SWN Flange is special WN Flange

Example for a set of Sampler & Injector Assembly:

EMT-CIPA-0F600#RF-2-1+ SI-P221-N12-S122-L4″-T22

4. Product Composition of Injection Quills

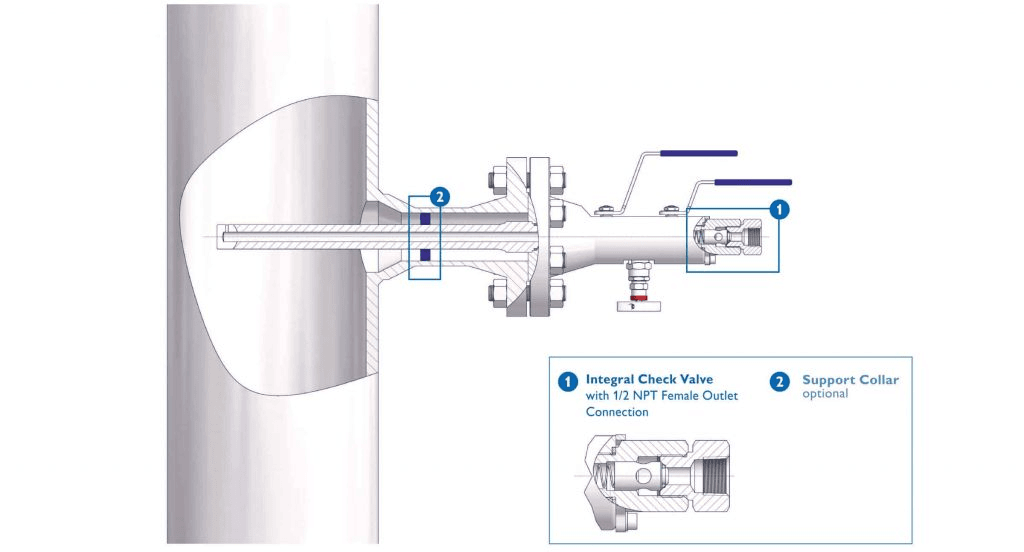

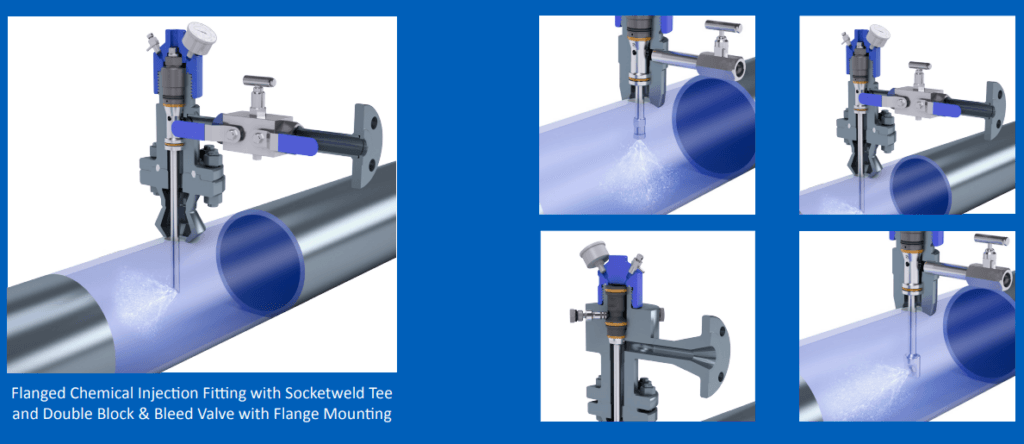

- Access Fitting Body: Available in two standard mounting configurations (weld mounting and flanged mounting) and two types (No Tee Type and Tee Type), allowing for flexibility in application and installation.

- Access Fitting Plug: Used to connect corrosion coupons or chemical injection components like the injection quill, ensuring secure and effective placement within the pipeline.

- Protect Cover: Provides physical protection to the internal components, maintaining integrity and functionality of the fitting.

5. Packaging and Delivery

- MOQ: Available from 1 set, accommodating both large-scale and smaller, specialized applications.

- Packaging: Securely packed in a plywood case to ensure safe transportation.

- Delivery Port: Dalian, China

- Packaging Size and Weight: Each package measures 40X20X60 cm with a gross weight of 3.000 kg per item.

There are no reviews yet.