Briefly Introduction to Industrial Pipe Cleaning

Maintaining clean pipes is crucial across various industries, including oil and gas, water treatment, and manufacturing, as it ensures operational efficiency, safety, and regulatory compliance. In the oil and gas industry, clean pipelines prevent the buildup of wax, scale, and corrosion, which can restrict flow, increase pressure, and lead to costly leaks or failures. In water treatment plants, clean pipes are essential to maintaining water purity, preventing biofilm formation, and ensuring uninterrupted supply. The manufacturing sector relies on well-maintained pipelines to transport raw materials, chemicals, and finished goods efficiently, avoiding production downtime and equipment damage.

Neglecting pipe maintenance can lead to severe risks such as blockages, contamination, and system failures. Blockages caused by debris, mineral deposits, or chemical residues can reduce flow efficiency, increase energy consumption, and cause unexpected shutdowns. Contamination is particularly dangerous in food, pharmaceutical, and water industries, as it can result in unsafe products, regulatory violations, and legal consequences. In extreme cases, pipe neglect can lead to corrosion, leaks, or even catastrophic failures, resulting in hazardous spills, environmental damage, and costly repairs. Regular pipe cleaning and maintenance help industries avoid these risks, ensuring smooth operations, product integrity, and compliance with safety standards.

Importance

Industrial pipe cleaning is a critical maintenance process that ensures the smooth operation of pipelines across various industries, including oil and gas, food processing, pharmaceuticals, and water treatment. Keeping pipelines clean offers numerous benefits, including improved efficiency, safety, and compliance with regulations.

Common Methods of Industrial Pipe Cleaning

a) Mechanical Cleaning

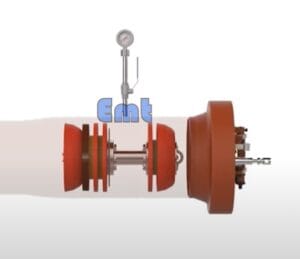

Mechanical methods physically remove debris and buildup from pipes. One widely used technique is pigging, where pipeline pigs—devices made of foam, rubber, or metal—are inserted into the pipeline to scrape off deposits and inspect conditions. Additionally, scrapers and brushes are used to manually or mechanically remove scale, sludge, and other contaminants, making them effective for industries dealing with solid or semi-solid residues.

b) Chemical Cleaning

When mechanical methods are insufficient, chemical solutions help dissolve stubborn contaminants. Solvent cleaning uses specialized chemicals to break down grease, rust, and mineral deposits, restoring pipe efficiency. Acid cleaning is particularly effective for removing hard scale and corrosion, commonly used in industries that handle water and chemicals. To address environmental concerns, many companies now opt for biodegradable and eco-friendly chemicals, which clean effectively without harming ecosystems.

c) High-Pressure Cleaning

For pipelines with significant buildup, high-pressure techniques provide an efficient solution. Hydro jetting uses powerful water jets to dislodge debris, remove blockages, and clean pipe walls thoroughly. Meanwhile, steam cleaning is ideal for eliminating grease and oil residues, often used in food processing and manufacturing plants.

d) Ultrasonic and Advanced Cleaning Methods

Advanced technologies further enhance cleaning efficiency. Ultrasonic cleaning uses high-frequency sound waves to break down contaminants, making it effective for delicate or intricate pipelines. Additionally, electromagnetic cleaning is used in specialized industries where precision and minimal disruption are required.

There are no reviews yet.