Introduction

A hydraulic chemical injection quill precisely injects chemicals into a process stream under high pressure. It suits modern industrial systems that require direct, controlled chemical dosing. The quill’s design allows for integration into the process medium, ensuring efficient mixing and reaction. Suitable for various applications, it is essential for maintaining chemical processes and treatment effectiveness.

To enhance functionality, these quills can incorporate features like integral check valves. These valves prevent backflow, securing the process stream’s integrity. Manufacturers offer options in materials like Carbon Steel, Stainless Steel, or Exotic Alloys, catering to specific environmental conditions. Additionally, systems can be configured as Simplex or Duplex, with options for Duty or Standby operations, making them adaptable to diverse operational requirements.

- Product Name: EMT Hydraulic Chemical Injection Quill

- Brand Name: EMT Pigging

- Condition: Brand New

- Type: Advanced Injection Quill & Sampling System

- Certification: ISO9001 certified, which ensures international quality standards

- Place of Origin: Shenyang City, Liaoning Province, China

- Warranty: Generous 1.5-year warranty, reflecting our commitment to quality

- Selling Units: Individually packaged for optimal protection

- Application: Specifically for high-efficiency pipeline corrosion prevention

Selection Model of The Product

| Model | |||||||||||||||||||||||||||

| SI | Chemical Injector Quill | ||||||||||||||||||||||||||

| -Code | Plug | ||||||||||||||||||||||||||

| Pxxx | Type | Material | Sealing Material | ||||||||||||||||||||||||

| 0 | No Request | 0 | CS | 0 | No Request | ||||||||||||||||||||||

| 1 | Hollow Plug Body | 1 | 316SS | 3 | DSS | 1 | Viton O-Ring / PTFE Primary Packing | ||||||||||||||||||||

| 2 | Solid Plug Body | 2 | 316LSS | 4 | INCONEL | 2 | HNBR | ||||||||||||||||||||

| – Code | Injection Nut | ||||||||||||||||||||||||||

| Nxx | Connection Size | Material | |||||||||||||||||||||||||

| 0 | i.e. No Request | 0 | i.e. CS | ||||||||||||||||||||||||

| 1 | i.e. 1/4″ | 1 | i.e. 316SS | 3 | i.e. DSS | ||||||||||||||||||||||

| 2 | i.e. 1/2″ | 2 | i.e. 316LSS | 4 | i.e. INCONEL | ||||||||||||||||||||||

| – Code | Injection Tube | ||||||||||||||||||||||||||

| Sxxx-Lx″ | Connection Size | Material | Nozzle | Line size(x″) | |||||||||||||||||||||||

| 0 | No Request | 0 | CS | 0 | i.e. No Request | The most effective position for injection is generally at the center of the pipe | |||||||||||||||||||||

| 1 | i.e. 1/4″ | 1 | i.e. 316SS | 1 | i.e. Open | ||||||||||||||||||||||

| 2 | i.e. 1/2″ | 2 | i.e. 316LSS | 2 | i.e. Quill | ||||||||||||||||||||||

| 3 | i.e. DSS | 3 | i.e. Cap & Core | ||||||||||||||||||||||||

| 4 | i.e. INCONEL | ||||||||||||||||||||||||||

| – Code | Nipple and Valve(or end Flange)of Tee | ||||||||||||||||||||||||||

| Txx | Connection Size | Material | |||||||||||||||||||||||||

| 0 | i.e. No Request | 0 | i.e. CS | ||||||||||||||||||||||||

| 1 | i.e. 1/4″Nipple | a | i.e. 1/4″Nipple and Valve | 1 | i.e. 316SS | ||||||||||||||||||||||

| 2 | i.e. 1/2″Nipple | b | i.e. 1/2″Nipple and Valve | 2 | i.e. 316LSS | ||||||||||||||||||||||

| 3 | i.e. 3/4″Nipple | c | i.e. 3/4″Nipple and Valve | 3 | i.e. D SS | ||||||||||||||||||||||

| 4 | i.e. 1″Nipple | d | i.e. 1″Nipple and Valve | 4 | i.e. INCONEL | ||||||||||||||||||||||

| 5 | i.e. 1/4″Flange | e | i.e. 1/4″Nipple end Flange | ||||||||||||||||||||||||

| 6 | i.e. 1/2″Flange | f | i.e. 1/2″Nipple end Flange | ||||||||||||||||||||||||

| 7 | i.e. 3/4″Flange | g | i.e. 3/4″Nipple end Flange | ||||||||||||||||||||||||

| 8 | i.e. 1″Flange | h | i.e. 1″Nipple end Flange | ||||||||||||||||||||||||

| For Example, SI-P221-N12-S122-L4″-T22 | |||||||||||||||||||||||||||

| SI:e.g. Sampling & Injection Assembly, | |||||||||||||||||||||||||||

| P221: e.g. Solid Plug Body in 316LSS Viton O-Ring and PTFE Primary Packing, | |||||||||||||||||||||||||||

| N12:e.g. injection Nut Connection Size is 1/4″and Material is 316LSS, | |||||||||||||||||||||||||||

| S122:e.g. injection Tube Connection Size is 1/4″ and Material is 316LSS. The type of nozzle is quills | |||||||||||||||||||||||||||

| L4″:For 4″pipe. | |||||||||||||||||||||||||||

| T22: Nipple of Tee Connection Size is 1/2″, Nipple material is 316LSS | |||||||||||||||||||||||||||

Parameters

EMT provides many materials for the Hydraulic Chemical Injection Quill’s body. The choices are in the following form. This kind of chemical injection quill has many advantages. The product is lightweight and flexible. Besides, it has a nice injection efficiency. It also has accurate location tracking. The operating temperature is between -20 and 150℃.

In contrast, the design pressure scope is longer than that. The pressure rating is 2500Psi or as flange size. Note: retractable chemical injectors are 2000 Psi.

The mounting types of the product are a 2” flange connection, 2” farewell access fitting, and 1” NPT welded base. We accept all reasonable requirements of our products. Our professional technical and sales teams will meet customer needs.

| Category | Details |

| Product Information | |

| Product Name | EMT Hydraulic Chemical Injection Quill |

| Brand Name | EMT Pigging |

| Condition | New |

| Type | Injection & Sampling System |

| Certification | ISO 9001 |

| Warranty | 1.5 years |

| Place of Origin | Shenyang City, Liaoning Province, China |

| Physical Specifications | |

| Weight (KG) | Five kilos or more |

| Package Size (cm) | 35 x 40 x 60 (according to customer requirement) |

| Gross Weight (Package, kg) | Eight kilos or more |

| Material and Construction | |

| Sealing Material | Fluororubber, Viton(according to customer requirement) |

| Solid Plug Assembly | 316L Stainless Steel/304ss/Inconel |

| Injection Tube | 316L Stainless Steel/304ss/Inconel |

| NPT Nozzle | 316L Stainless Steel/304ss/Inconel |

| Flange Material | ASTM A105N |

| Operational Parameters | |

| Working Temperature (°C) | -20 to 200 Degree Celsius |

| Operation Temperature (°C) | -20 to 150 Degree Celsius |

| Working Pressure (LB) | 150LB, 300LB, 600LB, 900LB, 1500LB |

| Pressure Rating (PSI) | 6000 PSI or as per Flange Size |

| Applications & Industries | |

| Applicable Industries | Building Material Shops, Construction Works, Energy & Mining, Pipeline Pigging, Oil & Gas Pipeline |

| Application | Pipeline Testing |

| Quality and Compliance | |

| Video Outgoing-Inspection | Provided |

| Machinery Test Report | Provided |

| Showroom Location | None |

| Mounting Options | |

| Mounting Types | 2″ Flange, 2″ Flareweld Access Fitting, 1″ Nipple to NPT Ball Valve, and other sizes according to customer needs |

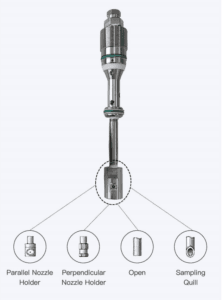

Nozzle Types

Our EMT company provides flange connection type injection quills and welding connection injection quills. Besides, we also provide retractable chemical injectors. There are four types of nozzles in the following form. We produce the product as customer needs.

| Types of Nozzles | |

| 1 | Parallel nozzle |

| 2 | Perpendicular nozzle |

| 3 | Open nozzle |

| 4 | Sampling nozzle |

There are no reviews yet.