1. Introduction:

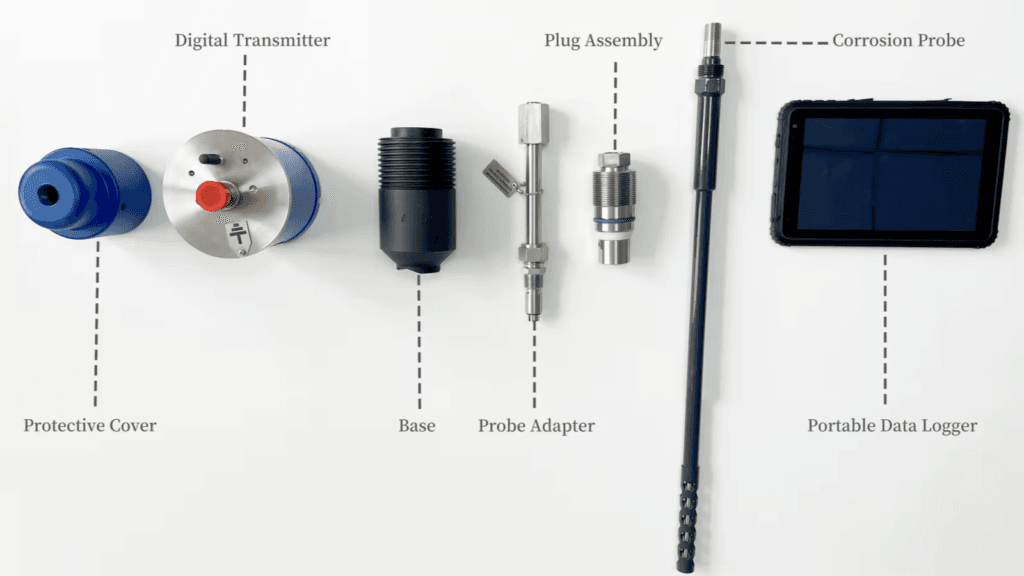

The EMT Erosion Probe is a state-of-the-art monitoring device designed to assess and manage the erosion of materials in industrial settings. Fabricated from high-grade materials like 316 Stainless Steel and Duplex Stainless Steel. This probe offers exceptional resistance to the harsh conditions found in oil and gas production, chemical processing, and other fields where abrasive particles are prevalent in fluids. Equipped with robust sealing components made from Teflon and Fluororubber, the EMT Erosion Probe ensures reliable performance under a wide range of temperatures and pressures. Its advanced design allows for precise placement and efficient erosion detection. Then it makes an essential tool for safeguarding infrastructure and optimizing maintenance regimes.

2. Selection Model

| Model | |||||||||||||||

| ECP | EMT Erosion Probe | ||||||||||||||

| -Code | Plug | ||||||||||||||

|

Pxxx | Type | Material | Sealing material | ||||||||||||

| 0 | Not Required | 0 | Carbon steel | 0 | Not Required | ||||||||||

| 1 | Hollow plug | 1 | 316 stainless steel | 1 | Fluorine rubber sealing ring/PTFE main seal | ||||||||||

| 2 | 316L stainless steel | 2 | HNBR | ||||||||||||

| 3 | F51 duplex stainless steel | ||||||||||||||

| 4 | INCONEL nickel based alloy | ||||||||||||||

| -Code | Temperature and pressure gauge assembly | ||||||||||||||

| Txxx | Connection size | Body material | Temperature and pressure gauge material | ||||||||||||

| 0 | Not Required | 0 | 304 stainless steel | 0 | Not Required | ||||||||||

| 1 | 1/2″ | 1 | 316 stainless steel | 1 | 304 stainless steel | ||||||||||

| 2 | 3/4″ | 2 | 316L stainless steel | 2 | 316 stainless steel | ||||||||||

| 3 | F51 duplex stainless steel | ||||||||||||||

| -Code | Probe assembly | ||||||||||||||

| Dxx ‐Lx″ | Connection size | Body material | Pipeline specification (x ″) | ||||||||||||

| 0 | Not Required | 0 | Carbon steel | Probe length varies with pipeline specifications | |||||||||||

| 1 | 1/4″ | 1 | 304 stainless steel | ||||||||||||

| 2 | 1/2″ | 2 | 304L stainless steel | ||||||||||||

| 3 | 316 stainless steel | ||||||||||||||

| 4 | 316L stainless steel | ||||||||||||||

| 5 | F51 duplex stainless steel | ||||||||||||||

3. Construction and Material Details

Metal Materials:

- 316 Stainless Steel and Duplex Stainless Steel (DUPLEX SS): These materials are selected for their superior erosion resistance and mechanical properties, Crucial in environments where particulate matter in fluids can cause wear and tear on equipment surfaces. Stainless steel 316 provides robust resistance against various erosive and corrosive conditions, ensuring the longevity and reliability of the probe.

Sealing Materials:

- Teflon and Fluororubber: Employed for their excellent resilience against erosive particles and temperature variations. These materials maintain the integrity of the probe’s sealing system even under abrasive conditions.

4. Features and Specifications

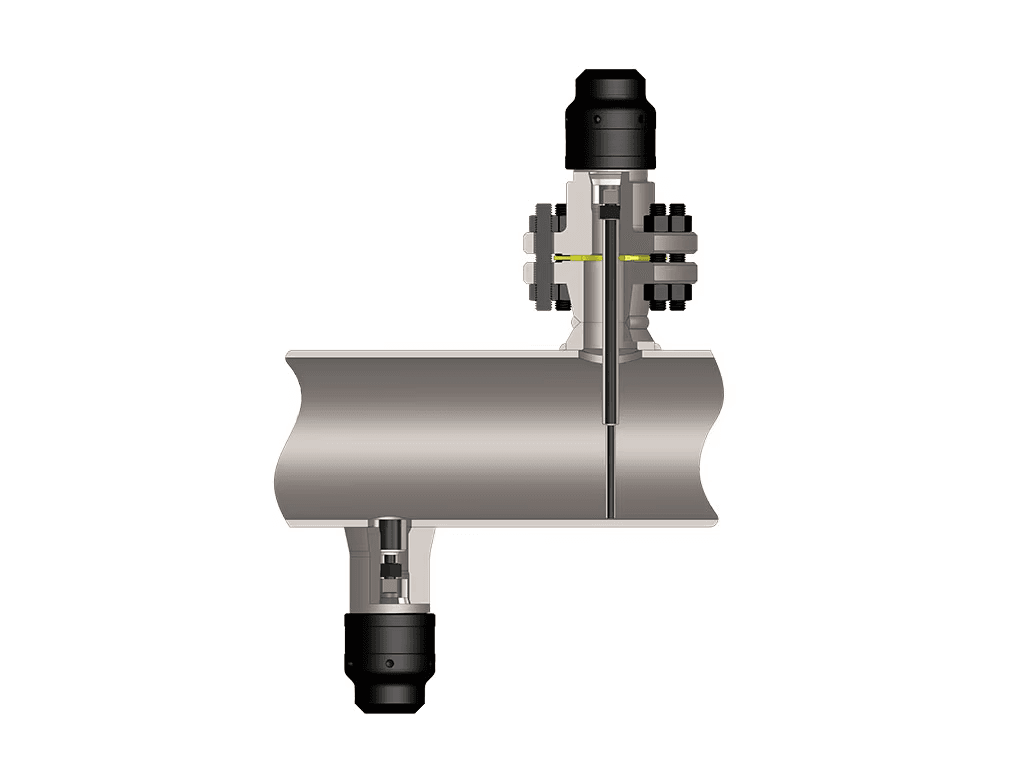

Access Fitting Body and Protective Cover:

- Materials: The use of Carbon Steel (CS), 316L, and DUPLEX SS in the access fitting body and protective cover provides a well-balanced approach to tackling both corrosion and erosion in harsh environments.

- Flange Size: Standardized at ANSI 2″ RF (or RJ), enabling straightforward integration into existing pipeline systems.

- Working Conditions: Designed to withstand temperatures from -20°C to 200°C and pressures up to 26 MPa. The probe is built to perform reliably in extreme conditions.

5. Advantages

Lightweight and Flexible: The probe’s design focuses on minimal weight to facilitate easy handling and installation, without sacrificing durability or performance.

High Injection Efficiency: Engineered to maximize contact with the erosive medium, the probe accurately measures erosion rates by ensuring optimal exposure of the sensor area to the flowing particles.

Accurate Location Tracking: Precision engineering allows for the strategic placement of the probe. Where erosion is most likely to occur, ensuring effective monitoring and protection of critical areas.

6. Applications and Utility of the EMT-CP Erosion Probe

Oil and Gas Industry

In the oil and gas sector, the integrity of infrastructure is paramount due to the high-pressure environments and the corrosive nature of the materials handled. The EMT-CP Corrosion Probe serves a critical role in monitoring the condition of pipelines and storage vessels that are susceptible to hydrogen-induced cracking and embrittlement. This proactive monitoring allows operators to schedule maintenance and replacements based on actual material condition rather than on time-based estimates, thereby optimizing operational efficiency and safety.

Chemical Processing Plants

Chemical plants frequently deal with reactive substances and extreme conditions that can degrade equipment materials. The EMT-CP Corrosion Probe helps in the early detection of material degradation in reactors, transfer pipes, and storage tanks. Its high accuracy and reliability ensure that even the slightest permeation of hydrogen into metal structures is detected, allowing plant managers to mitigate risks associated with unexpected failures and maintain continuous and safe plant operations.

High-Pressure Hydrogen Applications

With the increasing focus on clean energy, hydrogen is being widely adopted as a fuel and energy carrier. However, hydrogen’s small molecule size and high diffusivity increase the risk of metal embrittlement. The EMT-CP Corrosion Probe is essential in applications like hydrogen refueling stations and hydrogen storage systems. Where it can continuously assess the integrity of the system under varying pressures and temperatures, ensuring long-term durability and safety.

General Infrastructure

Beyond the specific industries, any infrastructure involving high-pressure hydrogen or corrosive environments can benefit from the installation of the EMT-CP Corrosion Probe. This includes transportation pipelines, high-pressure vessels, and nuclear power plants where safety and operational integrity are critical. The probe’s capabilities enable a deeper understanding of material behavior under real-world conditions, facilitating better-informed engineering decisions and infrastructure designs.

There are no reviews yet.