Introduction

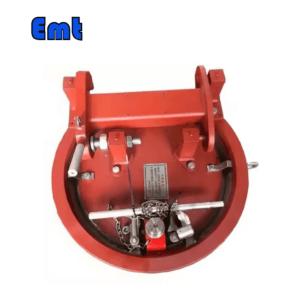

A Pressure Vessel Quick Opening Closure is a device that allows fast and secure access to pressure vessels. Engineers design these closures to ensure rapid opening and closing operations, enhancing productivity. They are crucial for tasks requiring frequent access inside vessels, such as cleaning or inspection. Additionally, these closures maintain a tight seal to prevent leaks and withstand high pressures. Their robust construction ensures safety and reliability in harsh operational environments.

Pressure Vessel Quick Opening Closures offer several advantages in industrial applications. Firstly, they significantly reduce downtime by enabling rapid access for maintenance and inspection. This efficiency boosts productivity and reduces operational costs. Furthermore, their robust sealing mechanisms enhance safety by preventing leaks under high pressure. They also improve compliance with safety regulations, minimizing the risk of accidents. Additionally, these closures are versatile, fitting a variety of vessel types and sizes. Overall, their integration into pressure systems represents a reliable solution that combines safety, efficiency, and operational flexibility.

Pressure Vessel Quick Opening Closure Types

| Lock Ring Type | Band Type | Plug Buckle Type | |

| Installation | Vertical/Horizontal | Vertical/Horizontal | Vertical |

| Size | DN 200 to DN 1200 | DN 150 to DN 1000 | DN 150 to DN 1000 |

| Pressure | ASME #150 to #1500 | ASME #150 & #300 | ASME #150 to #600 |

| Materials | SA 350 LF2 | SA 350 LF2 | SA 516 70N/SA 105N |

| Sealing | Viton™ | Viton™ | Viton™ |

Processing Requirement

1. When processing the main pressure element of the quick-opening closure from a free forging blank, the machining allowance and tolerance of the blank must comply with the provisions of GB/T21469. When processing the blank forging by die forging, the dimensional tolerance and form and position tolerance of the blank must meet the relevant requirements of GB/T12362. Workers must not perform repair welding on free forging and die forging forgings.

2. The surface roughness of the sealing surface of the quick-opening closure head cover and the cylinder flange after machining should not be higher than 1.6. For the mating surface between the rest of the components, the roughness Ra after machining should not be higher than 3.2.

3. Rubber seals for quick-opening closures should be molded as a whole.

4. The finishing of the rotating mating surface of the quick-opening closure, the head cover, and the sealing surface of the cylinder flange should be carried out after heat treatment.

5. Teeth insert type quick opening closure head cover and hook ring teeth slot, clamp type quick opening closure clamp split cutting should be cold cutting.

6. The clamp quick-opening closure head cover and the hook ring should be closed when they mesh. And the contact point of the corresponding surface should not be less than 4 points /cm2~5 points /cm2. There are corresponding teeth that do not coincide with the part and should not be greater than 10mm.

7. Steel plate production parts shall not have rust, the periphery should be machined, and the edges should be blunt.

8. The welding groove should be machined, and the groove type and size should meet the requirements of the design document.

Opening Operation

1.1 Unscrew the upper empty screw by hand. If a ripping sound or oil leakage can be heard, there is pressure in the receiving cylinder (or serving cylinder). In this case, the pressure in the cylinder must be relieved first and then the empty screw must be removed. Drain screws cannot be used as internal pressure relief ports.

1.2 When the pressure in the cylinder is completely discharged, then screw the screw by hand until the screw is completely pulled out, and the safety plug is also pulled out. The safety plug and the hinge are connected with a small chain to avoid loss.

1.3 Loosen the splint screw by twisting the two operating handwheels with both hands, and gradually increase the two ends of the screw until the nut support contacts the tail bolt.

1.4 Pull the handle rod.

1.5 Open the quick opening closure door.

Closing Operations

2.1 Clean the seal ring very carefully and lubricate it with a light oil of the engine oil type. Using oils that are too thick can lead to leaks at low pressure.

2.2 Clean and lubricate the surface of the washer with oil, clean and lubricate the sealing groove with oil, and install the sealing ring, and the position should be correct. The sealing washer shall be 100% in contact with the two faces of the sealing groove. The anti-extrusion spring shall be installed behind the washer, and the spring shall be 100% in place around the circumference of the washer.

2.3 Lubricate the screw carefully with grease.

2.4 Close the door.

2.5 Rotate the handwheel and gradually tighten the double-ended screw.

2.6 When the two nut brackets touch, stop screwing the screw. Do not screw the screw with a wrench.

2.7 Grease the vent screws and screw holes with butter, but do not block the vent.

2.8 Resetting the security lock block.

2.9 Resetting the handle.

There are no reviews yet.