Advantages of the EMT Pig Signaller with a Ball Valve

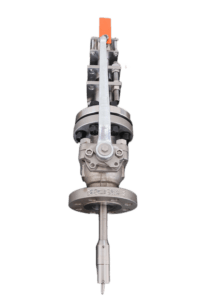

The EMT Pig Signaller with a Ball Valve offers several distinct advantages over other types of Pig Signallers. Firstly, its integrated ball valve design streamlines the setup, reducing the number of components needed. This integration not only saves space but also simplifies the installation process.

Additionally, the EMT model provides quick and easy operation. Operators can swiftly respond to pig detection and simultaneously manage flow control, which enhances both safety and efficiency. This dual functionality ensures that the flow can be stopped or allowed instantly, which is crucial during maintenance or in emergencies.

Moreover, this signaller’s robust construction allows for reliable use in harsh pipeline environments. Its durability leads to longer service life and fewer replacements. Transitioning to maintenance, the EMT Pig Signaller with a Ball Valve requires less upkeep compared to others, thanks to its high-quality materials and design.

Overall, these features make the EMT Pig Signaller with a Ball Valve a cost-effective and reliable choice for companies looking to optimize their pipeline operations.

Parameters

| Name | Pig Signaller With A Ball Valve |

| Connection | Flange Connection |

| Plug body length | 200mm |

| Operating temperature | -20~120℃/Meet customer requirements |

| NACE MR 01- 75 | Yes |

| Ingress protection | IP65/IP66 |

| Explosion-proof class | ExdⅡ BT4 |

| Remove under pressure | Yes |

| Trigger type | Bi-directional/Uni-directional |

| Adjustable length | 0 |

| Internal part material | 316SS/DSS/INCONEL |

| Insert depth | 21mm(Bi)/13mm(Uni) |

| Flange/Body material | PTFE coated A105N/304SS/316SS/DSS/INCONEL(As per MR) |

Key Features of Pig Signaller with a Ball Valve

The integrated design of the EMT pig signaller with a ball valve combines pig detection and flow control into one robust unit. This dual functionality streamlines setup, eliminating the need for additional space and complex fittings. The compact configuration integrates these essential functions seamlessly.

Equipped with advanced sensors, the device reliably detects the passage of a pig at designated points along the pipeline. It often includes both mechanical indicators and electronic alerts. These features provide operators with immediate feedback on the pig’s location, enhancing monitoring precision.

The ball valve component of the signaller allows for quick and secure pipeline shut-off. This capability is critical for safe maintenance and inspection operations. The system’s versatility makes it suitable for various fluids and adaptable to different pipeline pressures and environments.

Safety and operational efficiency are at the forefront of this device’s benefits. It allows operators to detect pigs and control flow remotely, minimizing the need for manual intervention and promoting a safer work environment. This functionality also reduces downtime, as operators can swiftly respond to pig detection and adjust flow, maintaining throughput efficiency.

Installation and maintenance of the EMT pig signaller with a ball valve are straightforward. Its user-friendly interface ensures easy integration into existing pipeline systems without the need for extensive modifications. Built to endure harsh pipeline conditions, the ball valve and signaller require minimal upkeep, further simplifying maintenance tasks.

Applications

EMT Pig Signaller With A Ball Valve works in various industries including oil and gas, chemical processing, and water treatment. They are particularly valuable in systems where precise product flow control and regular pipeline cleaning or inspection are critical to maintaining system integrity and efficiency.

The integration of a pig signaller with a ball valve in a single unit provides a highly effective tool for pipeline management. This setup not only enhances functionality by combining flow control with pig detection but also improves safety, reduces installation complexity, and minimizes maintenance requirements. It is an invaluable addition to any pipeline operation looking to optimize its maintenance processes and ensure continuous, safe operation.

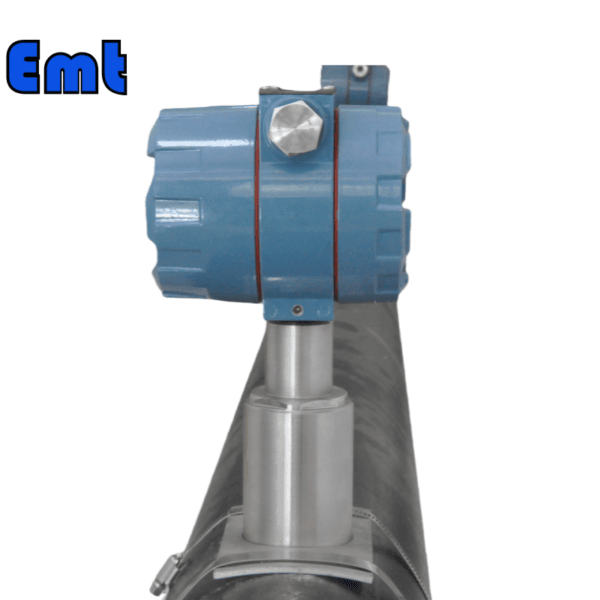

Introduction to the Ball Valve

A ball valve features a spherical disc to control the flow within a pipeline. When the valve closes, the disc, positioned within the valve body, blocks the passageway and stops the flow. Conversely, when the valve opens, the disc aligns perfectly with the pipeline, allowing materials to pass through. This simple mechanism ensures quick and reliable operation.

Moreover, the design of the ball valve offers durability and excellent sealing capabilities, making it ideal for high-pressure applications. Most ball valves also provide ease of operation and maintenance, which ensures long-term reliability and performance. Transitioning smoothly, these features make the ball valve a popular choice across various industries, from oil and gas to pharmaceuticals, where tight shut-off is crucial.

The ball valve is celebrated for its versatility and efficiency, which make it an indispensable component in various industrial applications. Its ability to regulate flow with minimal pressure drop is particularly valuable in systems requiring precise control. The simplicity of its design — featuring few moving parts — minimizes the risk of malfunction, which is a critical advantage in industrial operations where dependability is paramount. Additionally, ball valves can handle not only liquids but also gases and slurries, broadening their applicability across sectors. The quick operation of the valve, from fully open to fully closed with a 90-degree turn of the handle or actuator, allows for rapid isolation of sections of a system, enhancing both safety and convenience. This functionality, combined with its compact size, makes the ball valve a preferred choice for system designers and engineers seeking efficient, reliable flow control solutions.

There are no reviews yet.