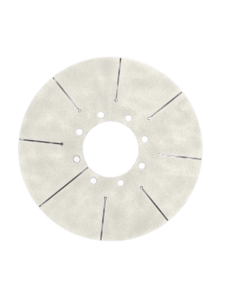

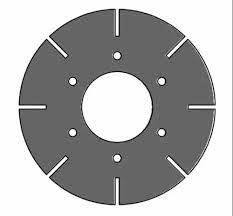

Introduction to EMT Gauging Plate

The EMT Gauging Plate is a vital instrument used in the assessment of pipe deformations with precision. These tools offer accurate measurements crucial for evaluating the integrity of pipelines. The tools enable engineers to make informed decisions about maintenance and repairs. By utilizing gauging plates, professionals can effectively monitor and analyze any structural changes in pipelines. It ensures the safety and efficiency of the infrastructure.

The functionality of gauging plates lies in their ability to detect even minor deviations in pipe dimensions. Through regular inspections using gauging plates, engineers can proactively address deformations or abnormalities. The high sensitivity of these plates allows for early detection of anomalies. It helps maintain the structural integrity of pipelines and prevents catastrophic failures.

Engineered for precision, gauging plates play a critical role in the maintenance and monitoring of pipelines across various industries. With their capability to provide accurate and reliable data on pipe conditions, gauging plates serve as indispensable tools in ensuring the continued functionality and safety of vital infrastructure networks. By incorporating gauging plates into routine maintenance practices, organizations can uphold operational efficiency and minimize risks associated with pipeline deformations.

Features and Advantages of Gauging Plates

Gauging plates offer a range of features that make them indispensable tools in pipeline maintenance. These plates are designed with precision measurement capabilities, allowing for accurate assessment of pipe deformations and irregularities. Their robust construction ensures durability and longevity, providing reliable performance in demanding industrial environments. Gauging plates are versatile instruments that can be used across various pipe sizes and materials. They enhance their usability across different pipeline systems. Additionally, their user-friendly design and ease of operation make them accessible to engineers and technicians, facilitating efficient and effective pipeline inspections.

The advantages of using gauging plates are manifold. By enabling precise measurements, gauging plates aid in the early detection of potential issues. Besides it helps prevent costly damages and failures in pipelines. Their high sensitivity allows for proactive maintenance strategies, ensuring timely interventions to address deformations and maintain pipeline integrity. Furthermore, the data obtained from gauging plates supports informed decision-making in pipeline maintenance, guiding engineers in implementing targeted repairs and maintenance activities. Overall, the features and advantages of gauging plates contribute to enhanced safety, efficiency, and longevity of pipeline systems in various industrial settings.

Purpose of Using Gauging Plate

The primary purpose of using gauging plate is to accurately measure and assess deformations in pipelines. By placing gauging plates strategically along a pipeline, engineers can obtain precise measurements of any changes in the pipe’s dimensions, such as ovality or bulging. This data is essential for evaluating the structural integrity of the pipeline and identifying potential issues that could lead to leaks or failures. Gauging plates play a crucial role in preventive maintenance by enabling early detection of deformations, allowing for proactive measures to be taken before problems escalate, reducing the risk of costly repairs and downtime.

Another key purpose of gauging plates is to monitor the condition of pipelines over time. By regularly using gauging plates to measure and track changes in pipe dimensions, engineers can assess the rate of deformation and structural deterioration. This monitoring helps in determining the overall health of the pipeline, guiding maintenance schedules and repair priorities. Gauging plates provide valuable data that supports informed decision-making regarding pipeline maintenance, ensuring that necessary actions are taken to preserve the integrity and reliability of the infrastructure.

Applications of Piping Pigs with Gauging Plates

The combination of piping pigs with gauging plates offers a comprehensive solution for pipeline maintenance and inspection. Piping pigs, which are devices inserted into pipelines for cleaning and inspection purposes, can be enhanced with the addition of gauging plates. By integrating gauging plates into the design of piping pigs, operators can not only clean the pipeline but also simultaneously gather precise measurements of the pipe’s internal dimensions. This integrated approach allows for efficient cleaning operations while obtaining accurate data on deformations or irregularities within the pipeline. It facilitates a more thorough assessment of the pipeline’s condition.

The application of piping pigs with gauging plates is particularly beneficial in industries where pipeline integrity is critical, such as oil and gas, chemical processing, and water treatment. This combined technology enables operators to conduct routine maintenance tasks efficiently while simultaneously monitoring the structural health of the pipeline. By using piping pigs equipped with gauging plates, operators can proactively identify issues such as corrosion, ovality, or blockages, enabling timely interventions to prevent potential failures and ensure the continued reliability of the pipeline system. This integrated approach enhances the overall efficiency and effectiveness of pipeline maintenance activities. Besides it ultimately contributing to improved operational safety and performance.

There are no reviews yet.