Introduction

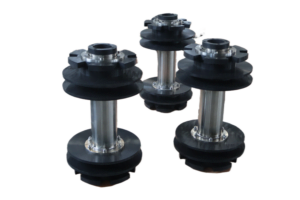

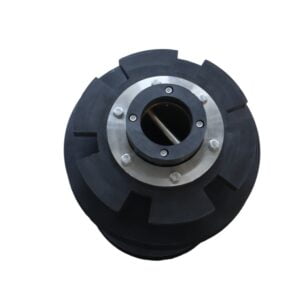

EMT Fluororubber Pigs stand out in the pipeline maintenance industry due to their superior resistance to high temperatures and strong corrosion, coupled with exceptional cleanliness capabilities. Unlike traditional polyurethane pigs, EMT Fluororubber Pigs are particularly effective in handling challenging conditions, such as the presence of wax within pipelines, which is often difficult to clean. These pigs facilitate the enhancement of oil and gas flow within pipelines, significantly improving the cleanliness and quality of the pipeline system. Their robust composition makes them especially suitable for use in environments with high ambient temperatures or severe corrosivity, effectively extending the service life of the pipeline system. Available in a standard size of 2-in, EMT also offers customization options to cater to various pipeline sizes and specific client needs, ensuring versatile and efficient pipeline maintenance solutions.

Specifications

Fluororubber, also known as fluororubber FKM, is a synthetic rubber with excellent high-temperature resistance, chemical medium resistance, and oil resistance. Commonly used in aviation, automotive, chemical, and other fields, also known as high-performance rubber.

| Performance indicator | Parameter value density |

| density | 1.80-1.90 g/cm³ |

| hardness | 60-90 Shore A |

| Tensile strength | 10-22 MPa |

| Elongation at break | 120-300% |

| Heat resistance | -30℃ to +250℃ |

| Chemical resistance | Resistant to acid, alkali, oxidation, and petroleum products |

Performance parameter interpretation

1. Density: The density of perfluoro rubber is relatively large, mainly affected by the material formula, generally between 1.80-1.90g /cm³.

2. Hardness: Hardness is an indicator of the hardness of rubber materials, perfluorinated rubber hardness between 60-90 Shore A, the greater the hardness value, the higher the hardness of the material.

3. Tensile strength: The tensile strength of perfluorinated rubber, that is, the ability to resist damage when it is stretched by external forces, is usually between 10-22 MPa, and has good tensile resistance.

4. Fracture elongation: The fracture elongation of perfluorinated rubber refers to the ratio of the material to your length and the original length when it is stretched under external force, usually between 120-300%, with strong toughness.

5. Heat resistance: perfluorinated rubber has excellent high temperature resistance, usually the temperature range is -30℃ to +250℃, can adapt to high temperature working environment, with excellent heat resistance.

6. Chemical resistance: Perfluorinated rubber shows good chemical resistance in the chemical environment, with acid resistance, alkali resistance, oxidation resistance, oil products and other characteristics.

Pig Parameters

The material properties of fluororubber, which is the primary component of EMT Fluororubber Pigs, contribute significantly to their high performance. Fluororubber is a synthetic polymer elastomer that includes fluorine atoms attached to the carbon atoms of its main or side chains. This structural characteristic imparts outstanding properties to the rubber, such as heat resistance, oxidation resistance, oil resistance, corrosion resistance, and resistance to atmospheric aging. Since its development in 1943, fluororubber has been used extensively across various high-demand sectors, including aerospace, aviation, automotive, petroleum, and household appliances. Its critical role in these industries underscores the material’s reliability and the advanced capabilities it brings to applications like pipeline maintenance, where durability and performance under extreme conditions are paramount.

| Name | EMT Fluororubber Pigs |

| Material | 1. steel framework main body. |

| 2. The disc material used to be Polyurethane, Viton, Neoprene, Nitrile butadiene, etc. | |

| 3. The cup material used to be Polyurethane, Viton, Neoprene, Nitrile butadiene, etc. | |

| 4. Steel brush or nylon brush. | |

| Features | 1. Firstly, good wearing resistance. |

| 2. Secondly, strong passing ability. | |

| 3. Nice cleaning performance. | |

| 4. Then accurate location and tracking. | |

| 5. At last, a low rate of false positives. | |

| Packing way | packed pipe cleaning pigs with inner plastic film and outer plywood wooden case. |

| Payment | TT/LC |

| Advantages | 1. Firstly, good sealing performance. |

| 2. Secondly, high wear resistance. |

Fluororubber Applications

1. Aerospace

Fluorine rubber is widely used in the aerospace field, such as aircraft and rocket seals, cable protection tubes, oxygen system and fuel system seals, spacecraft insulation materials and other aspects. Fluorine rubber has been widely used in spacecraft because of its excellent high-temperature resistance and stable operation in high-temperature environments.

2. Automobile manufacturing

Fluorine rubber is also widely used in the automotive industry, such as engine oil seals, automotive pipeline seals, oil-resistant pipelines and so on. Because automotive parts need to have good oil and corrosion resistance, fluoro rubbers become the ideal material for manufacturing these parts.

3. Chemical Industry

In the chemical industry, fluorine rubber is also widely used, such as corrosion-resistant pump impellers and seals, valve seals, chemical equipment seals, and other aspects. By using fluorine rubber to manufacture these parts, the corrosion resistance of the equipment can be greatly improved and the service life of the equipment can be extended.

Our Service

EMT Company proudly offers Fluororubber Pigs for superior pipeline maintenance. These pigs excel in extreme conditions, ensuring optimal cleanliness and flow in oil and gas pipelines. Their unique composition withstands high temperatures and aggressive chemicals, making them ideal for demanding environments. EMT provides customizable sizes to fit various pipeline specifications, enhancing both efficiency and reliability. Each pig features robust construction that significantly extends pipeline service life.

There are no reviews yet.