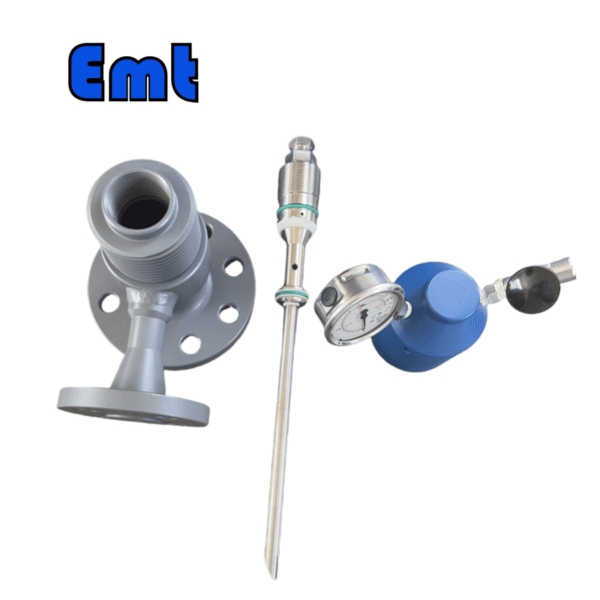

Advantages of EMT Flanged Injection Quill

EMT Flanged injection quills offer several advantages over their welded counterparts. One significant benefit is the ease of installation and removal. Flanged connections allow for quicker and safer attachment or detachment from the pipeline compared to welded connections, which require cutting and welding. This feature not only saves time during maintenance but also reduces downtime in operations.

Another advantage of flanged injection quills is their superior adaptability and flexibility. You can easily replace or upgrade them owing to the standardized flange fittings, which are not as straightforward with welded quills. This makes flanged quills more suitable for systems that undergo frequent configuration changes or require regular maintenance.

Lastly, flanged injection quills provide better safety and leak prevention. The bolted connection of flanges creates a more secure seal, reducing the likelihood of leaks compared to welded joints, which can suffer from fatigue and cracks over time. This reliability is crucial in high-pressure applications where safety and environmental considerations are paramount.

Specifications of Flanged Injection Quill

| Category | Details |

| Product Information | |

| Product Name | Chemical Injection Quill |

| Brand Name | EMT Pigging |

| Condition | New |

| Type | Injection & Sampling System |

| Certification | ISO 9001 |

| Warranty | 1.5 years |

| Place of Origin | Liaoning, China |

| Physical Specifications | |

| Weight (KG) | 5 |

| Package Size (cm) | 35 x 40 x 60 |

| Gross Weight (Package, kg) | 8 |

| Material and Construction | |

| Sealing Material | Fluororubber |

| Solid Plug Assembly | 316L Stainless Steel |

| Injection Tube | 316L Stainless Steel |

| NPT Nozzle | 316L Stainless Steel |

| Flange Material | ASTM A105N |

| Operational Parameters | |

| Working Temperature (°C) | -20 to 200 |

| Operation Temperature (°C) | -20 to 150 |

| Working Pressure (LB) | 150LB, 300LB, 600LB, 900LB, 1500LB |

| Pressure Rating (PSI) | 6000 PSI or as per Flange Size |

Applications

Flanged injection quills play a crucial role in various industries, primarily due to their precision in injecting chemicals. In water treatment, they precisely dose chemicals like chlorine and coagulants. This uniform distribution enhances treatment effectiveness.

In the oil and gas sector, these quills inject protectants such as corrosion inhibitors and biocides into pipelines. This protection extends pipeline life and ensures operational safety. Similarly, chemical processing plants rely on flanged injection quills for the accurate addition of catalysts. Precise dosing maintains desired reactions and product quality.

Additionally, power generation facilities use these quills to inject chemicals into boiler feed water. This prevents scaling and corrosion, crucial for boiler efficiency and longevity. In the food and beverage industry, quills inject sanitizers into product lines, ensuring compliance with health regulations and food safety.

Overall, the versatility and precision of flanged injection quills make them indispensable in industries where chemical dosing is essential for quality and safety.

EMT Chemical Injection Quill Selection Model

| Model | |||||||||||||||||||||||||||

| SI | Chemical Injector Quill | ||||||||||||||||||||||||||

| -Code | Plug | ||||||||||||||||||||||||||

| Pxxx | Type | Material | Sealing Material | ||||||||||||||||||||||||

| 0 | No Request | 0 | CS | 0 | No Request | ||||||||||||||||||||||

| 1 | Hollow Plug Body | 1 | 316SS | 3 | DSS | 1 | Viton O-Ring / PTFE Primary Packing | ||||||||||||||||||||

| 2 | Solid Plug Body | 2 | 316LSS | 4 | INCONEL | 2 | HNBR | ||||||||||||||||||||

| – Code | Injection Nut | ||||||||||||||||||||||||||

| Nxx | Connection Size | Material | |||||||||||||||||||||||||

| 0 | i.e. No Request | 0 | i.e. CS | ||||||||||||||||||||||||

| 1 | i.e. 1/4″ | 1 | i.e. 316SS | 3 | i.e. DSS | ||||||||||||||||||||||

| 2 | i.e. 1/2″ | 2 | i.e. 316LSS | 4 | i.e. INCONEL | ||||||||||||||||||||||

| – Code | Injection Tube | ||||||||||||||||||||||||||

| Sxxx-Lx″ | Connection Size | Material | Nozzle | Line size(x″) | |||||||||||||||||||||||

| 0 | No Request | 0 | CS | 0 | i.e. No Request | The most effective position for injection is generally at the center of the pipe | |||||||||||||||||||||

| 1 | i.e. 1/4″ | 1 | i.e. 316SS | 1 | i.e. Open | ||||||||||||||||||||||

| 2 | i.e. 1/2″ | 2 | i.e. 316LSS | 2 | i.e. Quill | ||||||||||||||||||||||

| 3 | i.e. DSS | 3 | i.e. Cap & Core | ||||||||||||||||||||||||

| 4 | i.e. INCONEL | ||||||||||||||||||||||||||

| – Code | Nipple and Valve(or end Flange)of Tee | ||||||||||||||||||||||||||

| Txx | Connection Size | Material | |||||||||||||||||||||||||

| 0 | i.e. No Request | 0 | i.e. CS | ||||||||||||||||||||||||

| 1 | i.e. 1/4″Nipple | a | i.e. 1/4″Nipple and Valve | 1 | i.e. 316SS | ||||||||||||||||||||||

| 2 | i.e. 1/2″Nipple | b | i.e. 1/2″Nipple and Valve | 2 | i.e. 316LSS | ||||||||||||||||||||||

| 3 | i.e. 3/4″Nipple | c | i.e. 3/4″Nipple and Valve | 3 | i.e. D SS | ||||||||||||||||||||||

| 4 | i.e. 1″Nipple | d | i.e. 1″Nipple and Valve | 4 | i.e. INCONEL | ||||||||||||||||||||||

| 5 | i.e. 1/4″Flange | e | i.e. 1/4″Nipple end Flange | ||||||||||||||||||||||||

| 6 | i.e. 1/2″Flange | f | i.e. 1/2″Nipple end Flange | ||||||||||||||||||||||||

| 7 | i.e. 3/4″Flange | g | i.e. 3/4″Nipple end Flange | ||||||||||||||||||||||||

| 8 | i.e. 1″Flange | h | i.e. 1″Nipple end Flange | ||||||||||||||||||||||||

| For Example, SI-P221-N12-S122-L4″-T22 | |||||||||||||||||||||||||||

| SI:e.g. Sampling & Injection Assembly, | |||||||||||||||||||||||||||

| P221: e.g. Solid Plug Body in 316LSS Viton O-Ring and PTFE Primary Packing, | |||||||||||||||||||||||||||

| N12:e.g. injection Nut Connection Size is 1/4″and Material is 316LSS, | |||||||||||||||||||||||||||

| S122:e.g. injection Tube Connection Size is 1/4″ and Material is 316LSS. The type of nozzle is quills | |||||||||||||||||||||||||||

| L4″:For 4″pipe. | |||||||||||||||||||||||||||

| T22: Nipple of Tee Connection Size is 1/2″, Nipple material is 316LSS | |||||||||||||||||||||||||||

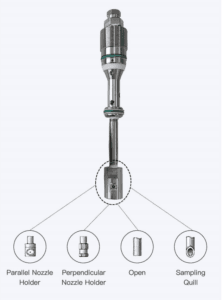

Type of Nozzles

Nozzles are essential components in various industrial applications, each designed to meet specific operational requirements. Let’s explore four common types:

First, the Parallel nozzle directs fluid flow parallel to the attaching surface. This design is ideal for applications requiring a streamlined flow along the surface it is mounted on. Next, the Perpendicular nozzle, in contrast, directs fluid at a right angle to the attaching surface. This type is often used in cooling and spraying applications where direct impact is needed.

Moving on, the Open nozzle is characterized by its lack of a valve or closure mechanism. It continuously allows fluid flow, making it suitable for constant drainage or overflow systems. Finally, the Sampling nozzle serves a specific purpose. It facilitates the extraction of fluid samples from tanks or pipelines for analysis. This type is crucial for quality control and ensuring compliance with industry standards.

Each nozzle type offers unique benefits, tailored to meet diverse industrial needs, enhancing both efficiency and functionality.

| Types of Nozzles | |

| 1 | Parallel nozzle |

| 2 | Perpendicular nozzle |

| 3 | Open nozzle |

| 4 | Sampling nozzle |

There are no reviews yet.