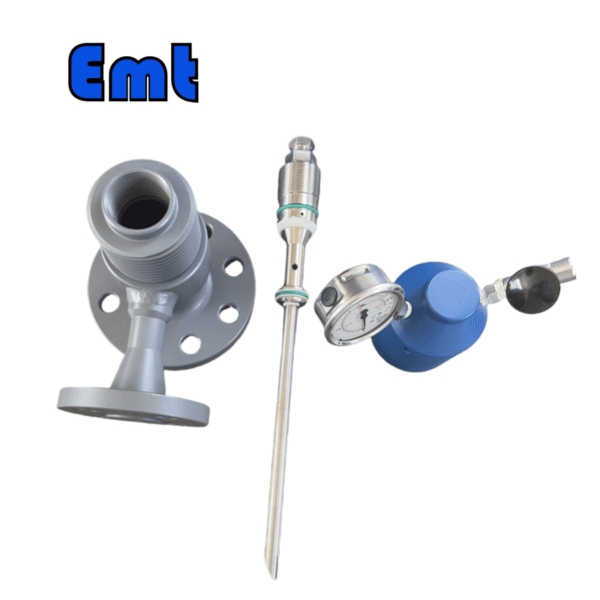

EMT Flanged Connection Injection Quill

The EMT Flanged Connection Injection Quill is a specialized device designed for precise injection of fluids into pipelines. Constructed with durable materials, it features a robust flanged connection that ensures secure and leak-free installation on various pipeline systems.

This injection quill allows for easy integration into existing piping networks, facilitating the injection of chemicals, additives, or other fluids directly into the flow. Its design includes strategically placed injection ports that optimize mixing and distribution within the pipeline, ensuring efficient treatment processes.

Additionally, the EMT Flanged Connection Injection Quill is engineered for versatility, accommodating different fluid viscosities and flow rates. The device is suitable for use in a range of industries, including oil and gas, water treatment, and chemical processing. By utilizing this injection quill, operators can enhance their pipeline operations, improve fluid management, and ensure compliance with safety and environmental standards.

Selection Model

| Model | |||||||||||||||||||||||||||

| SI | Chemical Injector Quill | ||||||||||||||||||||||||||

| -Code | Plug | ||||||||||||||||||||||||||

| Pxxx | Type | Material | Sealing Material | ||||||||||||||||||||||||

| 0 | No Request | 0 | CS | 0 | No Request | ||||||||||||||||||||||

| 1 | Hollow Plug Body | 1 | 316SS | 3 | DSS | 1 | Viton O-Ring / PTFE Primary Packing | ||||||||||||||||||||

| 2 | Solid Plug Body | 2 | 316LSS | 4 | INCONEL | 2 | HNBR | ||||||||||||||||||||

| – Code | Injection Nut | ||||||||||||||||||||||||||

| Nxx | Connection Size | Material | |||||||||||||||||||||||||

| 0 | i.e. No Request | 0 | i.e. CS | ||||||||||||||||||||||||

| 1 | i.e. 1/4″ | 1 | i.e. 316SS | 3 | i.e. DSS | ||||||||||||||||||||||

| 2 | i.e. 1/2″ | 2 | i.e. 316LSS | 4 | i.e. INCONEL | ||||||||||||||||||||||

| – Code | Injection Tube | ||||||||||||||||||||||||||

| Sxxx-Lx″ | Connection Size | Material | Nozzle | Line size(x″) | |||||||||||||||||||||||

| 0 | No Request | 0 | CS | 0 | i.e. No Request | The most effective position for injection is generally at the center of the pipe | |||||||||||||||||||||

| 1 | i.e. 1/4″ | 1 | i.e. 316SS | 1 | i.e. Open | ||||||||||||||||||||||

| 2 | i.e. 1/2″ | 2 | i.e. 316LSS | 2 | i.e. Quill | ||||||||||||||||||||||

| 3 | i.e. DSS | 3 | i.e. Cap & Core | ||||||||||||||||||||||||

| 4 | i.e. INCONEL | ||||||||||||||||||||||||||

| – Code | Nipple and Valve(or end Flange)of Tee | ||||||||||||||||||||||||||

| Txx | Connection Size | Material | |||||||||||||||||||||||||

| 0 | i.e. No Request | 0 | i.e. CS | ||||||||||||||||||||||||

| 1 | i.e. 1/4″Nipple | a | i.e. 1/4″Nipple and Valve | 1 | i.e. 316SS | ||||||||||||||||||||||

| 2 | i.e. 1/2″Nipple | b | i.e. 1/2″Nipple and Valve | 2 | i.e. 316LSS | ||||||||||||||||||||||

| 3 | i.e. 3/4″Nipple | c | i.e. 3/4″Nipple and Valve | 3 | i.e. D SS | ||||||||||||||||||||||

| 4 | i.e. 1″Nipple | d | i.e. 1″Nipple and Valve | 4 | i.e. INCONEL | ||||||||||||||||||||||

| 5 | i.e. 1/4″Flange | e | i.e. 1/4″Nipple end Flange | ||||||||||||||||||||||||

| 6 | i.e. 1/2″Flange | f | i.e. 1/2″Nipple end Flange | ||||||||||||||||||||||||

| 7 | i.e. 3/4″Flange | g | i.e. 3/4″Nipple end Flange | ||||||||||||||||||||||||

| 8 | i.e. 1″Flange | h | i.e. 1″Nipple end Flange | ||||||||||||||||||||||||

| For Example, SI-P221-N12-S122-L4″-T22 | |||||||||||||||||||||||||||

Key Features of EMT Flanged Connection Injection Quill

The EMT Flanged Connection Injection Quill is distinguished by its robust flanged connection, which ensures secure and leak-free installation across various pipeline systems. This feature is crucial for maintaining the integrity of the pipeline and preventing fluid loss during injection processes. The durable construction of the quill, made from high-quality materials, allows it to withstand harsh operating conditions and resist corrosion, thereby ensuring long-lasting performance in demanding environments.

Another significant aspect of the EMT Injection Quill is its optimized injection ports. These strategically positioned ports facilitate efficient mixing and distribution of injected fluids, enhancing the overall effectiveness of treatment processes. This design allows for precise control over the injection process, which is essential for improving fluid management within pipelines. Additionally, the quill accommodates a wide range of fluid viscosities and flow rates, making it versatile and suitable for diverse applications across various industries, including oil and gas, water treatment, and chemical processing.

Installation of the EMT Flanged Connection Injection Quill is straightforward, enabling easy integration into existing piping networks. This feature simplifies the setup process and minimizes disruption to ongoing operations. Furthermore, the quill is designed for maintenance-friendly access, allowing operators to perform routine checks and repairs with ease, thus reducing downtime and operational costs.

Lastly, the injection quill is engineered to comply with industry safety and environmental standards. This design ensures safe operation and minimizes risks associated with fluid injection. Customizable options are also available for various sizes and configurations. These options meet specific project requirements effectively. By incorporating these key features, the EMT Flanged Connection Injection Quill provides a reliable solution for fluid injection. It enhances operational efficiency and reliability in pipeline systems.

Parameters of EMT Injection Quill

| Applications & Industries | |

| Applicable Industries | Building Material Shops, Construction Works, Energy & Mining, Pipeline Pigging, Oil & Gas Pipeline |

| Application | Pipeline Testing |

| Quality and Compliance | |

| Video Outgoing-Inspection | Provided |

| Machinery Test Report | Provided |

| Showroom Location | None |

| Mounting Options | |

| Mounting Types | 2″ Flange, 2″ Flareweld Access Fitting, 1″ Nipple to NPT Ball Valve |

| Category | Details |

| Product Information | |

| Product Name | Chemical Injection Quill |

| Brand Name | EMT Pigging |

| Condition | New |

| Type | Injection & Sampling System |

| Certification | ISO 9001 |

| Warranty | 1.5 years |

| Place of Origin | Liaoning, China |

| Physical Specifications | |

| Weight (KG) | 5 |

| Package Size (cm) | 35 x 40 x 60 |

| Gross Weight (Package, kg) | 8 |

| Material and Construction | |

| Sealing Material | Fluororubber |

| Solid Plug Assembly | 316L Stainless Steel |

| Injection Tube | 316L Stainless Steel |

| NPT Nozzle | 316L Stainless Steel |

| Flange Material | ASTM A105N |

| Operational Parameters | |

| Working Temperature (°C) | -20 to 200 |

| Operation Temperature (°C) | -20 to 150 |

| Working Pressure (LB) | 150LB, 300LB, 600LB, 900LB, 1500LB |

| Pressure Rating (PSI) | 6000 PSI or as per Flange Size |

Applications

Chemical injection quills serve various applications in multiple industries. Operators use them to inject corrosion inhibitors into pipelines. They also add biocides to control bacterial growth in water systems. In oil and gas, quills inject chemicals for enhanced oil recovery. Water treatment facilities utilize them for dosing flocculants and coagulants. Additionally, quills facilitate the injection of scale inhibitors to prevent mineral build-up. Companies rely on these devices to optimize chemical management and improve system efficiency. Overall, chemical injection quills play a vital role in maintaining pipeline integrity and performance.

There are no reviews yet.