Overview and Applications

Criss Cross Foam Pigs are a specialized type of pipeline cleaning pig, specifically designed for light cleaning, drying, and wiping operations in a variety of pipeline systems. Firstly, these pigs are constructed from foam, which can be either coated or impregnated with abrasives or other materials to significantly enhance their cleaning effectiveness. Furthermore, the distinguishing “Criss Cross” pattern generally refers to the external configuration of the pig. This design may incorporate crisscrossing straps or wire brushes, which are crucial as they aid in removing debris and residue more effectively from the pipeline walls. Overall, this strategic design and material choice ensure that Criss Cross Foam Pigs efficiently maintain pipeline cleanliness and functionality.

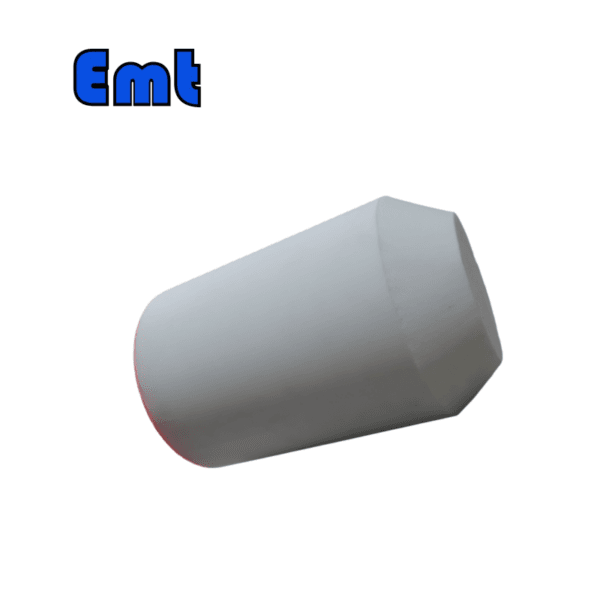

A Criss Cross Foam Cleaning Pig is a type of pipeline cleaning tool specifically designed for maintenance and inspection activities within pipeline systems. It is made from foam, often polyurethane, and features a unique design to enhance its cleaning effectiveness.

Parameters

| Crisscross Foam Pig | LCQZ-RTCC | 1. The interior is foamed by polyurethane material. The surface is covered with a prismatic block polyurethane elastomer. | Operating temperature: -30℃~100℃ |

| 2. High surface hardness and large friction coefficient. | |||

| 3. Has high elasticity and toughness. | |||

| 4. Used for pipeline cleaning, cleaning, and cleaning impurities. | |||

| Crisscross Foam Pig With Brush | LCQZ-RTCB | 1. Polyurethane material foams the interior. An elastomer coating coats the surface. | Starting pressure: 0.02 MPa |

| 2. Paste the spiral wire brush. | Density: 35 kg/m³~220 kg/m³ | ||

| 3. The deformation amount can reach 40%. Which is both elastic and will not fall off. | Withstand pressure: 7 MPa | ||

| 4. It is used to remove the hard scale of the pipeline and has better rust removal and decontamination effects. | Stretch rate: 320% | ||

| Compression ratio: 50 | |||

| Flex life: 50,000 times | |||

| Attrition rate: 2 mm/100 km | |||

| Operating distance: 100 km~300 km | |||

| Operating temperature: -30℃~100℃ |

Key Features of Criss Cross Foam Pigs:

Material Flexibility: Criss Cross Foam Pigs generally consist of open-cell polyurethane foam, which offers excellent flexibility and enables the pig to navigate bends, elbows, and tight pipeline configurations without getting stuck or damaging the pipeline interior.

Versatile Cleaning Capabilities: These pigs can perform a variety of tasks, including light cleaning, drying, or wiping, demonstrating their adaptability. The crisscross pattern on these pigs helps in enhancing the surface contact and abrasiveness, making them particularly effective for removing loose debris and condensation.

Customization Options: Operators can customize these pigs in terms of density, coating, and size to tailor them to specific pipeline conditions and requirements. For instance, manufacturers might use heavier coatings for more abrasive cleaning, while they could choose lighter coatings for general wiping tasks.

Cost-Effective Maintenance Solution: Foam pigs, including those with a Criss Cross design, often provide a more cost-effective solution compared to solid cast pigs or other types of mechanical cleaning pigs.They are disposable, easy to use, and do not require extensive maintenance or replacement parts.

Applications:

Criss Cross Foam Pigs serve a variety of applications in pipeline maintenance and cleaning. Operators use them primarily to enhance the cleaning process, ensuring thorough debris removal. Their design allows them to navigate complex pipeline structures effectively. This makes them ideal for pipelines with bends and diameter changes. Industries often employ these pigs for routine cleaning to maintain flow efficiency. They remove loose scale, rust, and other deposits effectively. After hydrotesting or maintenance, these pigs dry and wipe pipelines, preparing them for operation. They also play a crucial role in batch separation tasks. This helps prevent product contamination in multiproduct pipelines.

The flexibility of Criss Cross Foam Pigs allows for customization in density and coating. Such customization tailors them for specific tasks, from light wiping to more abrasive cleaning. Environmental safety also stands out as a key benefit. These pigs offer a greener alternative to methods involving harsh chemicals. They reduce the environmental impact associated with pipeline cleaning. Overall, Criss Cross Foam Pigs combine functionality, adaptability, and environmental consciousness, making them a preferred choice in diverse pipeline systems.

There are no reviews yet.