The Corrosion Probe Transmitter EMT-CP is a highly robust and efficient monitoring device, specifically engineered to operate seamlessly within high-pressure access systems. This fixed-length, retrievable transmitter is designed to provide accurate measurements of corrosion rates in various industrial environments, particularly where harsh conditions are prevalent.

Access Fitting Body

| Model | ||||||

| EMT-CIPA | Access Fitting Body of Coupon, Injector, Probe assembly | |||||

| – The material of Access Fitting Body | ||||||

| 0 | CS | |||||

| 1 | 316SS | |||||

| 2 | 316LSS | |||||

| 3 | DUPLEX SS | |||||

| The Type of Access Fitting Body | ||||||

| B | 2″Welded(suffix “pressure rating” can be added to B) | |||||

| F | 2″ANSI Flange(suffix “pressure rating & sealing type” can be added to F) | |||||

| -Tee Size- pressure rating & sealing type if flanged end | ||||||

| 0 | No Tee | |||||

| 1 | 1/4″NPT(F)Tee | |||||

| 2 | 1/2″NPT(F)Tee | |||||

| 3 | 3/4″NPT(F)Tee | |||||

| 4 | 1″NPT(F)Tee | |||||

| 5 | Hole for 1/4″SWN Flange | |||||

| 6 | Hole for 1/2″SWN Flange | |||||

| 7 | Hole for 3/4″SWN Flange | |||||

| 8 | Hole for 1″SWN Flange | |||||

| -Protective Cover Type/ Material | ||||||

| 0 | No Protective Cover | Material | ||||

| 1 | Without hole | CS or 0 | ||||

| 2 | With hole | SS or 1 | ||||

| 3 | Bleed Valve | DSS or 3 | ||||

| 4 | Bleed Valve, & Pressure Gauge | |||||

| For Example:EMT-CIPA-0F600#RF-0-2/CS shows 2″ANSI 600#RF Flange Access Fitting Body in CS, no Tee, Protective Cover in CS with hole 0F600#RF: 0F_ Access Fitting Body is Flanged in CS , 600#RF _Size is 2″ANSI 600#RF , 0:No Tee 2: Protective cover with 1/2NPT(F) hole /CS: Protective cove material in CS | ||||||

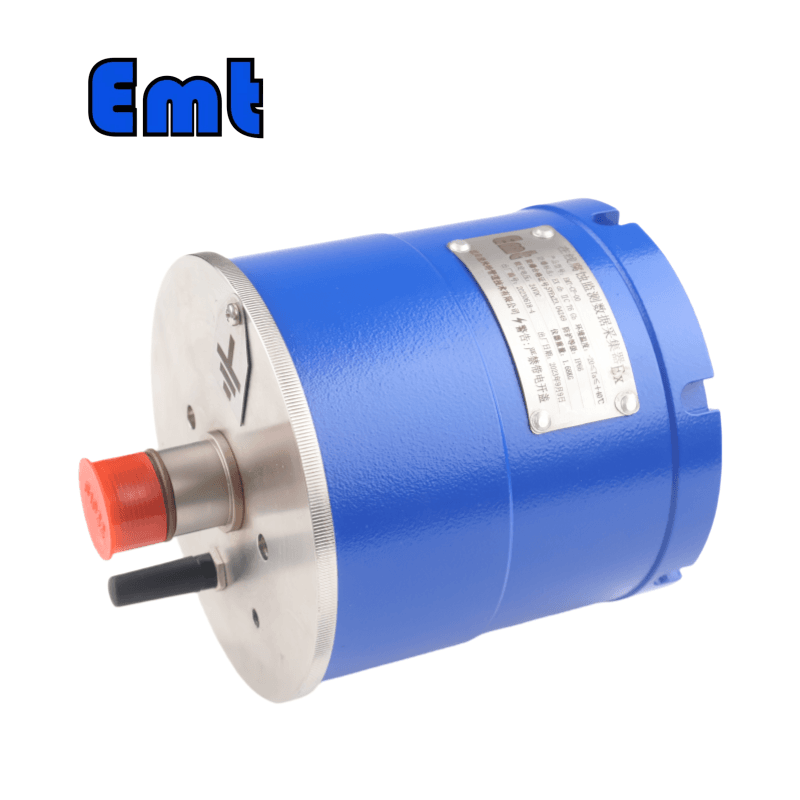

Cylindrical Electrical Resistance Corrosion Probe

| Model | |||||||||||

| EP100 | Corrosion probe transmitter | ||||||||||

| -Code | Body Material | ||||||||||

| -B | 1 | 316 SS | |||||||||

| 2 | 316L SS | ||||||||||

| 3 | DUPLEX SS | ||||||||||

| 4 | INCONEL | ||||||||||

| -Code | Connector Type | ||||||||||

| -C | 1 | Standard connector | |||||||||

| 2 | Meet user requirements connector | ||||||||||

| -Code | ER Element Useful Thickness Options | ||||||||||

| -T | 10 | 10 mil thickness (5 mil useful probe life) | |||||||||

| 20 | 20 mil thickness (10 mil useful probe life) | ||||||||||

| 50 | 50 mil thickness (25 mil useful probe life) | ||||||||||

| Code | ER Probe Shield Options | ||||||||||

| -S | 0 | No shield DUPLEX SS INCONEL | |||||||||

| 1 | Standard shield | ||||||||||

| 2 | Hi-velocity shield | ||||||||||

| Code | Element Alloy Material | ||||||||||

| -xxx | Code | Probe Characteristic Length | |||||||||

| -xxx | mm | ||||||||||

| For Example:EP100-B1-C1-T20-S0-A105-358 EP100 : Cylindrical Electrical Resistance Corrosion Probe B1: Body Material is 316SS C1: Connector Type: Standard connector T20: ER Element is 20 mil thickness (10 mil useful probe life) S0: No shield A105: Element Alloy Material is A105 358:Probe length is 358mm | |||||||||||

1. Construction and Design

The EMT-CP features a fully welded structure, crafted from premium materials including options like 316 SS, 316L SS, Duplex Stainless Steel (DSS), and INCONEL. These materials are known for their exceptional resistance to corrosion and mechanical stress, making the probe well-suited for use in extreme environments. The probe’s assembly includes an extension rod that houses the sensitive measuring element and a threaded connecting seat, ensuring a secure attachment within the system.

Each component of the EMT-CP probe is welded and hermetically sealed to enhance structural integrity and durability. The interface end of the probe is specially sealed using high-temperature glass sintering technology, which provides a reliable seal against extreme temperatures and pressures. This method ensures that the probe maintains its functionality and accuracy even under the most challenging conditions.

2. Features and Specifications of the Corrosion Probe Transmitter EMT-CP

The EMT-CP Corrosion Probe Transmitter is engineered to deliver high performance and reliability under extreme conditions. Here we expand on the key features and specifications that make this device essential for industrial applications dealing with harsh environments and demanding operational requirements.

Temperature Rating

The EMT-CP is uniquely designed to operate over a wide temperature range, making it suitable for diverse industrial applications:

- Range from -200°C to 260°C. This lower temperature range allows the probe to function effectively in environments where extremely low temperatures are common, such as in cryogenic processes involving liquid natural gas (LNG) or other gases that are stored or transported at cryogenic temperatures. The ability to operate at such low temperatures is crucial for ensuring the integrity and safety of pipelines and storage vessels in these sectors.

- Range from 260°C to 450°C. The higher temperature range addresses the needs of operations exposed to elevated temperatures, which are typical in refining, chemical manufacturing, and power generation. This capacity ensures that the probe can withstand and accurately measure in environments where temperatures exceed typical industrial levels, providing reliable data for corrosion monitoring and thereby helping to prevent potential failures and extend the lifespan of critical assets.

Pressure Rating

- Up to 45 MPa. The EMT-CP’s ability to withstand pressures of less than 45 MPa positions it as an ideal choice for high-pressure access systems. This high-pressure capability is essential for applications within oil and gas production, where pressures can significantly exceed atmospheric pressure. The robust design ensures that the probe maintains its structural integrity and operational effectiveness even under such extreme pressure conditions. This feature is particularly important for maintaining continuous and safe operations, as well as for ensuring accurate data collection from the internal environment of pipelines and vessels under pressure.

Mounting

- Compatibility with Access System using Hollow Plug. The probe’s design includes compatibility with a hollow plug access system, which is a critical feature for industries that require a non-invasive and efficient method to monitor and maintain their piping systems. This mounting feature allows for:

- Easy Installation and Retrieval. The probe can be inserted or removed from the pipeline using a probe nut and sealing ring that secure it to the hollow plug. This setup supports quick and simple installation and retrieval processes that do not require the pipeline operation to be halted, thereby minimizing downtime and maintaining continuous process flow.

- Continuous Monitoring with Minimal Disruption. Since the EMT-CP can be accessed and managed without stopping the operation of the system, it facilitates ongoing monitoring and data collection. Continuous monitoring is crucial for early detection of corrosion and other anomalies that could lead to system failures.

- Service Valve and Retrieval Tool Usage. The integration with a service valve and retrieval tool enhances operational flexibility and safety. Operators can perform maintenance tasks and probe management safely and efficiently. It also reduces the risk of exposure to the process medium and maintaining system integrity during probe handling.

3. Installation and Usage

Installing the EMT-CP is straightforward. The probe is attached to the hollow plug using a probe nut and sealing ring, which ensures a tight and secure fit. Once assembled, the probe-plug unit can be installed or retrieved from the process line using a specialized retrieval tool and service valve, thereby allowing maintenance and monitoring without interrupting the pipeline operation.

A protective cap is available for the sensor element of the probe, providing additional protection against physical damage and exposure to harsh substances, further extending the life and reliability of the probe.

4. Additional Components

It should be noted that the EMT-CP requires a probe adapter to connect to the data collector, which must be ordered separately. This adapter is essential for the transmission of corrosion data to the monitoring systems, enabling real-time corrosion monitoring and data analysis.

There are no reviews yet.