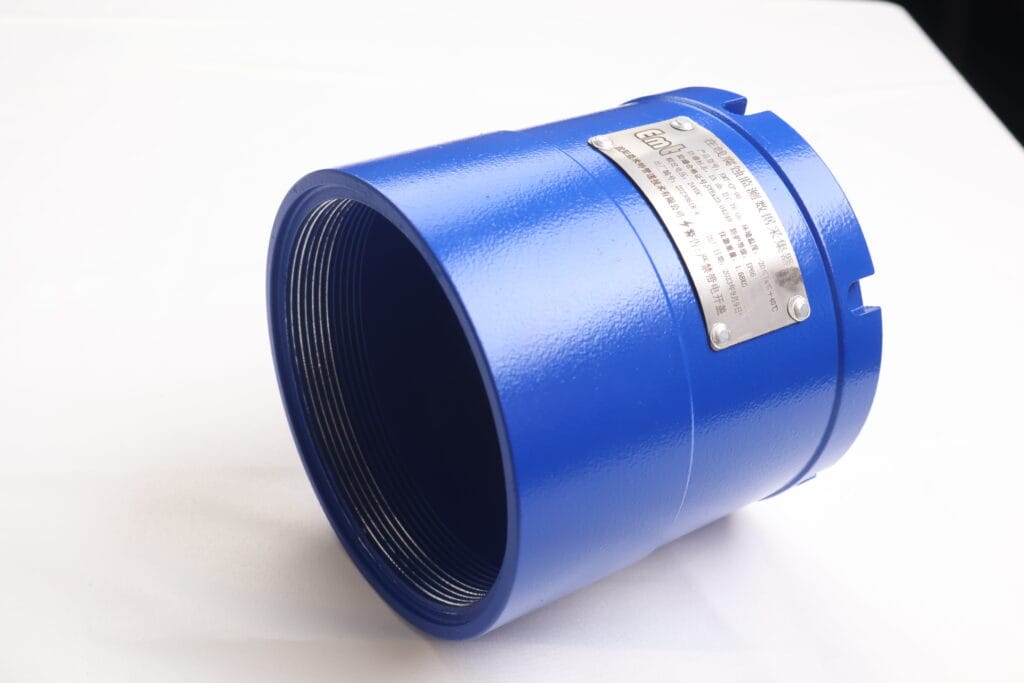

The EMT-CP High Corrosion Probe Coupon is an advanced corrosion coupon designed for the rigorous assessment of hydrogen permeation in steel pipelines. This probe is pivotal for industries where hydrogen-induced damages such as embrittlement, blistering, and decarburization can lead to critical failures in pipeline integrity.

1. Key Features and Advantages

Ease of Operation

The EMT-CC Corrosion Probe Coupon is deliberately designed to simplify the installation and usability aspects, dramatically reducing the complexity typically associated with such advanced instruments. This user-friendly approach minimizes the need for extensive operator training, thereby reducing training costs and simplifying the integration process into existing pipeline operations. Operators can install and begin monitoring with minimal setup time, making it an ideal choice for applications where quick deployment is necessary.

High Accuracy and Longevity

Engineered with precision, the EMT-CC Corrosion Probe Coupon delivers exceptionally accurate data, crucial for the real-time monitoring and early detection of potential pipeline integrity issues. This high level of accuracy ensures that any signs of hydrogen-induced corrosion can be detected as early as possible, allowing for timely preventative measures to be taken before significant damage occurs. The robust construction and quality materials used in the probe provide enhanced durability and longevity. It ensuring that it remains reliable over long operational periods even under harsh environmental conditions.

Cost Efficiency

Despite its advanced features and high-end specifications, it is designed to be an economically viable solution for pipeline monitoring. The cost-effectiveness of the probe makes it an attractive option for pipeline operators who require high-performance monitoring without the high capital expenditure typically associated with such technology. This budget-friendly nature extends to its maintenance and operational costs, as its durable design and ease of use reduce the need for frequent replacements or complex maintenance procedures.

Flexible and Lightweight

The materials selected for the EMT-CC probe, such as Stainless Steel 316 and L DUPLEX Stainless Steel. It not only offers superior corrosion resistance but also contributes to the overall light weight of the unit. This lightweight design, combined with its flexibility, allows for easier handling and installation, making it suitable for various pipeline configurations and locations. Whether it needs to be mounted in confined spaces or integrated into complex pipeline networks, the probe’s flexibility facilitates hassle-free installation.

Precise Location Tracking

Equipped with advanced location tracking technology, the EMT-CC probe provides precise data on the specific areas of pipeline monitoring. This capability is crucial for pinpointing the exact locations of potential or existing issues, allowing for targeted maintenance and repairs. Accurate location tracking enhances the effectiveness of the pipeline integrity management program, ensuring that resources are appropriately allocated to areas with the highest need, thereby optimizing operational efficiency and safety.

2. Construction and Material Composition

Materials:

- Probe Material. Stainless Steel 316, L DUPLEX Stainless Steel

- Sealing Material. Teflon, Fluororubber

- Access Fitting Body and Protective Cover Materials. Carbon Steel, 316L Stainless Steel, DUPLEX Stainless Steel

Design Specifications:

- Flange Size. ANSI 2″ RF (or RJ)

- Design Features. Includes access fitting body, protective cover, probe, hollow plug body, and integrated temperature & pressure gauge assembly

Operating Conditions:

- Temperature Range. -20 to 200℃

- Pressure Range. 0 to 26 MPa

Advantages:

- Lightweight and flexible design facilitates easy handling and installation.

- High injection efficiency and accurate location tracking optimize monitoring and maintenance efforts.

Constructed from robust materials such as Stainless Steel 316 and L DUPLEX Stainless Steel. The EMT-CC corrosion probe ensures high durability and resistance to harsh environments. The choice of these materials is strategic. They provide excellent resistance against corrosion and are capable of withstanding extreme conditions. Thus it ensures the longevity and reliability of the probe.

3. Sealing and Temperature Tolerance

For effective sealing, the probe utilizes Teflon and Fluororubber materials, known for their superior chemical inertness and thermal stability. These materials ensure airtight sealing, preventing any leakage and contamination that could skew monitoring results. Then the probe operates efficiently within a temperature range of -20 to 200℃, accommodating the varying thermal conditions that pipelines often experience.

4. Design and Functional Features

The EMT-CC Corrosion Probe Coupon is equipped with an access fitting body and a protective cover. Which can be either welded or flange-mounted to the pipeline. This flexibility in installation also allows for easy integration into existing pipeline systems. Then the probe’s design includes a hollow plug body and an integrated temperature and pressure gauge assembly, enabling accurate monitoring of internal conditions without necessitating frequent maintenance or calibration.

The access fitting body comes in options such as Carbon Steel, 316L Stainless Steel, and DUPLEX Stainless Steel, with sizes available in ANSI 2″ RF (or RJ) flange sizes. So this variability ensures that the probe can be tailored to meet specific pipeline specifications and pressure requirements, supporting pressures up to 26 MPa.

There are no reviews yet.