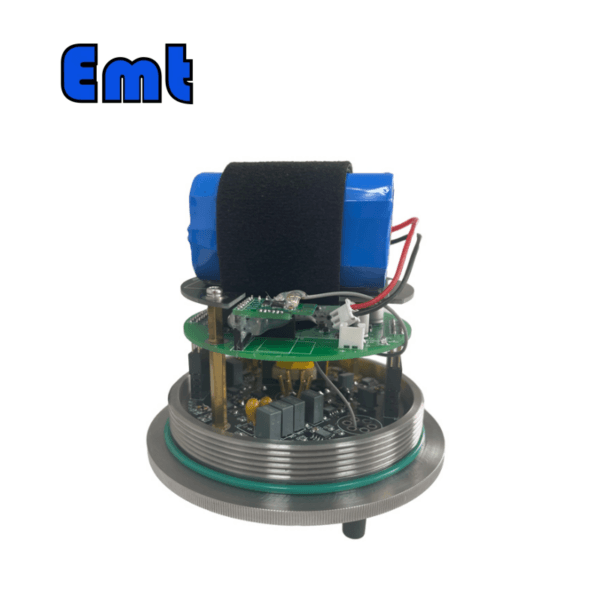

The EMT Corrosion Monitoring Probe is an important tool for monitoring pipeline corrosion rate. Its operation involves multiple steps, including installation, calibration, data recording and analysis.

| Name | EMT Corrosion Monitoring Probe | |

| Material | Stainless Steel 316、L DUPLEX SS | |

| Operating Temperature | -20~200℃ | |

| Feature | Firstly, easy to Operating | |

| Secondly, high Accuracy Long Life | ||

| At last, high-Efficiency Low cost | ||

| Payment | TT/LC | |

| Advantage | Firstly, they are lightweight and flexible. | |

| And then nice Injection efficiency. | ||

| At last, accurate location tracking. |

1. Features and advantages

Real-time monitoring:

The bypass monitoring pipeline corrosion rate probe can monitor the corrosion inside the pipeline in real time, detect and deal with corrosion problems in time, and avoid accidents.

High accuracy:

The equipment adopts advanced measurement principles and technologies, and can provide accurate and reliable corrosion rate data, providing a scientific basis for pipeline maintenance and maintenance.

Easy operation:

The bypass monitoring pipeline corrosion rate probe is easy to operate and install. It adopts a modular design, making the installation and disassembly process simple and fast.

Automatic calibration and fault self-diagnosis:

Some equipment also has automatic calibration and fault self-diagnosis functions, which can ensure the accuracy and reliability of monitoring data and reduce maintenance costs and workload.

Strong adaptability:

The bypass monitoring pipeline corrosion rate probe is suitable for various pipeline systems and corrosive environments, including offshore platforms, oil and gas fields and other complex working conditions.

2. Operation method

A. Installation steps

1. Select a suitable installation location: Before installing the ER Corrosion Monitoring Probe, you need to select a suitable installation location. Generally, the probe should be installed in a low-lying area or an area susceptible to corrosion in the pipeline to ensure that the corrosion rate of the pipeline can be accurately monitored.

2. Prepare installation tools: Some special installation tools are required to install the ER corrosion rate probe, including screwdrivers, wrenches, clamps, etc. Make sure these tools are complete and in good condition.

3. Install the probe: Fix the ER Corrosion Monitoring Probe in the selected position and firmly install it on the pipeline using a clamp or other appropriate fixing device. Make sure that the probe is in close contact with the pipeline surface to ensure the accuracy of the measurement results.

4. Connect the cable: Connect the cable between the probe and the data logger to ensure that the connection is firm and reliable to avoid loosening or falling off during use.

B. Calibration steps

1. Calibration equipment: Before performing corrosion rate measurements, the ER corrosion rate probe needs to be calibrated. The calibration equipment is also usually provided by the manufacturer and is operated according to the equipment manual.

2. Calibration steps: Connect the calibration equipment to the probe and calibrate according to the steps in the equipment manual. During the calibration process, some parameters may need to be adjusted, such as sensitivity, measurement range, etc., to ensure that the probe can accurately measure the corrosion rate.

C. Data Recording and Analysis

1. Data Recording: After the calibration is completed, the corrosion rate measurement can be started. Connect the data collector to the probe, set the appropriate measurement interval and recording time, and ensure that the corrosion rate data can be accurately recorded.

2. Data Analysis: The collected corrosion rate data needs to be further analyzed and processed. Professional data analysis software can also be used to process the data, draw a corrosion rate curve, and analyze the changing trend and influencing factors of the corrosion rate.

D. Precautions

1. Regular inspection: In order to ensure the accuracy and reliability of the ER Corrosion Monitoring Probe, it is necessary to regularly check the working status and data recording of the probe. If any abnormality is found, it should be handled and repaired in time.

2. Maintenance: During use, attention should be paid to the maintenance of the probe to avoid mechanical damage and chemical corrosion. Clean and lubricate the probe regularly to keep it in good working condition.

3. Safety protection: When installing, calibrating and recording data of the ER Corrosion Monitoring Probe, attention should be paid to safety protection to avoid safety accidents such as electric shock and falls.

3. Working principle

Electrochemical principle:

Some ER corrosion rate probes work on the electrochemical principle and reflect the corrosion situation by measuring the potential change on the metal surface. When the metal surface corrodes, its potential changes. Then the probe captures these changes and converts them into electrical signal output to deduce the corrosion rate.

Resistance measurement principle:

Another common ER corrosion rate probe uses the resistance measurement principle. This probe determines the amount of metal loss by measuring the change in metal surface resistance, and then obtains the corrosion rate. The change in resistance is closely related to the degree of corrosion of the metal material. So the corrosion situation can be evaluated by measuring the resistance value.

4. Application scenario

At last, bypass monitoring pipeline corrosion rate probes are widely used in pipeline systems in the oil, natural gas, chemical, water supply and other industries. It can also be used to monitor the corrosion of the inner wall of the pipeline, evaluate the degree and trend of pipeline corrosion, and provide an important basis for pipeline maintenance and maintenance.

There are no reviews yet.