EMT-CI Corrosion Coupon in Pipeline is critical tools used within pipeline systems to monitor and measure the rate of corrosion on metal samples, commonly referred to as coupons. These coupons are exposed directly within the pipeline or container environments, and by analyzing the corrosion rate in mils-per-year, they provide essential insights into the material’s durability and predict its lifespan.

Order Information

Access Fitting Body

| Model | ||||||

| EMT-CIPA | Access Fitting Body of Coupon, Injector, Probe assembly | |||||

| – The material of Access Fitting Body | ||||||

| 0 | CS | |||||

| 1 | 316SS | |||||

| 2 | 316LSS | |||||

| 3 | DUPLEX SS | |||||

| The Type of Access Fitting Body | ||||||

| B | 2″Welded(suffix “pressure rating” can be added to B) | |||||

| F | 2″ANSI Flange(suffix “pressure rating & sealing type” can be added to F) | |||||

| -Tee Size- pressure rating & sealing type if flanged end | ||||||

| 0 | No Tee | |||||

| 1 | 1/4″NPT(F)Tee | |||||

| 2 | 1/2″NPT(F)Tee | |||||

| 3 | 3/4″NPT(F)Tee | |||||

| 4 | 1″NPT(F)Tee | |||||

| 5 | Hole for 1/4″SWN Flange | |||||

| 6 | Hole for 1/2″SWN Flange | |||||

| 7 | Hole for 3/4″SWN Flange | |||||

| 8 | Hole for 1″SWN Flange | |||||

| -Protective Cover Type/ Material | ||||||

| 0 | No Protective Cover | Material | ||||

| 1 | Without hole | CS or 0 | ||||

| 2 | With hole | SS or 1 | ||||

| 3 | Bleed Valve | DSS or 3 | ||||

| 4 | Bleed Valve, & Pressure Gauge | |||||

| For Example:EMT-CIPA-0F600#RF-2-1/CS shows 2″ANSI 600#RF Flange Access Fitting Body in CS, 1/2″NPT(F)Tee, Protective Cover in CS without hole 0F600#RF: 0F_ Access Fitting Body is Flanged in CS , 600#RF _Size is 2″ANSI 600#RF , 2:Tee size is 1/2NPT(F) 1: Protective cover type is without hole /CS: Protective cove material in CS | ||||||

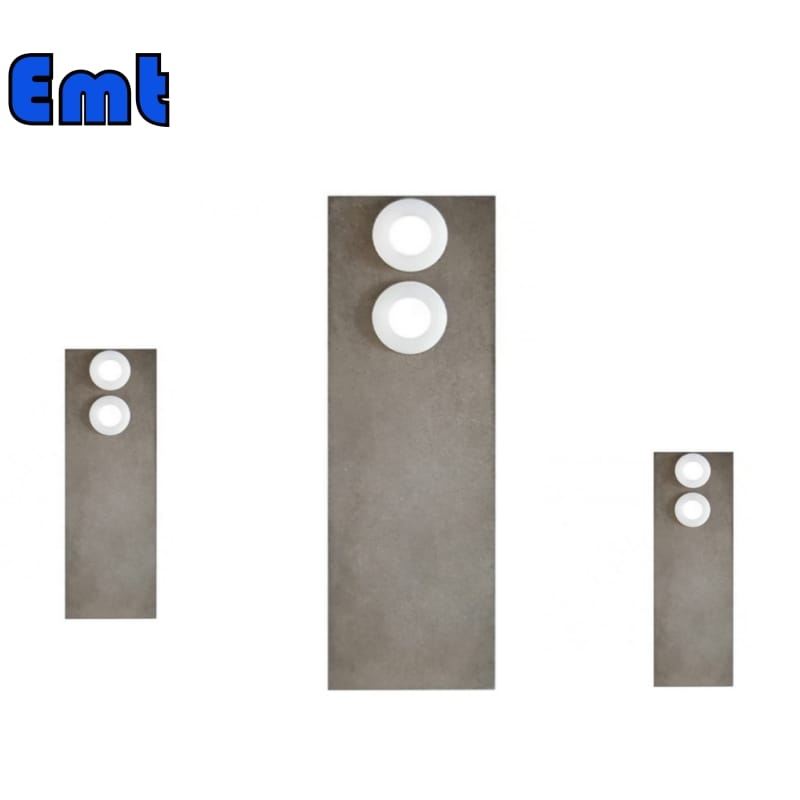

Corrosion Coupons

| Model | |||||||||||||

| CC | Corrosion Coupons | ||||||||||||

| -Code | Plug Body Assembly | ||||||||||||

| Pxxx | Type | Material | Sealing Material | ||||||||||

| 0 | No Request | 0 | CS | 0 | No Request | ||||||||

| 1 | Hollow Plug Body | 1 | 316SS | 1 | Viton O-Ring / PTFE Primary Packing | ||||||||

| 2 | Solid Plug Body | 2 | 316LSS | 2 | HNBR | ||||||||

| 3 | DUPLEX SS | ||||||||||||

| 4 | INCONEL | ||||||||||||

| Type of Coupon Holder | |||||||||||||

| SR | Fixed Coupon Holder for assembling rectangular coupon | ||||||||||||

| AR | Adjustable Coupon Holder for assembling rectangular coupon | ||||||||||||

| LR | Ladder Coupon Holder for assembling rectangular coupon | ||||||||||||

| SC | Fixed Coupon Holder for assembling circular coupon | ||||||||||||

| AC | Adjustable Coupon Holder for assembling circular coupon | ||||||||||||

| -Pipe Size | |||||||||||||

| x | Pipe Size in inch | ||||||||||||

| – Coupon Size | |||||||||||||

| A×B×C | Coupon Size in inch or mm | ||||||||||||

| – Coupon Material | |||||||||||||

| x | Grade | ||||||||||||

| -Finishing of Coupon | |||||||||||||

| 0 | Mill | ||||||||||||

| 1 | Glass Bead | ||||||||||||

| – Isolation Gasket | |||||||||||||

| 0 | No Gasket | ||||||||||||

| 1 | Nylon Gasket | ||||||||||||

| 2 | FTFE Gasket | ||||||||||||

| For Example:CC-P221-SR-6″-3″×1/2″×1/8″-MS1018-0-2 CC: Corrosion Coupons P221: Solid Plug Body in 316LSS Viton O-Ring and PTFE Primary Packing SR-6″:Fixed Coupon Holder for assembling rectangular coupon and for 6″pipe 3″×1/2″×1/8″: Coupon Size MS1018: Coupon Material 0: Finishing of Coupon is Mill 2: Material of Isolation Gasket is PTFE | |||||||||||||

Example for a set of Corrosion Coupons Assembly:

EMT-CIPA-0F600#RF-0-1+ CC-P221-SR-6″-3″×1/2″×1/8″-MS1018-0-2

Key Features of the Corrosion Coupon in Pipeline

- Corrosion Monitoring: EMT-CI Corrosion Coupon in Pipeline directly measures the corrosion rate in pipelines and containers, providing valuable data on the degradation of materials and predicting their life expectancy.

- Design and Installation:

- High-Pressure Access Systems: These include an access fitting body, plug assembly, and cover, which can be either welded or flange-mounted to pipelines.

- Standardized Connections: Typically uses ANSI 2” RF or RTJ for secure and standardized connections.

- Internal Components:

- Solid Plug Body and O-Ring: Ensure a robust seal within the pipeline.

- PTFE Primary Packing: Offers additional sealing to maintain integrity under different pressures.

- Coupon Holder: Available in fixed and adjustable forms to accommodate different coupon sizes and shapes, suitable for both rectangular and circular coupons.

- Dimensions and Materials:

- Coupon Sizes: Include common dimensions such as 3″×1″×1/8″ and 2″×1″×1/8″, among others for specific applications.

- Material and Sealing: Constructed from materials specified per Material Request (MR) with sealing materials like Fluororubber or Teflon for high durability and chemical resistance.

- Operational Ratings:

- Temperature and Pressure: Can operate within temperatures ranging from -20 to 200°C and pressure ratings from 150LB to 1500LB, accommodating a wide range of industrial conditions.

- Integration with Systems:

- Compatibility with Sampling & Injection Systems: Facilitates the extraction of medium samples or the injection of chemicals, which are crucial for managing corrosion and maintaining pipeline integrity.

Application and Installation:

Corrosion coupons are integrated into pipeline systems using high-pressure access systems. These systems typically consist of three primary components:

- Access Fitting Body: This can be either welded or flange-mounted to the pipeline, providing a secure and stable connection.

- Plug Assembly: Ensures a tight and secure seal within the fitting body, safeguarding the internal components.

- Cover: Protects the internal elements from external environments and contaminants.

The process connection for these flange-mounted systems is generally standardized to ANSI 2” RF (Raised Face) or RTJ (Ring Type Joint), depending on the specific application requirements.

Internal Assembly Components:

The internal assembly of the corrosion coupon includes a range of components designed for durability and effectiveness:

- Solid Plug Body and O-Ring: These elements ensure the integrity of the seal within the pipeline.

- PTFE Primary Packing: Provides additional sealing support, crucial for maintaining the system’s integrity under varying pressures.

- Coupon Holder: Available in fixed and adjustable versions to accommodate different coupon sizes and shapes. This holder can be specifically tailored for either rectangular or circular coupons, ensuring versatility in monitoring.

- Coupon: Standard sizes include 3″×1″×1/8″ and 2″×1″ ×1/8″, with options for smaller dimensions to suit various pipeline diameters.

Technical Specifications:

- Material Specifications: As per Material Request (MR) to ensure compatibility with the pipeline contents.

- Sealing Material: Made from high-quality Fluororubber or Teflon, providing exceptional resistance to chemical exposures and high temperatures.

- Operating Conditions: These coupons are rated for temperatures ranging from -20 to 200°C and can withstand pressures from 150LB up to 1500LB, making them suitable for a diverse range of industrial applications.

Sampling and Injection Compatibility:

EMT Corrosion Coupons work in tandem with Sampling & Injection Systems. These systems facilitate the extraction of medium samples from the pipeline or the injection of chemicals, which can influence the corrosion rate and thus the efficacy of corrosion inhibitors used within the system. The nipple, valve, and SWN flange sizes, corresponding with the types of the Injection and Sampling Systems, include 1/4”, 1/2”, 3/4”, and 1”.

There are no reviews yet.