1. Overview

Corrosion monitoring is essential for assessing the integrity and extending the lifespan of industrial equipment and pipelines. Corrosion Coupon and Probe, two of the most reliable methods for evaluating the corrosion levels within these systems are the use of corrosion coupon and probe. These tools provide direct, effective, and economical solutions for corrosion assessment and management.

2. Corrosion Coupons

Functionality:

Corrosion coupons are simple, standardized test pieces of metal installed within a pipeline or vessel. The primary purpose of a corrosion coupon is to measure the rate of corrosion by analyzing the loss in mass of the coupon over a set period under operational conditions. This method allows operators to determine the corrosive characteristics of the medium, calculate corrosion rates, and estimate the average service life of the system.

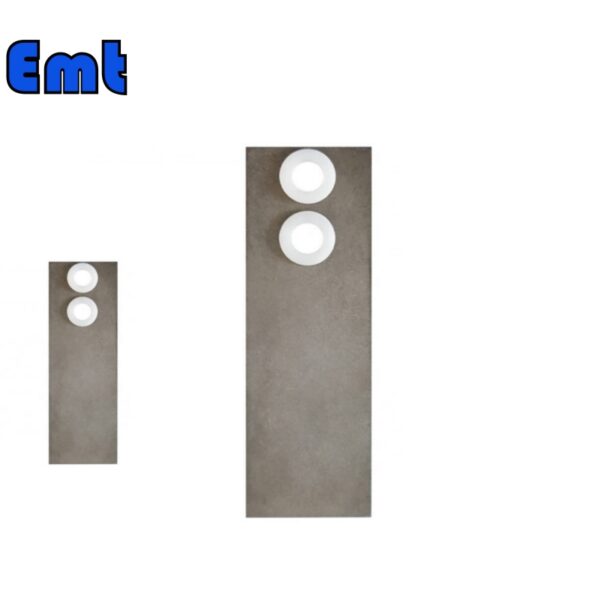

Components:

A typical corrosion coupon assembly consists of a pedestal, protective cover, plug, coupon support, and the coupon itself. These components ensure that the coupon is exposed to the same environmental conditions as the rest of the system.

Installation and Specifications:

- Flange Specification: ANSI 2″RF (or RJ)

- Welded Tube Support: 2″

- Operating Conditions: Suitable for temperatures ranging from -20 to 200°C and pressures up to 26 MPa.

- Coupon Specifications: Available in various sizes, such as 3″×1/2″×1/16″, and materials, including 316L and duplex stainless steel, to match the system requirements.

3. ECP Series Resistance Probes

Functionality:

ECP series resistance probes monitor corrosion by detecting changes in the resistance of sensing components when exposed to a corrosive medium. These probes provide real-time data on the corrosion status, enabling timely interventions to prevent safety and operational risks due to equipment degradation.

Design and Installation:

The probe is available in cylindrical and sheet resistance types, ensuring versatility for different monitoring needs. It can be installed via welding or flange, depending on the system’s configuration. The probes are made from robust materials like 316L and F51 duplex stainless steel, with Teflon and fluororubber seals to withstand harsh conditions.

Operating Conditions:

- Temperature Range: -20 to 200°C

- Pressure Rating: Up to 26 MPa

- Installation Options: Supports both flange and welded installations, with specifications like ANSI 2″RF flange sizes.

4. Differences Between Corrosion Coupon and Probe

Corrosion coupon and probe are both used for monitoring the rate and extent of corrosion in industrial systems such as pipelines and vessels. However, they function based on different principles and offer different kinds of data. Understanding the distinctions between these two methods can help in selecting the appropriate monitoring technique based on specific requirements and conditions.

a. Principle of Operation

Corrosion Coupons:

- Direct Measurement: Corrosion coupons work on a simple principle where pre-weighed pieces of metal are exposed to the corrosive environment for a fixed period. After retrieval, the coupons are cleaned and reweighed to determine the mass lost due to corrosion. This loss is to calculate the corrosion rate.

- Passive Monitoring: They do not provide real-time data but instead offer a cumulative indication of the corrosive environment over the period of exposure.

ECP Series Resistance Probes:

- Indirect Measurement: These probes measure the corrosion rate indirectly by detecting changes in electrical resistance of a metallic element as it corrodes within the process stream.

- Active Monitoring: Resistance probes provide real-time monitoring of corrosion rates, allowing for immediate detection of changes in the corrosive conditions.

b. Data Acquisition and Analysis

Corrosion Coupons:

- Periodic Analysis: The analysis is done intermittently, as the coupons need to be physically removed for weighing and inspection. This method provides data points that reflect the average corrosion rate over the exposure period.

- Manual Intervention: Requires manual intervention for installation and retrieval, which can be labor-intensive and might require system downtime.

ECP Series Resistance Probes:

- Continuous Monitoring: Probes continuously send data to a monitoring system, enabling ongoing assessment of corrosion rates and trends.

- Automated Data Collection: Typically connected to data loggers or corrosion monitors, these probes require minimal manual handling once installed.

c. Installation and Maintenance

Corrosion Coupons:

- Simpler Installation: Generally easier to install, involving a holder or a plug in the pipeline or vessel. However, changing coupons necessitates system access and potential downtime.

- Maintenance Requirements: Regular removal and replacement of the coupons are necessary, which also involves handling potentially hazardous materials.

ECP Series Resistance Probes:

- Complex Installation: Might require specific fittings such as flanges or welds and potentially more complex initial setup.

- Lower Ongoing Maintenance: Once installed, they do not usually need to be removed for maintenance and can operate for extended periods without intervention.

d. Material and Environmental Suitability

Corrosion Coupons:

- Material Specificity: Coupons can also be made from the same material as the system components, providing direct correlation data for specific materials.

- Environmental Versatility: Effective in almost any system where they can be physically installed and exposed to the medium.

ECP Series Resistance Probes:

- Limited by Electrical Properties. The effectiveness can depend on the electrical properties of the metals used in the probes and might not be suitable for all types of corrosive environments.

- High-Pressure and Temperature Capability. Often designed to withstand extreme conditions without direct exposure to the process medium.

There are no reviews yet.