Understanding Corrosion and the Role of Corrosion Coupons

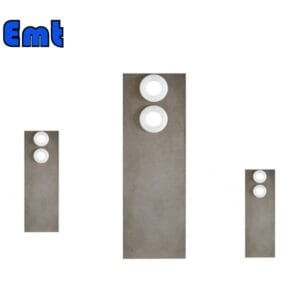

Corrosion and Coupon

Corrosion is a natural process that deteriorates materials, typically metals, due to chemical interactions with their environment. This process can lead to significant damage in infrastructure, particularly in pipelines, tanks, and other metallic structures. Monitoring and mitigating corrosion is crucial in industries such as oil and gas, water treatment, and chemical processing to ensure safety, reliability, and longevity of equipment.

What is Corrosion?

Corrosion can manifest in several forms, depending on the environment and the material involved:

Uniform Corrosion: This occurs evenly across exposed surfaces and is often the easiest type of corrosion to detect and measure.

Pitting Corrosion: Highly localized and can lead to sudden failures due to its ability to create small, deep pits in the material.

Galvanic Corrosion: Occurs when two dissimilar metals are in contact in a conductive solution, causing one metal to corrode more rapidly than the other.

Crevice Corrosion: Found in metal-to-metal or metal-to-nonmetal crevices where a localized aggressive environment can form.

Stress Corrosion Cracking: Combines the effects of tensile stress and a corrosive environment, leading to cracking.

Specifications

| Material | Stainless Steel 304、Stainless Steel 316、DSS F51、Carbon Steel A105N、Inconel 625 |

| Operating Temperature | -20±120℃ |

| Features | Firstly, Easy to Operating |

| Secondly, High Accuracy Long Life | |

| At last, High Efficiency, Low cost | |

| Payment | TT/LC |

| Advantages | Firstly, they are lightweight and flexible. |

| Secondly, Nice Injection efficiency. | |

| At last, Accurate location tracking. |

Role of Corrosion Coupons

Corrosion coupons are an integral part of a comprehensive corrosion monitoring strategy. They are small, standardized samples of metal that are exposed to an environment where corrosion is expected to occur. Here’s how they are used:

Monitoring: By installing corrosion coupons in strategic locations within a system, one can gauge the rate and type of corrosion occurring over time.

Data Collection: After exposure, coupons are retrieved and analyzed to measure the loss of material mass, evaluate surface degradation, and determine the severity of pitting or other forms of corrosion.

Predictive Analysis: The data from coupons can help predict future corrosion behavior, guiding maintenance schedules and the application of corrosion inhibitors.

Material Selection: Testing different materials as coupons can determine the most corrosion-resistant material for specific conditions.

Benefits of Using Corrosion Coupons

Cost-Effective: Corrosion coupons provide a low-cost method for assessing corrosion rates compared to more complex monitoring technologies.

Simplicity: The use of coupons does not require sophisticated equipment or training, making it accessible for regular maintenance teams.

Direct Measurement: They offer direct empirical data on the corrosive effects within the actual system environment.

Material Specificity: Coupons can be constructed from the same materials as the system being monitored, ensuring relevant and specific insights.

Conclusion

Corrosion coupons are a valuable tool in the arsenal of any industry that deals with metallic structures and systems. By providing direct, actionable data on the types and rates of corrosion, these coupons play a critical role in the effective management of infrastructure, ensuring safety and efficiency while minimizing downtime and repair costs. Their simple yet effective nature makes them an indispensable part of routine maintenance and monitoring programs.

There are no reviews yet.