Overview of Retractable Injection Quills

Chemical Injection Quill Assembly mean a significant advancement in fluid delivery systems. These tools make it feasible for specific, controlled shot of chemicals right into pressurized systems without interruption. Manufacturers make them to withdraw, permitting simple upkeep and adjustment without shutting down the system. This function substantially improves functional versatility and safety.

Significance in Industries

In the chemical market, retracting shot quills make sure the precise application of reactants, vital for maintaining item top quality and security. Drug applications get from their precision, which is essential for the rigorous demands of medication production. In water therapy, these quills play an important role in the sanitation treatment, effectively metering chlorine and various other therapy chemicals to ensure public health. Each sector values the quill’s capacity to provide compounds effectively and safely, revealing its worldwide value.

What is Retractable Chemical Injection Quill Assembly?

A retractable injection quill is an ingenious tool made use of to instill chemicals right into a pressurized pipeline securely and efficiently. Unlike fixed quills, this kind features a retracting layout that makes it possible for drivers to withdraw it from the pipe without stopping system procedure. This capacity is essential for keeping continual procedure circulations and sees to it low disruption throughout upkeep or adjustments.

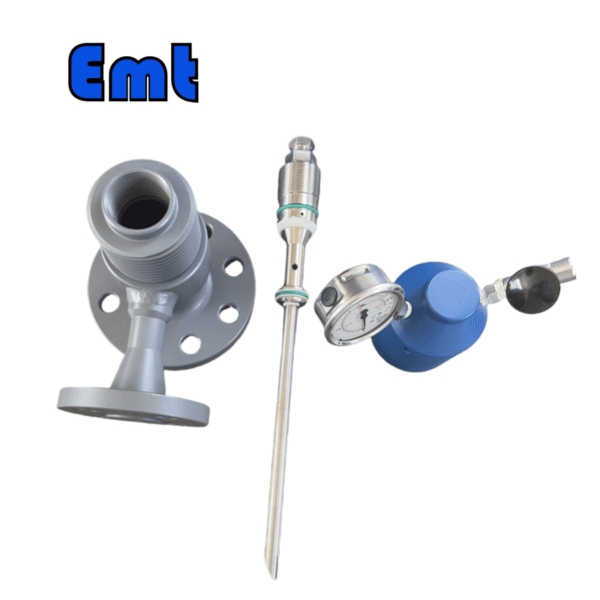

The basic design of a retractable injection quill consists of a durable body and a stinger, or nozzle, that extends right into the pipe. Manufacturers frequently utilize corrosion-resistant items such as PVC, Kynar, 316 stainless-steel, or Hastelloy C-276 for construction to take on severe chemicals. The stinger, ranging from 3″ to 8″ in size, features multiple shot openings. These openings are actively positioned to boost the diffusion of chemicals right into the facility of the pipeline flow.

This design stays clear of the chemical from merely diminishing the pipe wall surface. Which can cause uneven circulation and prospective damages. Instead, it ensures that chemicals blend extensively with the process fluid, making the most of efficiency and performance. Furthermore, the quill includes females by male NPT web links, streamlining the installation process and enhancing compatibility with existing pipeline setups.

Key parts of Retractable Injection Quill

1. Quill Body

The quill body creates the primary structure of the shot quill. It is generally made from materials resistant to corrosion and chemical damage. Such as stainless-steel or specialized plastics. The body houses the inner components and web links directly to the pipe, providing security and durability for the shot procedure.

2. Shot Idea

The shot tip, or stinger, is a crucial component that prolongs right into the pipe. Created with accuracy, it features several holes wherein chemicals are infused right into the flow of the treatment liquid. The concept makes certain the even circulation of chemicals, preventing them from clinging to pipe wall surface areas and boosting the mixing efficiency.

Flange or Welded Link

A flange or bound web link work to link the shot quill strongly to the pipe. Flanged connections allow for simpler setup and elimination, perfect for systems asking for normal upkeep. Bonded links use a more irreversible solution, supplying robust securing and higher stress managing capabilities.

Installment

Shutoffs and installments regulate the circulation and pressure of chemicals entering the quill. These components are vital for specific control over the shot procedure, allowing drivers to adjust the price and quantity of chemical distribution according to the demands of the system.

Pipeline affixes the shot quill to the chemical supply source. It needs to be sturdy and suitable with the chemicals being made use of, typically made from the very same items as the quill body to assure regular resistance to deterioration and wear.

Mounting and Help Frameworks

Setting up and assistance frameworks provide security and placing for the injection quill within the pipeline system. These parts are essential for keeping the correct positioning of the quill, making certain that the shot procedure is both protected and effective under various operational problems.

Retractable Injection Quill Applications in Different Industries

1. Chemical Processing

Chemical Shipment: Injection quills advertise the details circulation of responsive and harmful chemicals in processes. Such as acid neutralization and solvent recovery.

Safety and security and Performance: They enhance security by lessening straight exposure and enhancing the performance of chain reactions via much better mixing.

2. Water Treatment

Sanitation: Typically used for the exact application of chlorine and various other anti-bacterials to ensure the safety of alcohol consumption water.

pH Law: Help in readjusting the pH of water by infusing alkaline or acidic alternatives. It is essential for keeping the balance needed for sure treatments.

3. Oil and Gas

Degeneration Control: Shot quills are crucial for providing wear and tear avoidances straight right into pipelines, for that reason prolonging their life-span and maintaining flow efficiency.

Scale Prevention: They instill range preventions to prevent the build-up of mineral deposits in pipes. Which can limit fluid flow and rise maintenance rates.

4. Pharmaceuticals.

Ingredient Mixing: Secret to presenting accurate quantities of energetic components and excipients into pharmaceutical services, seeing to it consistency and effectiveness of medicines.

Process Streamline: Aids improve the production treatment by enabling continual procedures without the requirement for constant quits. Which is crucial in settings that demand rigorous controls and repeatability.

There are no reviews yet.