1. Introduction

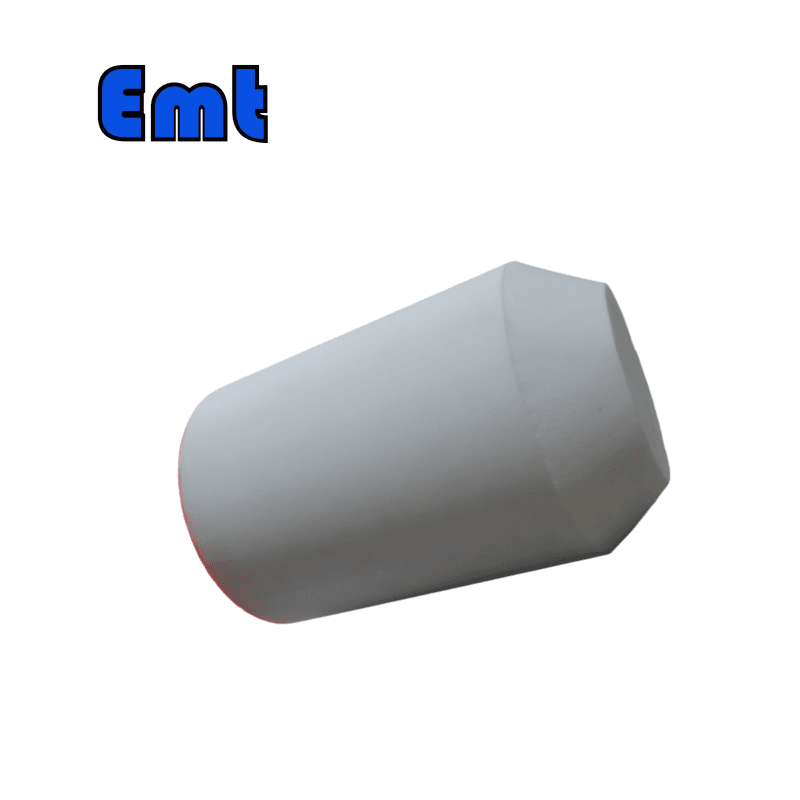

The EMT Bare Foam Pig, part of EMT Pigging’s specialized pipeline maintenance equipment, is designed to address various pipeline cleaning needs, including water absorption, sealing, cleaning, and descaling. This tool is essential for industries such as building material shops, construction works, energy and mining, and especially in pipeline pigging for the oil and gas sectors.

Polyurethane material specification:

| NO. | Factory inspection main indicators | Cup/DISC |

| 1 | 20℃Hardness(SHORE A) | 85±2 |

| 2 | Tensile strength (MPa) | 51.7 |

| 3 | 100%stress at definite elongation (MPa) | 4.8 |

| 4 | 300%stress at definite elongation (MPa) | 9.2 |

| 5 | Tensile set (%) | 780 |

| 6 | Tear strength (KN/m) | 73.0 |

| 7 | Impact resilience (%) | 32 |

| 8 | DIN abrasion (mm²) | 35 |

2. Key Attributes of the EMT Bare Foam Pig

- Type: Foam Pig

- Product Name: Pipeline Polyurethane Customized Density Soft Cleaning Pigs

- Brand Name: EMT Pigging

- Material: Made primarily from polyurethane, the Bare Foam Pig features a soft foam body with a density that ranges from 35 to 200 kg/m³. This material flexibility allows it to adapt to pipeline contours and obstructions effectively.

- Design Features:

- Starting Pressure: 0.02 MPa, making it suitable for operations even at low-pressure settings.

- Withstand Pressure: Up to 7 MPa, which ensures durability under various operational pressures.

- Stretch Rate: Impressive 320%, providing significant flexibility and adaptability to different pipe diameters.

- Compression Ratio: 60, which allows it to compress and expand, maintaining effectiveness across varying internal pipeline sizes.

- Attrition Rate: 4 mm per 100 km, indicating minimal wear over substantial distances.

- Flex Life: Capable of 50,000 flex cycles, highlighting its durability and longevity.

- Operating Conditions:

- Temperature Range: Functional from -30℃ to +100℃, ensuring performance stability in extreme temperature conditions.

- Operating Distance: Effective for distances ranging from 50 km to 150 km, suitable for long pipeline cleaning operations.

- Color: Available in red or white, allowing for visual identification during and after operations.

3. Features of the EMT Bare Foam Pig

Product Overview

- Type: Foam Pig

- Product Name: Pipeline Polyurethane Customized Density Soft Cleaning Pigs

- Brand Name: EMT Pigging

Material and Construction

- Material: The EMT Bare Foam Pig is primarily constructed from polyurethane, providing a robust yet flexible cleaning tool. Its soft foam body can be customized with densities ranging from 35 to 200 kg/m³. This versatility allows the pig to effectively conform to the contours of the pipeline and navigate around any obstructions it may encounter.

Design Features

- Starting Pressure: The pig operates effectively starting from a low pressure of 0.02 MPa, making it suitable for use in pipelines with low-pressure systems.

- Withstand Pressure: It is capable of withstanding pressures up to 7 MPa, ensuring that it remains functional and intact under various operational conditions.

- Stretch Rate: An impressive stretch rate of 320% allows the pig to adapt to different pipe diameters, enhancing its versatility across diverse pipeline architectures.

- Compression Ratio: With a compression ratio of 60, the pig can compress and expand, maintaining its effectiveness across varying internal pipeline sizes without compromising its structural integrity.

- Attrition Rate: Demonstrates minimal wear with an attrition rate of 4 mm per 100 km, indicating its durability and suitability for long-distance operations.

- Flex Life: The EMT Bare Foam Pig can endure up to 50,000 flex cycles, highlighting its long-term durability and resilience in frequent and repeated use scenarios.

Operating Conditions

- Temperature Range: It remains operational in a wide range of temperatures, from -30℃ to +100℃. This feature ensures stable performance in environments experiencing extreme cold or heat.

- Operating Distance: Effective for cleaning operations ranging between 50 km and 150 km, it is ideal for extensive pipeline systems requiring regular maintenance over long distances.

- Color Options: Available in red or white, these color choices provide clear visual identification during and after pigging operations, facilitating easier monitoring and retrieval.

Application

- Specific Use: The EMT Bare Foam Pig is specially designed for a variety of pipeline cleaning tasks, including water absorption, sealing, thorough cleaning, and descaling. Its material and design allow it to effectively remove debris and residues, ensuring that pipelines remain clear and functional.

4. Packaging and Delivery

- Packaging: Each pig is packaged in a sturdy plywood case to ensure it arrives in optimal condition.

- Package Size: Each pig measures 6x6x10 cm, making it compact and easy to handle.

- Weight: Each unit has a gross weight of 1.000 kg, lightweight enough for easy transportation and handling.

- Certifications: ISO 9001 certified, affirming the quality and reliability of the product.

- Additional Services:

- Video Outgoing-Inspection: Provided, ensuring the product meets quality standards before shipment.

- Machinery Test Report: Also provided, offering detailed insights into the specifications and performance of the foam pig.

5. Industry-Specific Utility

The EMT Bare Foam Pig is designed to be versatile and effective in various industrial environments. Its robust design and high-performance materials make it an essential tool for maintaining pipeline integrity and efficiency in sectors where pipeline systems are critical to operations. This includes oil and gas pipeline maintenance, where regular cleaning and descaling are necessary to prevent blockages and maintain flow efficiency. Additionally, its lightweight and adaptable nature make it suitable for construction-related pipeline applications, where flexibility and durability are key requirements.

There are no reviews yet.