Quick Opening Closure for Pig Launcher

A Quick Opening Closure (QOC) is a vital component in pig launcher systems used for pipeline cleaning and maintenance. This device enables rapid and safe access to the pig launcher, facilitating the insertion and retrieval of pipeline pigs.

Key Features of a Quick Opening Closure

Speed and Efficiency: Designers have made the QOC to open and close quickly, significantly reducing downtime during pipeline maintenance operations. This feature is crucial for operations where time constraints are critical.

Safety Mechanisms: The QOC features safety interlocks and mechanisms that prevent accidental opening while the system is pressurized. These features ensure that operators can only operate the closure under safe conditions, protecting maintenance personnel.

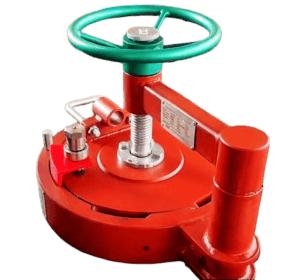

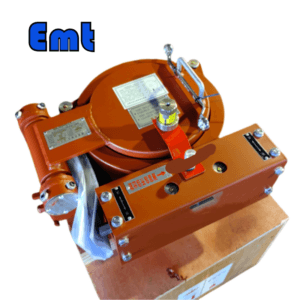

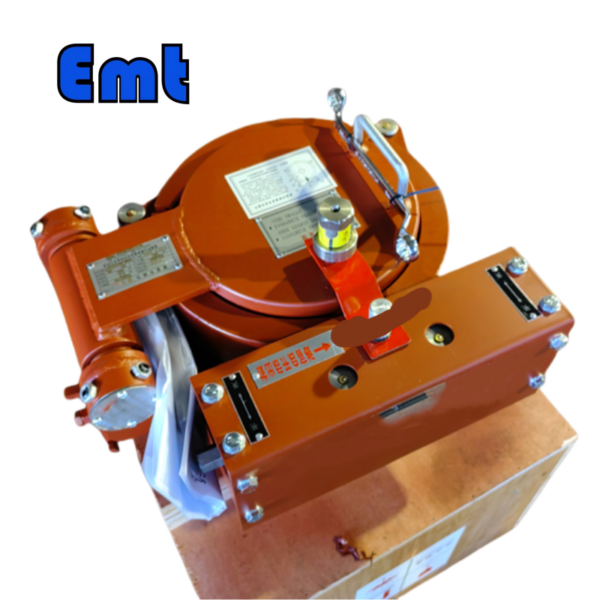

Ease of Operation: Typically, QOCs are engineered for simple operation. They often include features such as hand wheels or hydraulic actuation systems that facilitate easy and effort-free opening and closing, even under high-pressure conditions.

Durability and Reliability: Manufacturers use robust materials to make QOCs capable of withstanding harsh operational environments, ensuring they endure the extreme pressures and temperatures commonly found in pipeline systems.

Different Types

| Lock Ring Type | Band Type | Plug Buckle Type | |

| Installation | Vertical/Horizontal | Vertical/Horizontal | Vertical |

| Size | DN 200 to DN 1200 | DN 150 to DN 1000 | DN 150 to DN 1000 |

| Pressure | ASME #150 to #1500 | ASME #150 & #300 | ASME #150 to #600 |

| Materials | SA 350 LF2 | SA 350 LF2 | SA 516 70N/SA 105N |

| Sealing | Viton™ | Viton™ | Viton™ |

Basic Regulations

The nominal diameter of the QOC shall comply with the provisions of GB/T 1047. When the nominal diameter is greater than 700mm, it should be selected as an integer multiple of 100mm. Nominal pressure shall comply with the provisions of GB/T 1048. In addition to meeting the strength, sealing performance, and corrosion resistance required by the working condition, it should also be flexible and convenient to open and close. Safety interlocking devices should be set up and warning signs should be set up at appropriate locations.

Quick Opening Closure should meet the following requirements:

a) When the Quick Opening Closure reaches the predetermined closing position and the safety interlock device is in place, operators can increase the pressure in the equipment.

b) Operators can only open the Quick Opening Closure when they have completely released the internal pressure of the equipment and removed the safety interlock device.

The inner diameter of the cylinder flange should be consistent with the inner diameter of the connected cylinder. Seals should have good sealing performance during the service life. The designed service life shall not be less than the designed service life of the equipment. Bring an operation hand wheel or special wrench to ensure flexible and convenient opening and closing. The design, manufacture, inspection, and acceptance shall also meet the relevant requirements of the equipment design document. The Quick Opening Closure introduced shall meet the requirements of TSG 21 and Y/T 0556-2018.

Maintenance

Regular maintenance and proper lubrication are crucial for extending the lifespan and ensuring the reliable operation of Quick Opening Closures (QOC) in pig launcher systems. In addition to the initial steps of greasing the QOC components after each operation, it’s important to check and replenish lubricants regularly to prevent corrosion and wear. Operators should conduct frequent inspections to assess the condition of seals and gaskets and replace them as necessary to ensure a tight seal and prevent leaks. They should also clean any debris from the moving parts and the closure mechanism to ensure smooth operation. By adhering to a thorough maintenance schedule, operators can avoid operational delays and maintain the safety and efficiency of the pipeline system.

Maintenance and lubrication operation of the quick-opening closure

(1) Grease the QOC each time you operate it.

(2) Lubricate the hinge shaft.

(3) Lubricate bolts, nuts, and slide rails.

(4) Lubricate drain bolts (threads and O-rings).

Replace the seal ring

(1) Every time you operate the quick opening closure, check the seal. Replace the seal if it is not tight or damaged.

(2) Use engine oil lubrication, be careful of the sealing ring including the groove on the quick opening closure.

(3) The position of the sealing ring should be correct when installing it. The sealing groove must face outward. Install an anti-fly spring behind the washer.

Daily Inspection

(1) Check whether the lock ring and the lock ring ear are deformed, and whether the support clip is correctly installed.

(2) Check whether the sealing surface of the door is clean and has no mechanical damage or rust.

(3) Check whether the contact surface of the door and lock ring is clean and not corroded.

(4) Check with your eyes whether the screw buckle of the pressure relief bolt hole is intact and not corroded.

(5) Check the sealing surface of the pressure relief bolt for damage.

(6) Remove the lock ring to check whether the door is centered; changes within 0.2mm are permissible.

There are no reviews yet.