Introduction to Pressure Vessel Closure

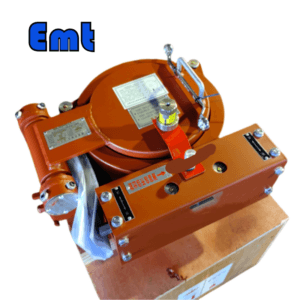

EMT Pressure Vessel Closure is an essential component that ensures the safety and efficiency of various industrial applications. Designed to seal vessels operating under high pressure, these closures are critical in industries such as chemical processing, oil and gas, and power generation. Their robust design guarantees that the contents remain securely contained, effectively preventing leaks and maintaining the required system pressure. Key features of pressure vessel closures include versatile installation options. They offer compatibility with different sizes and pressure ratings. The closures exhibit superior material strength for durability. They also have advanced sealing capabilities to prevent leaks. These attributes enable them to meet diverse operational demands. Additionally, they adhere to stringent regulatory standards. This makes them vital for safe and reliable industrial operations.

Pressure vessel closures are crucial components designed to safely seal vessels that operate under high pressure in various industrial applications. These closures ensure that the contents of the vessel remain securely contained, preventing leaks and maintaining the necessary internal pressure required for optimal performance. Industries such as chemical processing, oil and gas, and power generation rely heavily on these closures to ensure safety and efficiency in their operations.

Design Features

The design of pressure vessel closures incorporates robust materials that can withstand extreme conditions, including high temperatures and corrosive environments. Key features include versatile installation options, compatibility with various sizes and pressure ratings, and advanced sealing technologies that enhance reliability. Many closures also offer additional safety features, such as pressure relief mechanisms, to prevent catastrophic failures.

Overall, pressure vessel closures play a vital role in maintaining the integrity of industrial systems. Their ability to meet stringent regulatory standards and diverse operational demands makes them essential for ensuring safe and efficient processes in critical applications.

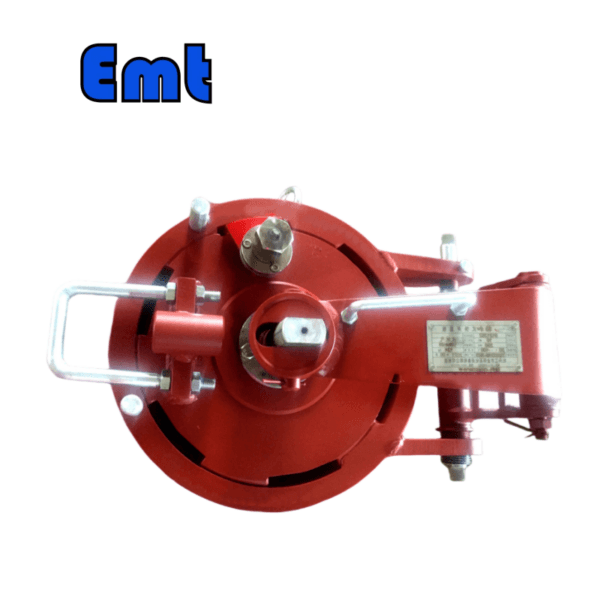

Different Types of Pressure Vessel Closure

| Lock Ring Type | Band Type | Plug Buckle Type | |

| Installation | Vertical/Horizontal | Vertical/Horizontal | Vertical |

| Size | DN 200 to DN 1200 | DN 150 to DN 1000 | DN 150 to DN 1000 |

| Pressure | ASME #150 to #1500 | ASME #150 & #300 | ASME #150 to #600 |

| Materials | SA 350 LF2 | SA 350 LF2 | SA 516 70N/SA 105N |

| Sealing | Viton™ | Viton™ | Viton™ |

Types of Pressure Vessel Closures

Pressure vessel closures come in various designs, each tailored to specific applications and operational requirements. Understanding the different types is essential for selecting the right closure for a given pressure vessel.

Bolted Closures: These are among the most common types of pressure vessel closures. They utilize bolts and flanges to create a secure seal. Bolted closures allow for easy access to the vessel contents for maintenance and inspection while providing a robust seal under high pressure. They are widely used in chemical processing and oil and gas applications.

Welded Closures: Welded closures provide a permanent seal by welding the closure to the vessel. This type is ideal for applications requiring high integrity and safety, as it minimizes the risk of leakage. Welded closures are often found in high-pressure vessels, such as those used in power generation and aerospace.

Clamp-style Closures: These closures use a clamping mechanism to secure the vessel lid. They offer quick access to the vessel contents and are often used in situations where frequent opening and closing are necessary. Clamp-style closures are common in food processing and laboratory applications.

Quick-Opening Closures: Designed for rapid access, these closures allow for quick opening and closing without tools. They are particularly useful in processes that require frequent sampling or maintenance. Quick-opening closures are often used in the pharmaceutical and petrochemical industries.

Pressure Relief Closures: These closures incorporate safety features such as pressure relief valves. They automatically vent excess pressure, preventing potential explosions or catastrophic failures. Pressure relief closures are critical in any application where pressure build-up is a concern, ensuring safe operation.

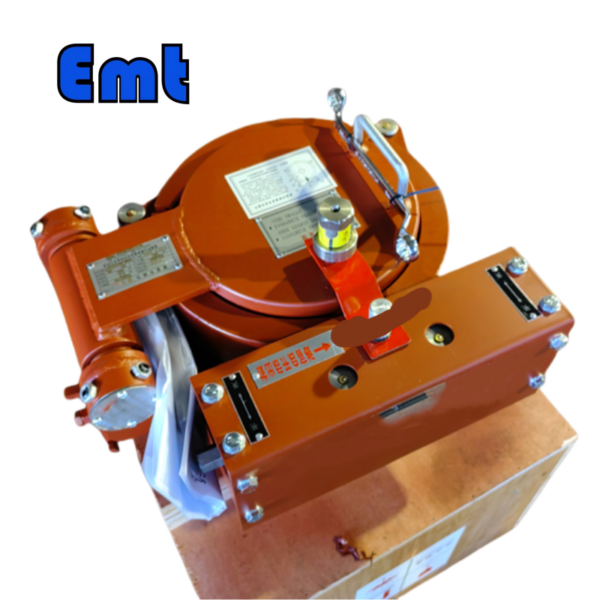

Parameters

| Technical indicators | |

| Nominal Diameter DN: | <1800mm |

| Design pressure PN: | ≤40 MPa |

| Working Medium: | oil, gas, water |

| Design Temperature: | -50℃~300℃ |

| Material: | 16Mn,A350LF2, A105, SS304, SS316, F51, F53, F55, INCONEL625, HASTELLOY C |

| Pipe Thickness: | 6mm~100mm |

Applications of Pressure Vessel Closure

Pressure vessel closures find extensive applications across various industries due to their essential role in maintaining safety and efficiency. Here are some key applications:

Chemical Processing:

In chemical plants, pressure vessel closures securely contain reactive substances under high pressure, preventing leaks and ensuring safe operations.

Oil and Gas:

These closures are critical in the extraction, transportation, and storage of oil and natural gas, where they help maintain system integrity and safety.

Power Generation:

Pressure vessels in power plants, including those used in boilers and reactors, rely on robust closures to handle high-pressure steam and other fluids safely.

Food and Beverage:

These closures are used in the processing and storage of food and beverages, helping to maintain quality and safety during production.

Water Treatment:

In water treatment facilities, pressure vessel closures are essential for containing chemicals used in purification processes, ensuring safe handling and operation.

There are no reviews yet.