Pipeline Scraper Pig from EMT Pigging, designed to maintain the cleanliness and efficiency of your pipeline systems. Over time, pipelines can accumulate deposits and residues that decrease transportation efficiency, leading to increased operational costs. Regular cleaning with the right equipment is essential to avoid these issues and ensure smooth operation.

1. Product Description

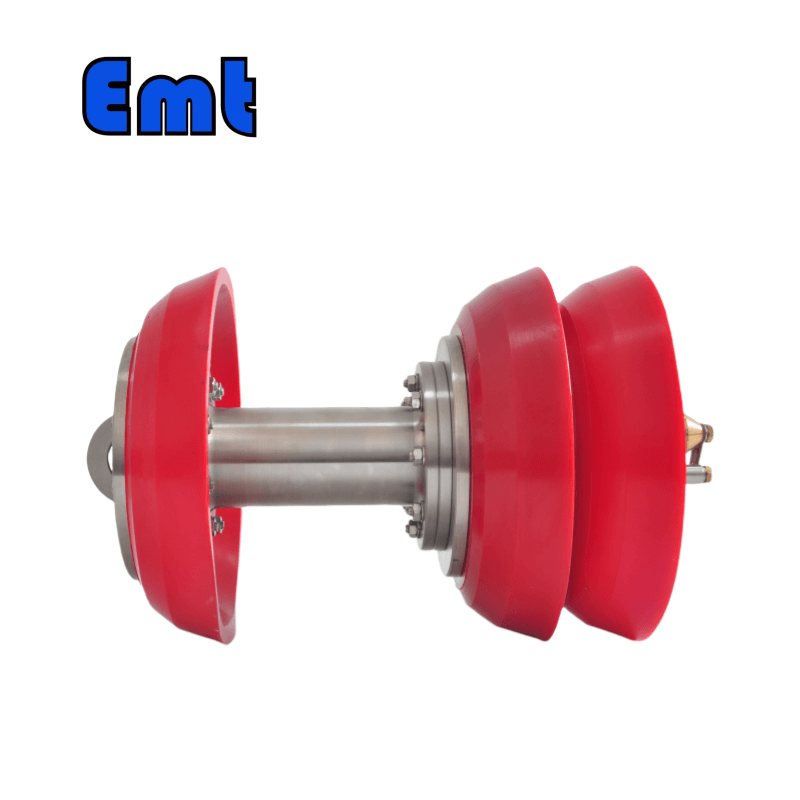

Product Name: Custom Polyurethane 3 Cups Pipeline Scraper Pig

Brand Name: EMT Pigging

Condition: New

Technical Specifications:

- Material: Durable Polyurethane for the cups with a robust Carbon Steel middle section.

- Color: Red

- Size Range: Available from 2 inches to 60 inches, with options for customization to fit specific pipeline dimensions.

- Design Temperature: Operable from -40°C to +120°C, suitable for various environmental conditions.

- Tool Designation: Polyurethane Cups Pipeline Pig

- Main Accessories: Equipped with three polyurethane cups.

- Drive Interface Type: Utilizes a polyurethane cup mechanism for effective cleaning action.

2.Product Benefits

Maintaining Pipeline Integrity and Efficiency

The Pipeline Scraper Pig is a critical tool designed to uphold the structural and operational integrity of pipelines. Regular use of this pigging device helps clear out debris, scale, and other unwanted residues that accumulate over time and could potentially hinder the flow of materials through the pipeline. By ensuring these obstructions are removed, the pipeline maintains a higher level of operational efficiency, which is crucial for the smooth and uninterrupted transport of liquids and gases. This not only helps in avoiding pressure drops and energy losses. It but also prevents the long-term degradation of pipeline materials, thereby extending the lifespan of the infrastructure.

Cost Reduction

One of the key benefits of implementing a regular pigging schedule with this device is the significant reduction in operational costs. By maintaining clean and efficient pipelines, companies can avoid costly breakdowns and downtime that result from blockages or inefficient pipeline operations. Additionally, by preserving the integrity of the pipeline, the need for expensive repairs and replacements is minimized. The efficiency gained also translates into lower energy costs needed to pump fluids through the pipeline, offering further economic benefits.

Customizable Features

The adaptability of the Custom Polyurethane 3 Cups Pipeline Scraper Pig to various industrial needs is another standout benefit. It can be tailored with additional components such as gauging discs to assess internal pipeline conditions, magnetic inserts to collect ferrous materials, or different types of cleaning brushes suited to specific residue types. These customizable options allow the pig to be specifically configured for different pipeline profiles, materials handled, and the specific maintenance needs of various industries, making it a versatile tool in any pipeline maintenance arsenal.

Broad Industrial Applicability

The robust design of this pipeline pig makes it suitable for a wide array of applications beyond just oil and gas pipelines. In construction and mining operations, where large quantities of debris and sediment can accumulate and disrupt operations, Pipeline Pig plays a vital role in routine maintenance to ensure operational continuity. Additionally, its use in water and sewage treatment facilities to maintain flow and prevent blockages underscores its utility in a broad spectrum of industrial sectors.

3. Applications

Primary Use: Pipeline Pigging

The primary application of the Custom Polyurethane 3 Cups Pipeline Pig is for pipeline pigging. Which is a critical maintenance operation in pipeline management. This tool is specifically designed to navigate through pipeline systems to remove accumulated deposits such as scale, wax, and other residues that can impede the smooth flow of materials. By effectively cleaning these deposits, the pipeline pig helps maintain optimal pipeline efficiency and flow rate, which is essential for minimizing operational disruptions and maintaining throughput. Regular pigging with this tool can also help identify potential issues within the pipeline. Such as cracks or build-ups, before they escalate into major problems, thus aiding in proactive maintenance and reducing the risk of pipeline failures.

Other Uses: Drainage Systems and More

Beyond its primary function in pipeline maintenance, the Pipeline Pig is also adept for use in various other applications:

- Drainage Systems: The pig is suitable for cleaning and maintaining drainage systems where water resistance is crucial. Its robust design ensures that it can withstand environments where water or moisture is prevalent, helping to clear blockages and ensuring that drainage systems operate effectively. This capability is particularly valuable in preventing flooding or water damage. Especially in areas prone to heavy rainfall or in industrial settings where water management is critical.

- Dielectric Isolation: The pig’s construction materials, particularly polyurethane, provide excellent dielectric properties, making it suitable for applications requiring electrical insulation. This feature is important in industries where pipelines might carry fluids that can conduct electricity or where pipelines are laid in proximity to electrical installations. By providing dielectric isolation, the pipeline pig helps prevent electrical accidents and enhances safety during maintenance operations.

- Versatile Industrial Applications. The Pipeline Pig’s flexible design and robust construction make it suitable for a variety of other applications across different sectors. Whether it’s oil and gas, mining, or construction, this tool can be adapted to meet specific operational needs. For instance, with the addition of accessories like wire brushes or magnetic steel, the pig can be customized for more aggressive cleaning or for specific tasks like collecting metallic debris, respectively.

Customization Options:

- Enhance your Pipeline Scraper Pigwith optional accessories such as magnetic steel for capturing ferrous debris, gauging discs to measure internal anomalies, guide discs to navigate pipeline bends, wire brushes for tough deposits, spring brushes for flexibility, or a transmitter for tracking and location purposes.

4. Key Certifications:

- ISO 9001 Certified: Ensures compliance with international quality standards.

5. Packaging and Delivery Details:

- Selling Units: Sold as a single item.

- Package Dimensions: 40 x 40 x 75 cm.

- Gross Weight: 8.000 kg.

There are no reviews yet.