The Principle of Lock Ring Type Quick Open Closure

The principle of Lock Ring Type Quick Open Closure is to close and open the pipeline through the connection of the upper cover and the lower cover. When the pipe needs to be closed, the upper cover and the lower cover are connected by locking screws. And the sealing ring can play a sealing role, to realize the isolation of the medium. Loosen the locking screw to open the pipe. Separate the covers to quickly remove the closure. Use the lock ring Quick Open Closure for various piping systems. It suits hydraulic, air, and water systems. Its simple structure allows easy installation and disassembly. Widely use it in large pipeline systems.

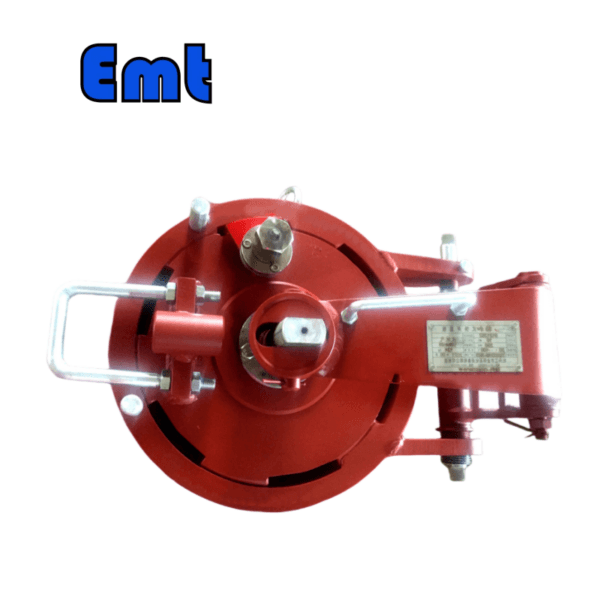

The safety lock ring is used to fix the working position of the ring lock. When the ring lock is attached to the inclined surface of the simplified ring groove, insert the safety lock plate between the two lever arms to prevent the radial displacement of the ring lock.

Composition and installation

First, the lock ring

The locking ring is one of the core components of the lock ring’s quick-opening closure, and its main function is to fix and seal the plate. In general, the lock ring is usually made of carbon steel or stainless steel and other materials. The connection mode of the lock ring has two kinds of flange connection and clamp connection, and the user should choose the corresponding lock ring connection mode according to their specific needs.

Second, QOC

Plates are another key component of lockring quick-opening closures and are usually made of the same material, the same standard, and the same shape. The user should choose the appropriate QOC specification according to the pipe size, pressure, and other factors.

Three, sealing gasket

A sealing gasket is a key component to prevent fluid leakage, and users should usually choose the appropriate sealing gasket material and type according to the size of the QOC and lock ring and the characteristics of the medium.

Installation Procedure of Quick Open Closure

1. Before installation, the user should check the lock ring, and sealing gasket to ensure that their size and material meet the design requirements.

2. Before installation, the gate valve should be installed at the sealing place of the valve port to ensure the safety of the QOC installation.

3. Attach the sealing gasket to the QOC, and place the QOC and sealing gasket at the sealing place of the valve port.

4. Put the lock ring on the QOC, and tighten the lock ring nut and bolt.

5. Firmly connect the QOC, sealing gasket, and lock ring. Loosen the gate valve to discharge residual pressure.

Parameters

| Lock Ring Type | Band Type | Plug Buckle Type | |

| Installation | Vertical/Horizontal | Vertical/Horizontal | Vertical |

| Size | DN 200 to DN 1200 | DN 150 to DN 1000 | DN 150 to DN 1000 |

| Pressure | ASME #150 to #1500 | ASME #150 & #300 | ASME #150 to #600 |

| Materials | SA 350 LF2 | SA 350 LF2 | SA 516 70N/SA 105N |

| Sealing | Viton™ | Viton™ | Viton™ |

| Bandlock Quick Opening Closure | ||||

| Design Pressure | 1.6MPa-30MPa | |||

| Corrosion Allowance | 2mm | |||

| Seismic Fortification Intensity | 7 Degrees | |||

| Work Medium | Oil, natural gas, Water and ore pulp, etc. | |||

| Opening Time | Within 60s less than 200N | |||

| Opening Type | Vertical or Horizontal | |||

Matters Need Attention

Before installation, the user should carefully check the technical parameter table of the lock ring type quick opening closure. Then user should select the QOC, lock ring, and sealing gasket that meet the pipeline specifications and requirements. Finally, you ensure that these devices have the required certification and inspection report.

Install the lock ring quick-opening closure in the corresponding pipeline. Conduct pressure and sealing tests after installation to ensure safety and normal operation.

Quick Opening Closure is indispensable in oil and gas pipelines and plays an important role in pipeline pigging. Compared with the traditional QOC, the quick-opening closure has the characteristics of reasonable structure, good sealing performance, fast opening and closing, reliable performance, and easy operation.

Lock Ring Type Quick Open Closure security issues

The safety locking device of the Lock Ring Type Quick Open Closure significantly enhances its safety performance. It also prevents the radial movement of the lock ring, reducing the probability of the pressure switch QOC. However, if the pressure relief groove of the pressure alarm bolt or the relief port is blocked, this method cannot completely guarantee that the pressure in the container is zero. Therefore, completely remove the pressure alarm bolt to ensure that the pressure is zero. To prevent the combustion and explosion of ferrous sulfide in the container, spray water into the container to absorb and dissolve ferrous sulfide before fully opening the door.

Conclusion

The lock ring type quick opening closure is a widely used valve type. It offers convenient operation, good sealing, safety, and reliability. This paper details the components and installation steps of the locking ring quick-opening closure. We aim to provide users with a comprehensive guide for safe use.

There are no reviews yet.