Foam Balls in Pipeline Pigging

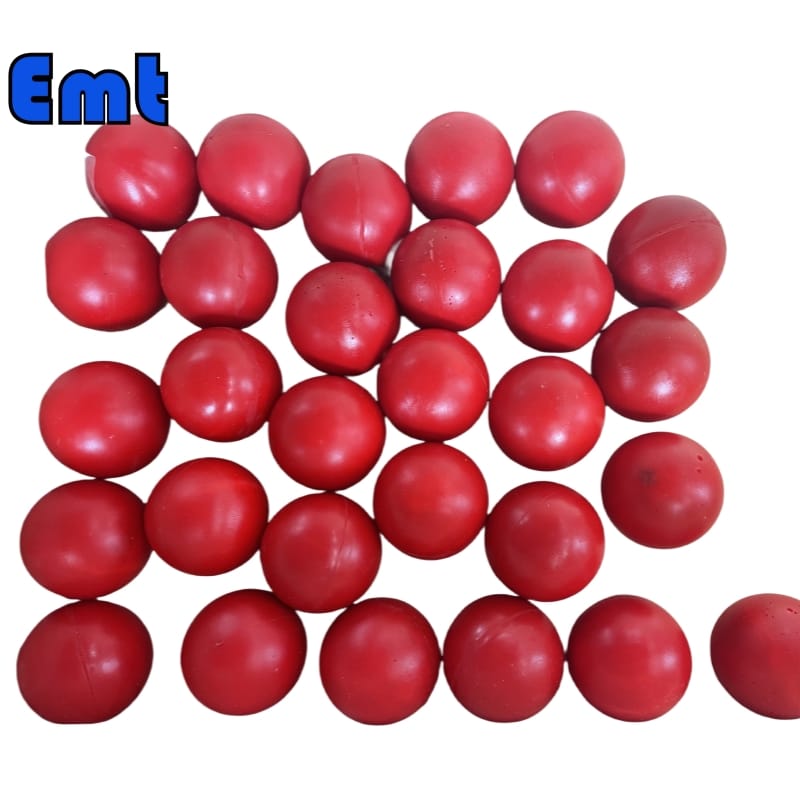

Foam balls are a type of pipeline pig used for cleaning, dewatering, and product displacement in pipelines. They are made from open-cell or closed-cell polyurethane foam and are highly flexible, allowing them to navigate bends, valves, and varying pipeline diameters effectively.

Features of Foam Balls

Foam balls in pipeline pigging are highly effective for various applications, including cleaning and debris removal. They help eliminate soft deposits, dust, and light debris from the interior of pipelines. They are also used for dewatering. The pigging balls assist in the removal of residual water or liquids after hydrostatic testing or maintenance. Additionally, they play a crucial role in product separation. They prevent contamination by separating different products in multiphase pipelines. Moreover, their flexibility allows them to navigate complex pipeline configurations. In addition, they can pass through tight bends and diameter variations, making them suitable for diverse systems. Furthermore, foam balls are cost-effective. They are lightweight, inexpensive, and often disposable. Thus, they offer a practical alternative to traditional metal pigs.

Foam balls are widely used in industries such as oil and gas, water distribution, food processing, and chemical transportation. Their effectiveness and adaptability make them a popular choice for regular pipeline maintenance and cleaning operations.

Parameters

| Name | Customized Foam Pig | ||||

| Material | Polyurethane | ||||

| Light Density | 0.02-0.3g/m3 | ||||

| Medium Density | 0.08-0.12g/m3 | ||||

| Heavy Density | 0.13-0.16g/m3 | ||||

| Feature | 1. High wear resistance | ||||

| 2. Good cleaning performance | |||||

| 3. Low cost | |||||

| Payment | TT/LC | ||||

| Advantage | 1. They are lightweight and flexible. | ||||

| 2. Nice cleaning efficiency. | |||||

| 3. Accurate location tracking. | |||||

Polyurethane Material Specification

| Polyurethane material specification: | ||

| NO. | Factory inspection main indicators | Cup/DISC |

| 1 | 20℃Hardness(SHORE A) | 85±2 |

| 2 | Tensile strength (MPa) | 51.7 |

| 3 | 100%stress at definite elongation (MPa) | 4.8 |

| 4 | 300%stress at definite elongation (MPa) | 9.2 |

| 5 | Tensile set (%) | 780 |

| 6 | Tear strength (KN/m) | 73 |

| 7 | Impact resilience (%) | 32 |

| 8 | DIN abrasion (mm²) | 35 |

There are no reviews yet.