The EMT ECP series ER Probe is a critical tool for corrosion monitoring, engineered specifically to track and evaluate corrosion rates in industrial settings. It operates by detecting variations in the resistance of its sensors when subjected to corrosive conditions. This functionality is pivotal for the timely identification of corrosion. It is crucial in averting equipment degradation and ensuring the safety of production processes. With a capacity to withstand pressures up to 26 MPa, the ER Probe is versatile enough to be used in a broad spectrum of industrial applications. Therefore it is an invaluable asset for maintaining the integrity and operational efficiency of industrial systems. This probe not only helps in protecting physical assets but also plays a significant role in optimizing maintenance strategies and reducing downtime.

Assembly of EMT ER Probe

Protective Cover

The protective cover of the ECP ER Probe for Corrosion Monitoring is an essential element of the probe’s design. Serving as a robust shield, it safeguards the probe’s delicate internal components from environmental pollutants, physical damage, and exposure to harsh chemicals. Constructed typically from 316L stainless steel, this cover is engineered to endure the severe conditions prevalent in industrial environments. Its durability ensures that the structural integrity of the probe is maintained, allowing it to perform reliably and extend its service life in settings that might otherwise compromise its functionality. This cover not only protects but also enhances the overall resilience of the probe, making it a crucial feature for consistent and accurate corrosion monitoring.

The protective cover of the ECP ER Probe for Corrosion Monitoring is an essential element of the probe’s design. Serving as a robust shield, it safeguards the probe’s delicate internal components from environmental pollutants, physical damage, and exposure to harsh chemicals. Constructed typically from 316L stainless steel, this cover is engineered to endure the severe conditions prevalent in industrial environments. Its durability ensures that the structural integrity of the probe is maintained, allowing it to perform reliably and extend its service life in settings that might otherwise compromise its functionality. This cover not only protects but also enhances the overall resilience of the probe, making it a crucial feature for consistent and accurate corrosion monitoring.

Digital Transmitter

The digital transmitter in an ER Corrosion Probe plays a pivotal role in enhancing the functionality and accuracy of corrosion monitoring systems. This component is responsible for converting the electrical signals, which correspond to the degree of corrosion detected by the probe, into digital data that can be easily interpreted and analyzed. The digital output allows for real-time monitoring, providing immediate feedback on the corrosive conditions within the system. This rapid data transmission is crucial for enabling prompt decision-making and interventions, which are essential for preventing extensive damage and maintaining operational safety.

Moreover, the integration of a digital transmitter in the ER Corrosion Probe facilitates seamless connectivity and compatibility with modern control systems and data analytics platforms. Providing data in digital form, enables a more detailed and sophisticated analysis of corrosion trends over time. This helps to predict potential failures before they occur. This capability not only enhances the preventive maintenance strategies but also contributes to extending the lifespan of equipment by ensuring that corrosion risks are managed effectively and efficiently.

Base

The welded base of the corrosion probe ensures a robust, secure attachment to the system it monitors. It forms a strong, permanent bond, providing stability and preventing dislocation under pressure. This feature significantly enhances the probe’s reliability and accuracy in harsh environments. Additionally, the welded design minimizes the risk of leaks at the connection point, crucial for maintaining the integrity of both the probe and the system. Overall, the welded base stands as a critical component, essential for long-term monitoring performance.

The welded base of the corrosion probe ensures a robust, secure attachment to the system it monitors. It forms a strong, permanent bond, providing stability and preventing dislocation under pressure. This feature significantly enhances the probe’s reliability and accuracy in harsh environments. Additionally, the welded design minimizes the risk of leaks at the connection point, crucial for maintaining the integrity of both the probe and the system. Overall, the welded base stands as a critical component, essential for long-term monitoring performance.

Probe Adapter

The probe adapter serves as a crucial link between the corrosion probe and the monitoring system. It facilitates easy and secure connection, enhancing the system’s overall integration. Moreover, this adapter allows for quick installation and removal of the probe, streamlining maintenance procedures. It also ensures consistent alignment and optimal contact, thereby improving signal accuracy and reliability. Ultimately, the probe adapter boosts the functional efficiency of the corrosion monitoring setup.

The probe adapter serves as a crucial link between the corrosion probe and the monitoring system. It facilitates easy and secure connection, enhancing the system’s overall integration. Moreover, this adapter allows for quick installation and removal of the probe, streamlining maintenance procedures. It also ensures consistent alignment and optimal contact, thereby improving signal accuracy and reliability. Ultimately, the probe adapter boosts the functional efficiency of the corrosion monitoring setup.

Plug Assembly

The plug assembly secures the internal components of the device, ensuring a tight seal against environmental contaminants. It locks in place to prevent any dislodgement, maintaining the integrity of the system throughout its operation. Additionally, this assembly facilitates the safe containment of pressures, crucial for the probe’s accurate performance in high-pressure environments. By protecting sensitive elements, the plug assembly enhances the durability and reliability of the monitoring equipment. Overall, it plays an essential role in sustaining the probe’s functionality and safety.

The plug assembly secures the internal components of the device, ensuring a tight seal against environmental contaminants. It locks in place to prevent any dislodgement, maintaining the integrity of the system throughout its operation. Additionally, this assembly facilitates the safe containment of pressures, crucial for the probe’s accurate performance in high-pressure environments. By protecting sensitive elements, the plug assembly enhances the durability and reliability of the monitoring equipment. Overall, it plays an essential role in sustaining the probe’s functionality and safety.

Resistance Corrosion Probe

The Resistance Corrosion Probe measures the corrosive effects within industrial systems with precision. It detects changes in metal resistance, indicating corrosion levels. This information helps operators to assess and manage the integrity of infrastructure effectively. Furthermore, the probe’s sensitive detection capabilities allow for early intervention, potentially preventing costly repairs and downtime. By continuously monitoring resistance, it ensures that maintenance schedules are timely and based on actual corrosion data, thereby enhancing system reliability.

The Resistance Corrosion Probe measures the corrosive effects within industrial systems with precision. It detects changes in metal resistance, indicating corrosion levels. This information helps operators to assess and manage the integrity of infrastructure effectively. Furthermore, the probe’s sensitive detection capabilities allow for early intervention, potentially preventing costly repairs and downtime. By continuously monitoring resistance, it ensures that maintenance schedules are timely and based on actual corrosion data, thereby enhancing system reliability.

At the core of the ECP series’ functionality is the resistance probe, designed to detect resistance changes due to corrosive processes on metal surfaces.

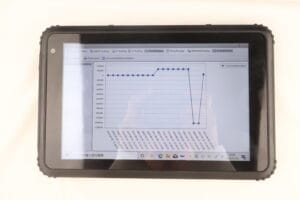

Portable Data Logger

The Portable Data Logger, when paired with an ER Corrosion Probe, becomes an effective tool for detailed corrosion monitoring. This setup tracks electrochemical changes that signify corrosion in infrastructure, recording data critical for assessing material degradation. The logger’s capacity to collect and store continuous data streams allows for a comprehensive analysis of corrosion trends over time. This setup not only enhances the detection of corrosion rates but also identifies potential failure points within the system. Consequently, it supports proactive maintenance strategies and helps in extending the lifespan of industrial equipment by ensuring that timely corrective actions are taken based on accurate corrosion data. Ultimately, this combination of the Portable Data Logger and ER Corrosion Probe offers a robust solution for maintaining system integrity and operational efficiency in corrosive environments.

There are no reviews yet.