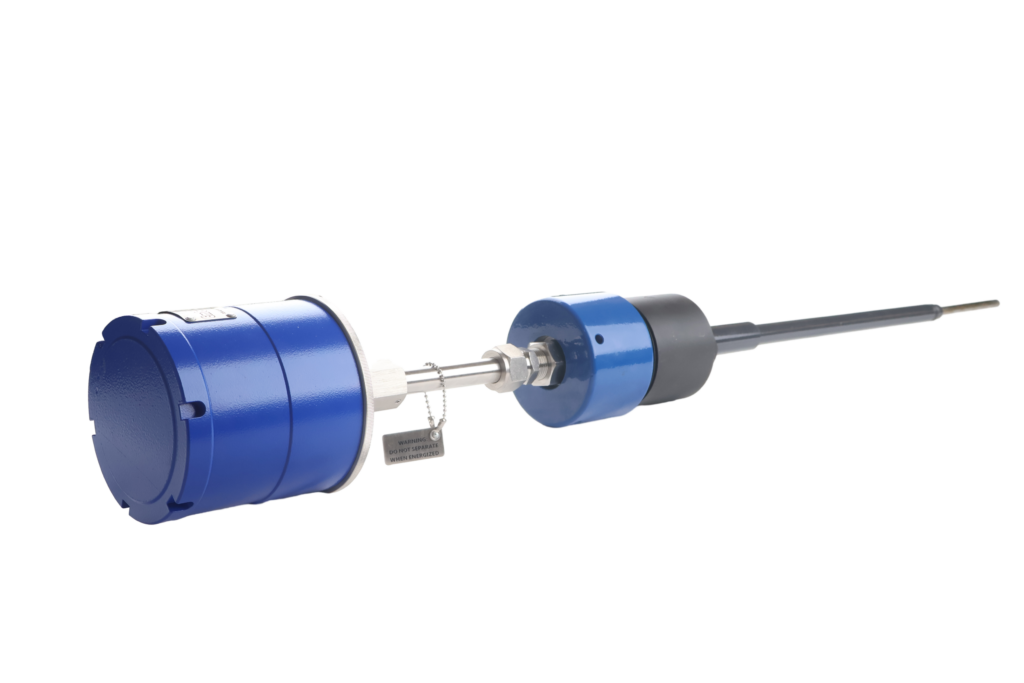

ER Corrosion Probe EMT-CP is an advanced instrument designed for precise corrosion monitoring in high-pressure environments. This fixed-length, retrievable probe is ideally suited for integration into high-pressure access systems, catering to industries where harsh conditions prevail.

Name | EMT ER Corrosion Probe EMT-CP |

Material | Stainless Steel 316、L DUPLEX SS |

Operating Temperature | -20~200℃ |

| Feature | 1.Easy Operating |

| 2.High Accuracy Long Life | |

| 3.High Efficiency Low cost | |

| Payment | TT/LC |

| Advantage | 1.They are light weight and flexible. |

| 2. Nice Injection efficiency. | |

| 3.Accurate location tracking. |

1. Specifications

- Temperature Rating. The probe operates effectively within a broad temperature range, offering two ranges: -200°C to 260°C and an optional range up to 450°C, accommodating various industrial applications.

- Pressure Rating. The probe rating for pressures up to 45MPa. It makes it suitable for high-pressure applications.

- Mounting. Designed for use with an access system that incorporates a hollow plug, facilitating easy integration and removal.

2. Key Features of the ER Corrosion Probe

- Robust Construction:

- Made from high-quality materials such as 316 SS, 316LSS, DSS, and INCONEL, ensuring durability and resistance to corrosive environments.

- Fully Welded Structure:

- The probe’s fully welded design enhances its suitability for harsh conditions by providing a secure seal and preventing media leakage.

- High-Temperature Glass Sintering:

- The interface end of the probe is sealed with high-temperature glass sintering, offering additional protection against extreme temperatures and pressures.

- Temperature and Pressure Ratings:

- Operates across a wide temperature range with two optional settings: -200°C to 260°C and 260°C to 450°C.

- Rated for pressures less than 45MPa, accommodating high-pressure applications.

- Retrievable and Fixed-Length:

- The probe has new design to be retrievable, allowing for easy installation and removal without the need to shut down the process, supporting continuous operations.

- Leakage Prevention:

- Integrates measures like integral welding of the measuring element to the probe body and filling the probe rod with heat and pressure-resistant filler to ensure media integrity.

- Mounting and Integration:

- Specifically designed for use with an access system featuring a hollow plug, facilitating seamless integration into pipeline systems.

3. Design and Construction

Material Selection and Durability:

The EMT-EP100 ER Corrosion Probe is constructed from a selection of high-grade materials known for their strength and resistance to corrosion. The use of 316 SS and 316LSS stainless steels provides excellent resistance against a wide range of chemicals and corrosive environments. Duplex Stainless Steel (DSS) offers even higher strength and toughness, which makes it ideal for demanding applications where mechanical and corrosion resistance is critical. Additionally, the inclusion of INCONEL, an alloy well-suited for extreme environments, enhances the probe’s capability to withstand high temperatures and corrosive pressures, making the EMT-EP100 exceptionally robust in hostile operational conditions.

Structural Integrity and Welding:

The probe’s fully welded structure is a key feature in its design, contributing significantly to its overall integrity and durability. This welding ensures that all components of the probe are securely joined, eliminating any potential weak spots that could lead to structural failures or media leakage. The hermetic sealing of each joint further reinforces this effect, creating a solid, unitary construction that can withstand the rigors of operational stresses without compromise.

Probe Assembly Components:

The probe assembly is a meticulously design for optimal performance and reliability. It includes:

- Extension Rod. This component houses the sensitive sensing element and is crucial for the transmission of corrosion data from the point of measurement to the monitoring system. The rod is designed to ensure that the sensor remains correctly positioned within the pipeline, maximizing its exposure to the internal environment for accurate corrosion monitoring.

- Threaded Connecting Seat. This feature of the probe facilitates a secure and reliable connection to the pipeline system. The threads are precision-engineered to match industry-standard specifications, ensuring a tight fit that prevents any movement that could affect measurement accuracy or lead to wear and tear over time.

- High-Temperature Glass Sintering. At the interface end of the probe, high-temperature glass sintering works to seal and protect the internal components. This method of sealing is chosen for its superior durability and reliability under high temperature conditions, effectively insulating the internal elements from external environmental factors that could degrade the probe’s performance.

4. Functionality and Installation

Functionality:

The EMT-EP100 ER Corrosion Probe has a protective cap to shield the sensing element from damage and contamination, ensuring reliable corrosion monitoring. It seamlessly integrates with monitoring systems to provide real-time, accurate corrosion data, essential for pipeline integrity assessments.

Installation:

Installation of the EMT-EP100 is straightforward and designed to minimize system downtime. The probe attaches to a hollow plug using a probe nut and sealing ring, ensuring a secure, leak-proof connection. It is installed or retrieved using a retrieval tool and service valve, allowing operations to continue without the need for process shutdowns. This retrievable design facilitates easy maintenance, recalibration, or adjustment, enhancing system adaptability and operational efficiency without significant interruptions.

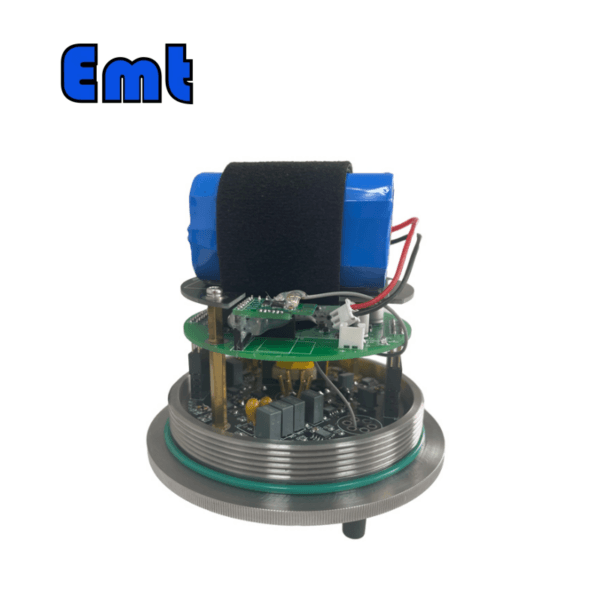

5. Additional Components

The probe adapter, essential for connecting the probe to a data collector. We must order it separately. This component is crucial for the functionality of the ER probe as it facilitates the transmission of corrosion data for analysis.

There are no reviews yet.