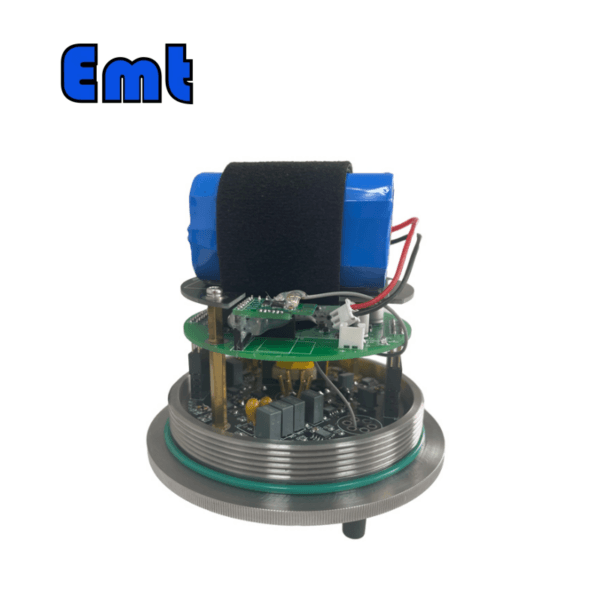

EMT ER Corrosion Probe

The EMT ER Corrosion Probe is a specialized device designed to monitor and assess the corrosion levels in pipeline systems. This probe plays a vital role in the maintenance and integrity of pipelines, particularly in industries such as oil and gas, chemical processing, and water treatment. Here are some key features and benefits of the EMT ER Corrosion Probe:

Real-Time Monitoring: The probe continuously measures corrosion rates, providing real-time data that helps operators make informed decisions regarding pipeline maintenance and safety.

Advanced Technology: Equipped with cutting-edge sensors, the EMT ER Corrosion Probe can detect even minor changes in corrosion levels. This sensitivity allows for early detection of potential issues, enabling timely interventions.

Its compatibility with existing systems makes it a flexible solution for operators.

Data Integration: The probe can integrate with monitoring systems to provide comprehensive data analysis. This feature allows for better tracking of corrosion trends over time, facilitating proactive maintenance strategies.

Cost-Effective Solution: The EMT ER Corrosion Probe enables early detection and monitoring of corrosion. This functionality helps reduce maintenance costs significantly. It also prevents costly repairs or replacements in the future.

Regulatory Compliance: The EMT ER Probe assists companies in meeting safety and environmental regulations. Using corrosion monitoring technology ensures compliance and reduces liability.

Selection Model of ER Corrosion Probe

| Model | |||||||||||||||

| ECP | Electrical Resistance Probes | ||||||||||||||

| -Code | Plug | ||||||||||||||

| Type | Material | Sealing material | |||||||||||||

| 0 | Not Required | 0 | Carbon steel | 0 | Not Required | ||||||||||

| 1 | Hollow plug | 1 | 316 stainless steel | 1 | Fluorine rubber sealing ring/PTFE main seal | ||||||||||

| 2 | 316L stainless steel | 2 | HNBR | ||||||||||||

| 3 | F51 duplex stainless steel | ||||||||||||||

| Pxxx | 4 | INCONEL nickel based alloy | |||||||||||||

| -Code | Temperature and pressure gauge assembly | ||||||||||||||

| Txxx | Connection size | Body material | Temperature and pressure gauge material | ||||||||||||

| 0 | Not Required | 0 | 304 stainless steel | 0 | Not Required | ||||||||||

| 1 | 1/2″ | 1 | 316 stainless steel | 1 | 304 stainless steel | ||||||||||

| 2 | 3/4″ | 2 | 316L stainless steel | 2 | 316 stainless steel | ||||||||||

| 3 | F51 duplex stainless steel | ||||||||||||||

| -Code | Probe assembly | ||||||||||||||

| Dxx | Connection size | Body material | Pipeline specification (x ″) | ||||||||||||

| 0 | Not Required | 0 | Carbon steel | Probe length varies with pipeline specifications | |||||||||||

| ‐Lx″ | 1 | 1/4″ | 1 | 304 stainless steel | |||||||||||

| 2 | 1/2″ | 2 | 304L stainless steel | ||||||||||||

| 3 | 316 stainless steel | ||||||||||||||

| 4 | 316L stainless steel | ||||||||||||||

| 5 | F51 duplex stainless steel | ||||||||||||||

| Example: ECP-P121-T021-D02-L6 “ | |||||||||||||||

There are no reviews yet.