![]()

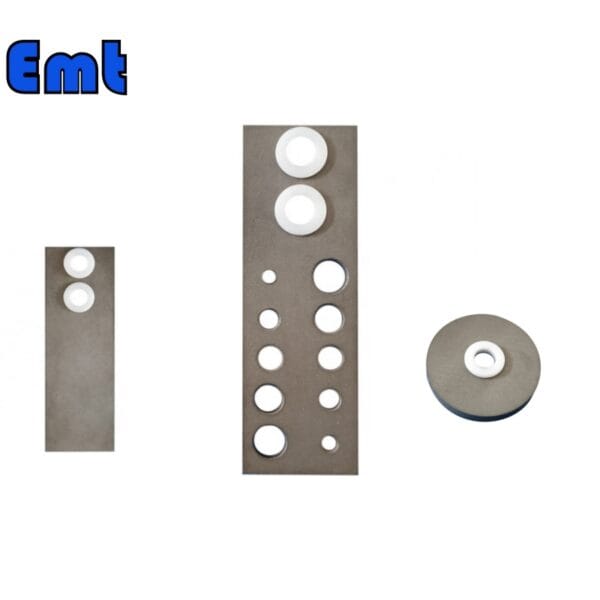

EMT Pipe Test Coupons Types

| Name | Strip Coupon | Multihole Strip Coupon | Disc Coupon |

| Applications | Commonly used for most evaluations. | Use with low-pressure access equipment or through narrow ports that a standard 3/4 inch wide coupon cannot pass. | These circular coupons work in multiple disc monitoring applications. |

| Size | 3”*3/4”*1/16” (76.2mm*19.0mm*3.2mm) | 3”*1/2”*1/16” (76.2mm*12.7mm*3.2) With mounting holes | Φ1.25”(31.8mm)Thickness 1/16”(3.2mm) |

Industrial Water Treatment Case Analysis

(coupon excessive corrosion problem)

1. Pipe Test Coupons are divided into type 1 and type 2, and their surface area are different. Corrosion hanging pieces are divided into copper, carbon steel, and stainless steel according to different materials.

2. The general test cycle of corrosion coupon is 1-3 months. The corrosion rate of carbon steel is 0.075mm/a after modification. Copper and stainless steel are 0.005mm/a. If it is a cleaning pre-film, there is another set of standards, welcome to leave a message to request. This standard is just a conversion of units. Because there is pickling, this standard will be much higher than the above standard.

3. It is necessary to know that every ten degrees higher water temperature. The corrosion rate of the hanging sheet is at least 30% higher, so the corrosion rate in summer is generally higher than in winter. If the surface of the hanging piece is a bit corroded, pitted, oxidized, etc.

Washing Pipe Test Coupons

4. The corrosion coupon cleaning process needs to be according to the national standard. The national standard requires 24 hours in advance to clean and dry. There is a lot of reality is the day of cleaning and drying, largely because the cleaning is not standard, the cleaning is not perfect, resulting in the second day before hanging in the coupon surface having oxidized traces, so special attention is necessary.

5. Pipe Test Coupons cleaning, drying, and weighing the whole process do not use hand direct contact, because the sweat in the hand very easily corrodes the coupon. When hanging in the rack of the simulated heat exchanger, it is best to order the materials from top to bottom as carbon steel, copper, and then stainless steel. You should slightly loosen the hanging plate when fixing it, allowing the hanging plate a small amplitude of shaking under a certain flow rate. This setup makes it less likely for mud to accumulate.

6. The normal coupon is hung in the water or the hanging rack of the simulated heat exchanger, and the flow rate needs to be higher than 0.6m/s, and the pipe path is better than 1m/s. On the one hand, to ensure a certain flow rate is very large, keep the surface of the hanging piece will not accumulate mud, and aggravate the corrosion. The second is to fully ensure the formation of the oxide film on the surface of the hanging piece, especially the open circulating water system, whose cool water tower and pool make it easier to accumulate mud, which requires a certain flow rate.

7. If there is adhesion mud or debris on the surface of the hanging piece, it is best to wash it off if the conditions are available. Otherwise, the change point is easy to corrode and extend along the direction of the water flow.

Online Corrosion Monitoring Technology

Developers have created on-site corrosion monitoring technology by combining laboratory corrosion tests and non-destructive testing technology of equipment with the actual conditions of production equipment and structures. Different methods provide different information parameters. They can be the determination of total corrosion, corrosion rate or corrosion state, the analysis of corrosion products or active substances, the detection of defects or changes in physical properties. But no matter what kind of method must have the characteristics of fast and lossless. This is also determined by the purpose and task of corrosion monitoring.

Pipe Test Coupons Method

In order to study the corrosion of a certain material in a specific environment, the sample is exposed to the environment for a period of time, and the change is measured.

Advantages: The earliest application of monitoring methods, the most widely used and one of the most reliable methods.

Disadvantages: can not get instantaneous corrosion information, not suitable for real-time monitoring.

Resistance probe

The principle of the resistance probe operates on the basis that corrosion reduces the probe’s cross-sectional area, thereby increasing its resistance. By accurately measuring the probe’s resistance at regular intervals, one can calculate the corrosion rate. Manufacturers typically make resistance probes into thin sheets, filaments, or tubes. This design reduces the cross-sectional area and increases the resistance value, enhancing sensitivity.

Advantages: simple production, low cost, strong applicability, no requirement for the medium, etc.

Disadvantages:

1. the reaction time is long – the instrument and recording system will react only when the corrosion accumulates to a certain extent.

2. not suitable for monitoring local corrosion.

There are no reviews yet.