The Metal Coupon method is one of the most commonly used corrosion monitoring methods in petroleum production. It is both direct and effective. As corrosion management requirements grow, there is an increasing need to analyze more than just the average corrosion rate of the coupons. We are now looking to more comprehensively mine the data properties of the coupons. You need to conduct analysis from multiple perspectives, including the mounting status of the coupon, the exposure environment, the morphology of the stripped metal, and the composition of any adherents. The microstructure of the corrosion is also crucial to examine. Through these comprehensive analyses, we can gain a deeper understanding of corrosion trends and more effectively identify potential risks.

Metal Coupon Types

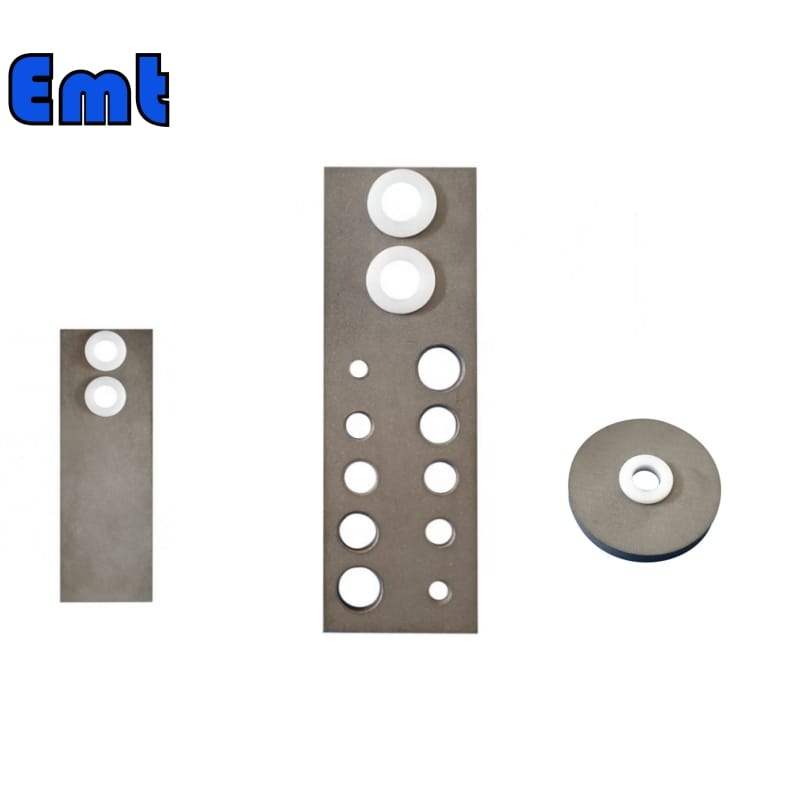

You determine the selection of the size and shape of metal coupons based on the type of hanger support, pipeline size, inlet direction, and monitoring purpose. Currently, in oil and gas fields, operators commonly use three types of coupons: ladder type bar coupons, porous coupons, and plate coupons.

Material

The material of the metal coupons typically matches the material of the system where they are installed to ensure consistency in corrosion monitoring.

EMT Metal Coupons Select Model

| Model | |||||||||||||

| CC | Corrosion Coupons | ||||||||||||

| -Code | Plug Body Assembly | ||||||||||||

| Pxxx | Type | Material | Sealing Material | ||||||||||

| 0 | No Request | 0 | CS | 0 | No Request | ||||||||

| 1 | Hollow Plug Body | 1 | 316SS | 1 | Viton O-Ring / PTFE Primary Packing | ||||||||

| 2 | Solid Plug Body | 2 | 316LSS | 2 | HNBR | ||||||||

| 3 | DUPLEX SS | ||||||||||||

| 4 | INCONEL | ||||||||||||

| Type of Coupon Holder | |||||||||||||

| SR | Fixed Coupon Holder for assembling rectangular coupon | ||||||||||||

| AR | Adjustable Coupon Holder for assembling rectangular coupon | ||||||||||||

| LR | Ladder Coupon Holder for assembling rectangular coupon | ||||||||||||

| SC | Fixed Coupon Holder for assembling circular coupon | ||||||||||||

| AC | Adjustable Coupon Holder for assembling circular coupon | ||||||||||||

| -Pipe Size | |||||||||||||

| x | Pipe Size in inch | ||||||||||||

| – Coupon Size | |||||||||||||

| A×B×C | Coupon Size in inch or mm | ||||||||||||

| – Coupon Material | |||||||||||||

| x | Grade | ||||||||||||

| -Finishing of Coupon | |||||||||||||

| 0 | Mill | ||||||||||||

| 1 | Glass Bead | ||||||||||||

| – Isolation Gasket | |||||||||||||

| 0 | No Gasket | ||||||||||||

| 1 | Nylon Gasket | ||||||||||||

| 2 | PTFE Gasket | ||||||||||||

| For Example CC-P221-SR-6″-3″×1/2″×1/8″-MS1018-0-2 CC: Corrosion Coupon | |||||||||||||

| P221: Solid Plug Body in 316LSS Viton O-Ring and PTFE Primary Packing | |||||||||||||

| SR-6″:Fixed Coupon Holder for assembling rectangular coupons and for 6″pipe | |||||||||||||

| 3″×1/2″×1/8″: Coupon Size MS1018: Coupon Material | |||||||||||||

| 0: Finishing of Coupon is Mill 2: Material of Isolation Gasket is PTFE | |||||||||||||

Install Position

For more accurate corrosion measurement, you should install coupons where corrosion is active or most likely to occur. It is generally recommended to position the coupon at the 12 o’clock position on the pipeline. You should also consider installing coupons in other particularly corrosion-prone areas, such as stagnant water zones, high-velocity and impact zones, low points in pipelines, and liquid/gas transition areas.

To obtain the most accurate corrosion data, it is crucial to install the coupons in areas where corrosion is either occurring or is most likely to occur. Optimal installation points within a pipeline might include:

The 12 o’clock position for general monitoring.

Stagnant water zones where corrosion could be exacerbated.

High-velocity zones which might experience increased erosion-corrosion.

Low points in the pipeline where moisture and sediments may accumulate.

Areas around liquid/gas interfaces which are susceptible to different types of corrosion.

Install Method

There are two prevalent methods for mounting corrosion coupons in oil and gas fields:

A 2-inch system used for high-pressure systems.

A retractable 1-inch system used for low-pressure systems.

Types of Metal Coupons

The selection of metal coupons involves considering several factors, such as the type of hanger support, pipeline size, inlet direction, and the specific goals of the monitoring activity. Commonly used types of coupons in oil and gas fields include:

Ladder Type Bar Coupons: Ideal for spanning across larger pipeline diameters.

Porous Coupons: Useful for detailed analysis of localized corrosion.

Plate Coupons: Typically used for general corrosion monitoring over a flat surface.

| Name | Strip Coupon | Multihole Strip Coupon | Disc Coupon |

| Applications | Commonly used for most evaluations. | Use with low-pressure access equipment or through narrow ports that a standard 3/4 inch wide coupon cannot pass. | These circular coupons work in multiple disc monitoring applications. |

| Size | 3”*3/4”*1/16” (76.2mm*19.0mm*3.2mm) | 3”*1/2”*1/16” (76.2mm*12.7mm*3.2) With mounting holes | Φ1.25”(31.8mm)Thickness 1/16”(3.2mm) |

Something About Pipeline Corrosion

Pipeline corrosion is a significant concern in industries such as oil and gas, water distribution, and chemical processing. It occurs when pipelines are exposed to corrosive environments, leading to the deterioration of the material and eventual failure of the pipeline. Factors influencing corrosion include the material composition of the pipeline, the presence of corrosive chemicals, the temperature and pressure of the transported substances, and environmental conditions such as soil composition and moisture levels.

Industries employ various methods to mitigate corrosion. They use corrosion-resistant materials and apply protective coatings. They also implement cathodic protection by applying an electrical charge. Regular monitoring occurs with corrosion coupons and probes. The consequences of unchecked pipeline corrosion can be severe, including leaks, spills, and catastrophic failures leading to environmental damage, financial loss, and safety hazards. Effective management and preventive strategies are crucial to maintaining the integrity and longevity of pipeline systems.

There are no reviews yet.