Each EMT CIPC Corrosion Probe is sold as a single unit. The typical package size is 10 x 4 x 2 cm, although this may vary with different products. Each package weighs 1 kilogram. For payment, customers can use TT (Telegraphic Transfer) or LC (Letter of Credit). The warranty covers the probe for 1.5 years, ensuring reliable performance.

Additionally, EMT offers customized support options. Customers can opt for OEM (Original Equipment Manufacturer) or ODM (Original Design Manufacturer) services. These services allow customization of the probe to meet specific industrial requirements. This flexibility is ideal for industries needing precise adaptations for unique operational conditions.

Parameters of EMT CIPC Corrosion Probe

The EMT CIPC Corrosion Probe is a cutting-edge tool designed for precise monitoring in high-pressure environments. The probe features robust construction with Stainless Steel 316 and L DUPLEX SS materials. There are two types of EMT corrosion probe connections: weld connection and flange connection. It measures 3″ x 3/4″ x 1/16″ and can handle temperatures from -20℃ to 200℃. It also withstands pressures up to 26 MPa. This makes it perfect for high-pressure hydrogen applications. The probe boasts high accuracy while remaining cost-effective. It comes with ISO 9001 certification, ensuring top quality. Additional features include a variety of sealing materials like Teflon and Viton O-rings. It offers customizable connection options such as 2″ welded or ANSI flange fittings. The protective PTFE coating and durable flange ensure long-lasting performance. This probe meets a wide range of industrial needs, making it a versatile choice for your operations.

| Product Specifications | |

| Brand Name: | EMT Pigging |

| Product Name: | Resistance Probe |

| Material: | Stainless Steel 316, L DUPLEX SS |

| Size: | 3″ x 3/4″ x 1/16″ |

| Design Temperature: | -20℃ to 200℃ |

| Design Pressure: | 0 to 26 MPa |

| Keyword: | High-Pressure Hydrogen Probe |

| Feature: | High Accuracy and Low Cost |

| Certification: | ISO 9001 |

| Additional Technical Details | |

| Metal Material: | Stainless Steel 316, L DUPLEX SS |

| Sealing Material: | Teflon/Fluororubber/Viton O-ring |

| Access Fitting Body: | 2”welded; 2”ANSI Flange (suffix “pressure rating & pipe size & sealing type can meet customer needs) |

| Protective Cover: | PTFE Coated |

| Flange Size: | ANSI 2″RF (or RJ) |

| Body Material: | CS,304SS,316SS,316LSS,DUPLEX SS |

| Nozzle Material: | 304SS,316SS,316LSS,DUPLEX SS |

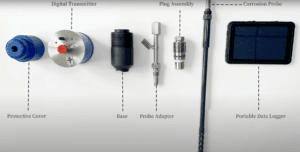

Components of EMT New Type Corrosion Probe

| Components | |

| 1 | Protective Cover |

| 2 | Digital Transmitter |

| 3 | Base |

| r | Probe Adapter |

| 5 | Plug Assembly |

| 6 | Corrosion Probe |

| 7 | Portable Data Logger |

The EMT CIPC Corrosion Probe consists of several key components, each integral to its operation. Starting with the protective cover, this component shields the internal parts from environmental hazards and physical damage, ensuring the probe’s durability. Next, the digital transmitter processes and sends data from the probe to the monitoring system, allowing for real-time corrosion monitoring.

Moving on, the base of the probe provides a stable platform and houses the primary connections to the probe adapter. This adapter is crucial as it facilitates the attachment of the probe to different systems, making installation flexible and straightforward. Additionally, the plug assembly is essential for securing the probe in place and ensuring a tight seal to prevent leaks and maintain accurate readings.

The corrosion probe itself is the heart of the system. It directly contacts the materials or environments being monitored for corrosion, making it critical for gathering precise data. This component is highly sensitive and designed to detect even minor changes in corrosion levels.

Finally, the portable data logger is a key feature that offers versatility. It allows for the collection and storage of data on-site, which is particularly useful in locations where remote monitoring is not feasible. This data can later be analyzed to assess corrosion trends and maintenance needs.

Together, these components form a comprehensive system designed for effective corrosion monitoring in a variety of industrial settings. Whether used in oil and gas pipelines, chemical plants, or water treatment facilities, the EMT CIPC Corrosion Probe delivers reliable performance and enhances the safety and longevity of infrastructure by providing critical data on corrosion rates and patterns. This system not only helps in maintaining the integrity of industrial equipment but also aids in planning preventive maintenance schedules to avoid costly repairs and downtime.

Specifications

| Technical specifications | |

| Output signal | Wired form: RS-485 signal; |

| Wireless form: LORA, 4G/5G wireless network signal | |

| Power supply voltage | 9-36VDC |

| Rated operating voltage | 9VDC |

| Meter power consumption | 5.4W (Wired) |

| Linear | 0.0015% non-linear |

| Resolution | 17 bit |

| B | 25.6 mV |

| Accuracy | ±0.2% F.S (full scale) |

| Corrosion rate range | When the electrode area is 1cm², the measurement range is 4X10-4~10mm/a |

| Working and storage conditions | |

| Operating temperature | -40~70℃ |

| Storage temperature | -40~85℃ |

| Structural parameter | |

| Protection level | IP66 |

| Shell material | Cast aluminum or PVC, aviation aluminum, stainless steel can be customized |

| Process interface | 7/8-20UNEF (Insert probe) |

| Electrical connection | M20*1.5mm |

| Access cable Model | RVVP 2*1.5mm² (minimum application standard) |

| Installation | The probe is installed directly on the pipeline, and the transmitter can be installed in one piece or separately through the cable |

| Weight | 500g |

| Split type accessory | Interface: MS-14-6S double female head |

| Split connection cable | Cable length: 1-3 meters can be customized |

| Authentication | |

| Hazardous area certification | EX-d IIC T4 Gb |

There are no reviews yet.