Introduction to Corrosion Coupon

Corrosion Coupon helps detect corrosion in water systems over time. Initially weighed without corrosion, their weight is compared after exposure periods of 60, 90, or 120 days. Available in various materials, they assess different systems. The technique used with these coupons significantly impacts their effectiveness.

Hang corrosion plates in test containers, heat exchangers, or pipes to determine corrosion. Use standard metal test plates for evaluation. Detect the corrosion status of the cooling water system. Place pre-treated metal in the test system. Leave it for 30 to 90 days, then remove it. Observe, clean, and weigh the metal to assess corrosion. Determine weight loss, corrosion type, and pitting depth. Data also depends on surface treatment, placement, exposure time, and metallurgical method.

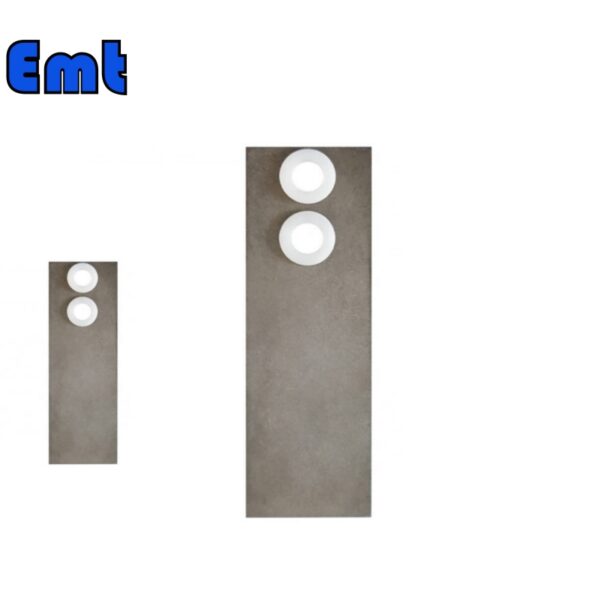

| Name | Strip Coupon | Multihole Strip Coupon | Disc Coupon |

|  |  | |

| Applications | Commonly used for most evaluations. | Use with low-pressure access equipment or through narrow ports that a standard 3/4 inch wide coupon cannot pass. | These circular coupons work in multiple disc monitoring applications. |

| Size | 3”*3/4”*1/16” | 3”*1/2”*1/16” | Φ1.25”(31.8mm)Thickness 1/16”(3.2mm) |

| (76.2mm*19.0mm*3.2mm) | (76.2mm*12.7mm*3.2) | With 2 mounting holes. | |

| With mounting holes. |

Causes of Natural Gas Pipeline Corrosion:

Chemical corrosion occurs when oxygen or oxidants react with the pipeline, forming acids that corrode it.

Biological corrosion happens when bacteria and fungi attach to the pipeline, causing metal corrosion.

Electrochemical corrosion occurs when electrolytes like moist soil cause reactions that destabilize the pipeline.

Anti-Corrosion Measures:

Apply anti-corrosion coatings like polyethylene or epoxy to the pipeline to prevent chemical and biological corrosion.

Install sacrificial anodes on the pipeline for cathodic protection to prevent electrochemical corrosion.

Use interference suppression measures like shielding to prevent microbial corrosion around the pipeline.

Line the pipeline interior with corrosion-resistant materials like ceramic to enhance durability.

Install auxiliary devices like drain boards to increase resistance and reduce corrosion currents in the pipeline.

Selection Model of Corrosion Coupon

| Model | ||||||

| EMT-CIPA | Access Fitting Body of Corrosion Coupon | |||||

| – The material of Access Fitting Body | ||||||

| 0 | CS | |||||

| 1 | 316SS | |||||

| 2 | 316LSS | |||||

| 3 | DUPLEX SS | |||||

| The Type of Access Fitting Body | ||||||

| B | 2″Welded(suffix “pressure rating” can be added to B) | |||||

| F | 2″ANSI Flange(suffix “pressure rating & sealing type” can be added to F) | |||||

| -Tee Size- pressure rating & sealing type if the flanged end | ||||||

| 0 | No Tee | |||||

| 1 | 1/4″NPT(F)Tee | |||||

| 2 | 1/2″NPT(F)Tee | |||||

| 3 | 3/4″NPT(F)Tee | |||||

| 4 | 1″NPT(F)Tee | |||||

| 5 | Hole for 1/4″SWN Flange | |||||

| 6 | Hole for 1/2″SWN Flange | |||||

| 7 | Hole for 3/4″SWN Flange | |||||

| 8 | Hole for 1″SWN Flange | |||||

| -Protective Cover Type/ Material | ||||||

| 0 | No Protective Cover | Material | ||||

| 1 | Without hole | CS or 0 | ||||

| 2 | With hole | SS or 1 | ||||

| 3 | Bleed Valve | DSS or 3 | ||||

| 4 | Bleed Valve, & Pressure Gauge | |||||

| For Example, EMT-CIPA-0F600#RF-2-1/CS shows 2″ANSI 600#RF Flange Access Fitting Body in CS, 1/2″NPT(F)Tee, Protective Cover in CS without hole | ||||||

| 0F600#RF: 0F_ Access Fitting Body is Flanged in CS, 600#RF _Size is 2″ANSI 600#RF, | ||||||

| 2:Tee size is 1/2NPT(F) | ||||||

| 1: Protective cover type is without a hole | ||||||

| /CS: Protective cove material in CS | ||||||

The Standard for Corrosion Test by Hanging Plate Method

The hanging corrosion test is a commonly used method to test the corrosion performance of metals. By hanging Corrosion Coupon sample pieces on the surface of metals and exposing them to corrosive media, the corrosion performance of metals in a specific environment can be evaluated. This paper will introduce the standard operation flow and precautions of the corrosion experiment of the hanging film method so that the experimentalists can carry out the experiment accurately and standardized.

Experiment preparation.

Before carrying out the corrosion test of the hanging plate method, it is necessary to prepare the sample piece and the corrosion medium. The selection of sample pieces should meet the requirements of the experiment, usually thin or sheet samples of metal materials.

The choice of corrosive medium should meet the experimental requirements, the common corrosive medium includes brine, acidic solution, etc. When selecting the corrosion medium, it is necessary to consider the corrosion properties of the actual use environment to simulate the real corrosion situation.

Experimental operation.

Hang the sample piece in the test equipment and expose it to a corrosive medium. During the experiment, it is necessary to observe the corrosion of the sample piece regularly and record the corrosion rate, corrosion degree, and other data. At the same time, it is necessary to pay attention to the operation specifications of the experimental equipment to ensure the safety and accuracy of the experimental process.

Data processing

After the experiment, it is necessary to process and analyze the experimental data. According to the corrosion condition of the sample piece, the corrosion rate and corrosion depth can be calculated to evaluate the corrosion performance of the metal material. At the same time, it is necessary to summarize the operation records and observation results during the experiment and write the experiment report.

Precautions.

When carrying out the corrosion test of the hanging chip method, the following points need to be noted:

The experimental operation should be standardized and follow the standard operating procedure to ensure the accuracy and reliability of the experimental results. The selection and use of experimental equipment should meet the requirements of the experiment to ensure the safety and stability of the experiment process

There are no reviews yet.