The EMT-CIPA Metal Corrosion Coupon is specifically designed to monitor corrosion rates within pipes or containers by measuring the annual corrosion rate of a sample, or coupon. Consequently, by analyzing these rates, you can accurately determine the corrosion rate of your entire piping system. These coupons are invaluable, as they provide critical insights into the expected lifespan of the material. Furthermore, a corrosion coupon serves as a practical tool to quantitatively estimate the corrosion rates in a functioning system. Typically, the materials used for corrosion coupons are identical to those used in the pipeline, ensuring consistency in monitoring and results.

Metal Corrosion Coupon Types

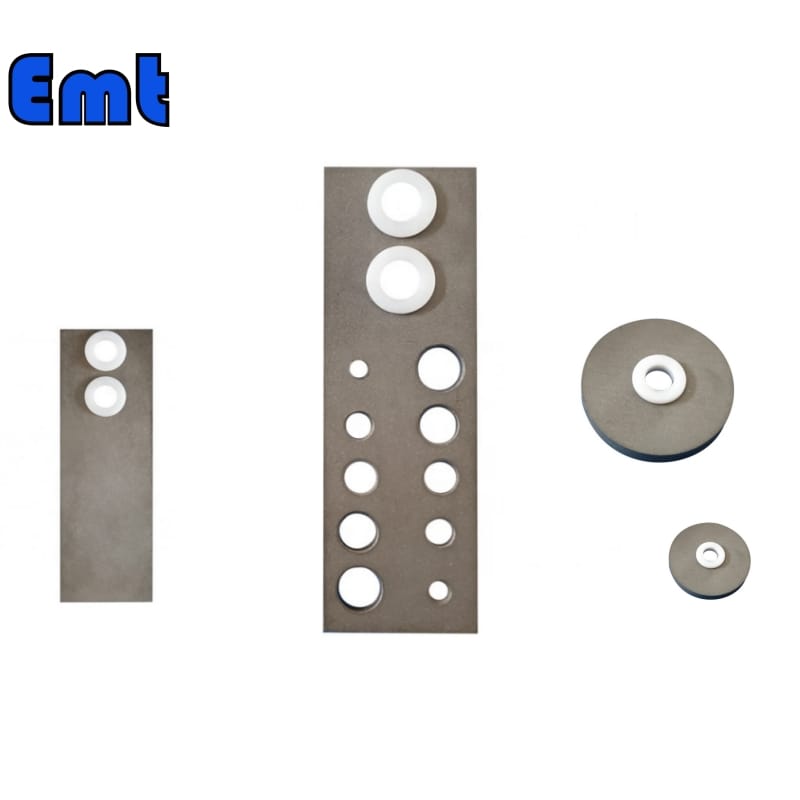

Our EMT company provides three types of corrosion coupons:

| Name | Strip Coupon | Multihole Strip Coupon | Disc Coupon |

| Applications | Commonly used for most evaluations. | Use with low-pressure access equipment or through narrow ports that a standard 3/4 inch wide coupon cannot pass. | These circular coupons work in multiple disc monitoring applications. |

| Size | 3”*3/4”*1/16” (76.2mm*19.0mm*3.2mm) | 3”*1/2”*1/16” (76.2mm*12.7mm*3.2) With mounting holes | Φ1.25”(31.8mm)Thickness 1/16”(3.2mm) |

Metal Corrosion Coupons in Corrosion Monitoring

Metal corrosion coupons are essential tools in the field of corrosion monitoring, providing a cost-effective and straightforward method for assessing the rate and type of corrosion within an industrial system such as pipelines, tanks, and processing equipment.

Functionality of Metal Corrosion Coupons

Corrosion coupons are small metal samples that are representative of the system’s material. Initially, they are installed directly into the environment where corrosion is expected to occur. Over a designated period, these coupons undergo the same corrosive processes as the system itself. Subsequently, after this exposure period, the coupons are removed and analyzed. This analysis involves measuring the loss in mass, surface degradation, and pitting depth, which together indicate the severity and type of corrosion.

Key Benefits of Using Metal Corrosion Coupons

Simplicity: The method is simple to implement and understand, making it accessible for routine monitoring.

Cost-Effectiveness: Metal coupons are inexpensive relative to other corrosion monitoring technologies.

Direct Measurement: They provide direct empirical evidence of the corrosion rate and characteristics.

Material Specific: Coupons can be made from the same material as the system being monitored, ensuring relevant results.

Implementation of Metal Corrosion Coupons

To ensure effective monitoring, coupons must be placed strategically within the system:

Placement: Coupons are typically installed in areas known for higher corrosion risk or where corrosion monitoring is critical. This can include high moisture areas, near chemical injections, or in flow disturbances.

Duration: The exposure period can vary based on the expected corrosion rates and monitoring needs, ranging from a few weeks to several months.

Analysis: After retrieval, we clean the coupons of any corrosion products and measure their weight loss to calculate the corrosion rate. We may also conduct additional microscopic examinations to assess the surface morphology and deeper structural impacts.

Challenges and Considerations

While metal corrosion coupons provide valuable insights, they also have limitations:

Snapshot Data: Coupons offer a snapshot of corrosion at specific points in time, not continuous monitoring.

Physical Limitations: Coupons only reflect the conditions at their specific location and may not capture corrosion variability across a large system.

Handling and Analysis: Proper handling and accurate analysis of the coupons are crucial to ensure valid data.

In conclusion, metal corrosion coupons are a foundational element of corrosion monitoring strategies in various industries. They provide a practical means of evaluating material degradation and help guide maintenance decisions, ultimately extending the life and safety of industrial systems.

Selection Model of EMT Metal Corrosion Coupon

The following is our EMT Metal Corrosion Coupon selection model:

| Model | |||||||||||||

| CC | Corrosion Coupons | ||||||||||||

| -Code | Plug Body Assembly | ||||||||||||

| Pxxx | Type | Material | Sealing Material | ||||||||||

| 0 | No Request | 0 | CS | 0 | No Request | ||||||||

| 1 | Hollow Plug Body | 1 | 316SS | 1 | Viton O-Ring / PTFE Primary Packing | ||||||||

| 2 | Solid Plug Body | 2 | 316LSS | 2 | HNBR | ||||||||

| 3 | DUPLEX SS | ||||||||||||

| 4 | INCONEL | ||||||||||||

| Type of Coupon Holder | |||||||||||||

| SR | Fixed Coupon Holder for assembling rectangular coupon | ||||||||||||

| AR | Adjustable Coupon Holder for assembling rectangular coupon | ||||||||||||

| LR | Ladder Coupon Holder for assembling rectangular coupon | ||||||||||||

| SC | Fixed Coupon Holder for assembling circular coupon | ||||||||||||

| AC | Adjustable Coupon Holder for assembling circular coupon | ||||||||||||

| -Pipe Size | |||||||||||||

| x | Pipe Size in inch | ||||||||||||

| – Coupon Size | |||||||||||||

| A×B×C | Coupon Size in inch or mm | ||||||||||||

| – Coupon Material | |||||||||||||

| x | Grade | ||||||||||||

| -Finishing of Coupon | |||||||||||||

| 0 | Mill | ||||||||||||

| 1 | Glass Bead | ||||||||||||

| – Isolation Gasket | |||||||||||||

| 0 | No Gasket | ||||||||||||

| 1 | Nylon Gasket | ||||||||||||

| 2 | PTFE Gasket | ||||||||||||

| For Example CC-P221-SR-6″-3″×1/2″×1/8″-MS1018-0-2 CC: Corrosion Coupon | |||||||||||||

| P221: Solid Plug Body in 316LSS Viton O-Ring and PTFE Primary Packing | |||||||||||||

| SR-6″:Fixed Coupon Holder for assembling rectangular coupons and for 6″pipe | |||||||||||||

| 3″×1/2″×1/8″: Coupon Size MS1018: Coupon Material | |||||||||||||

| 0: Finishing of Coupon is Mill 2: Material of Isolation Gasket is PTFE | |||||||||||||

There are no reviews yet.