The ECP series Electrical Resistance Probe is a specialized instrument designed to monitor and assess corrosion levels within industrial systems by detecting changes in the resistance of its sensing elements when exposed to corrosive environments. This probe is an essential tool for the early detection of corrosion. Which is critical for preventing equipment failure and ensuring safe production processes. Capable of handling pressures up to 26 MPa, it is suitable for a broad range of industrial applications.

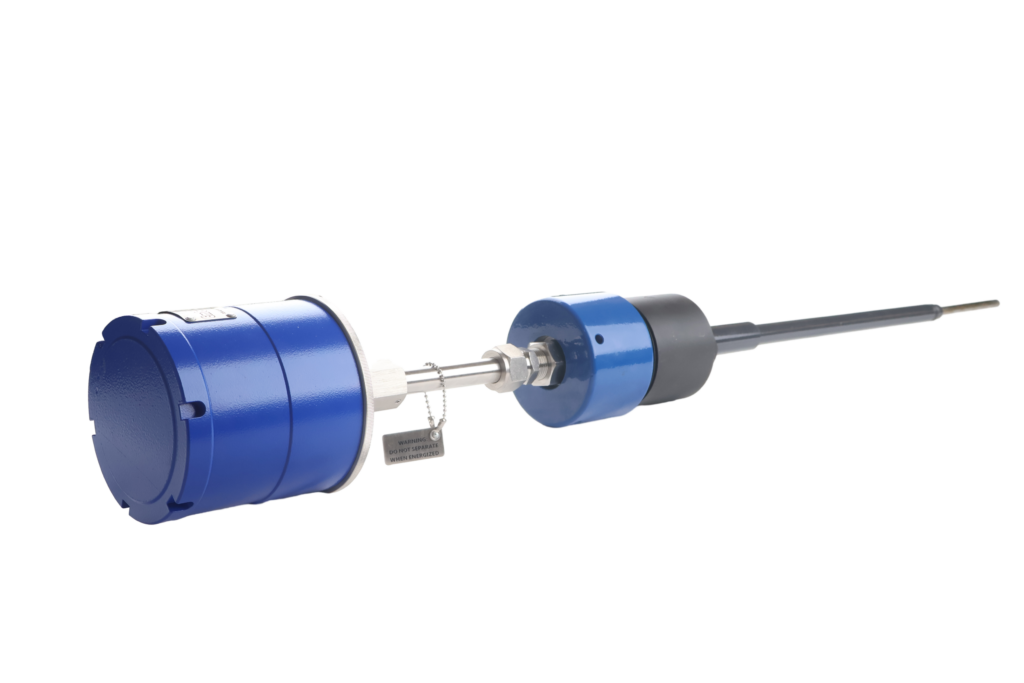

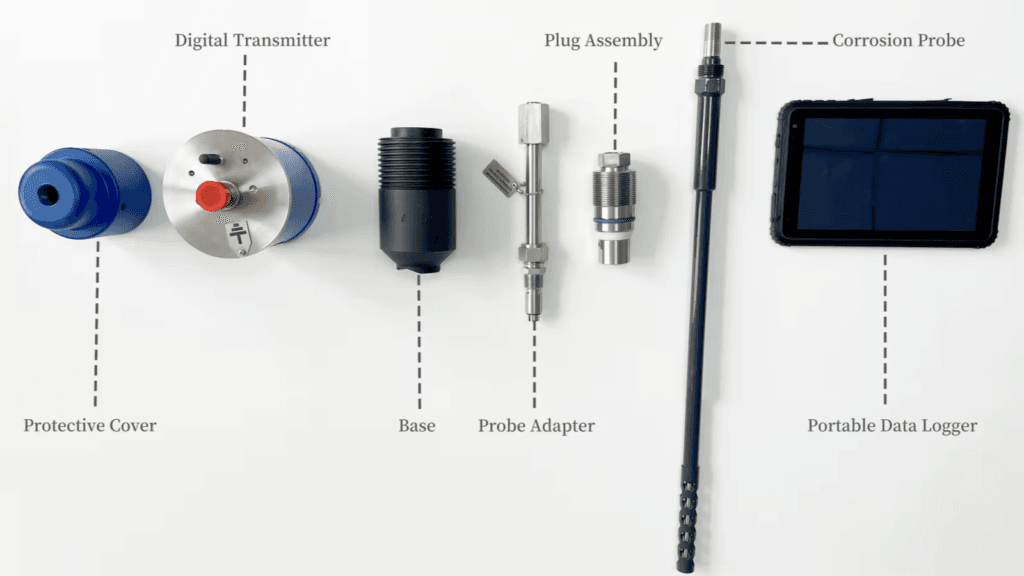

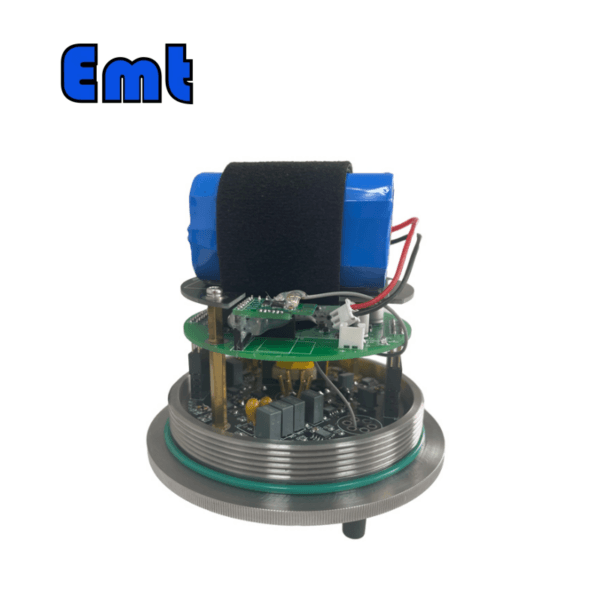

1. Design and Components of the ECP Series Electrical Resistance Probe

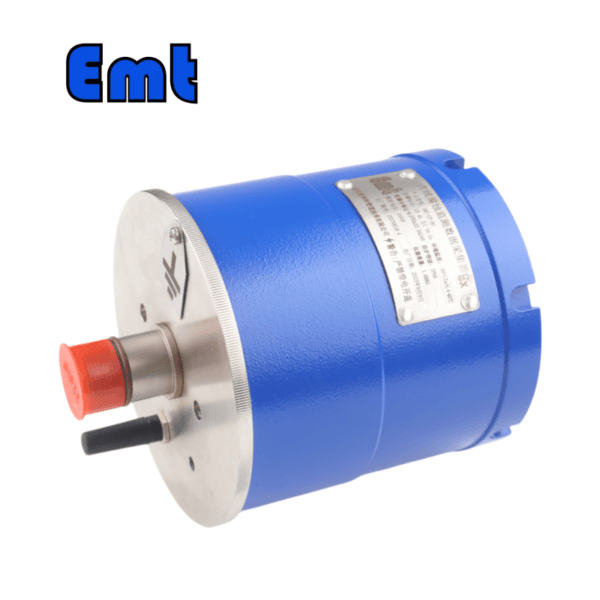

Protective Cover

The protective cover is a crucial component of the ECP series probe assembly. It serves as a physical barrier, protecting the sensitive internal components of the probe from environmental contaminants, mechanical impacts, and chemical exposures that could otherwise compromise its function and longevity. Typically constructed from the same high-grade materials as the probe body. Such as 316L stainless steel, the cover is engineered to withstand the harsh conditions often found in industrial settings while maintaining its structural integrity.

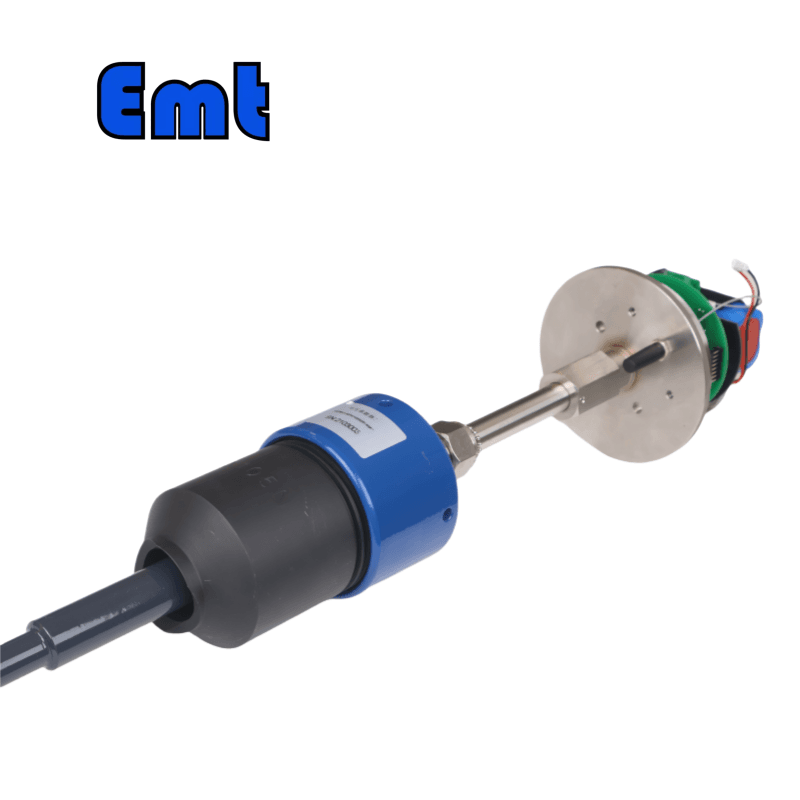

Resistance Probe

The resistance probe is at the core of the ECP series’ functionality. It is specifically to detect changes in resistance that occur as a result of corrosive processes affecting the metal surfaces it monitors. This probe is available in two configurations:

- Cylindrical Resistance Probe:

This form factor is suited for general-purpose applications where uniform exposure to the corrosive media can be expected. Its cylindrical shape allows for easy installation and an even interface with the surrounding environment, facilitating consistent readings.

- Sheet (Needle) Resistance Probe:

This variant is thinner and more focused, ideal for applications requiring precise detection in narrow or confined spaces. The needle-like design provides the sensitivity needed for pinpointing specific areas prone to corrosion, allowing for targeted monitoring and detailed analysis of localized corrosion activity.

2. Temperature and Pressure Gauge Component

Integrated directly within the probe assembly, this component is vital for monitoring the operational conditions around the probe. The gauge is a hollow device that measures both the temperature and pressure of the medium in which the probe operates. These measurements are essential because temperature and pressure can significantly influence corrosion rates and. Consequently, the resistance changes detected by the probe. By monitoring these parameters, the ECP series ensures that the data collected on resistance changes are accurately contextualized with environmental conditions, leading to more reliable and actionable insights.

3. Materials and Construction:

- Metal Materials:

The probe and its installation fixtures are constructed from 316L stainless steel and F51 duplex stainless steel. These materials are chosen for their superior strength and excellent corrosion resistance, making them ideal for harsh industrial environments.

- Sealing Materials:

Teflon and fluororubber work for their outstanding sealing properties and chemical resistance, ensuring the probe maintains its integrity between -20°C and 200°C and withstands full operational pressures of 0-26 MPa.

4. Installation and Operation:

The electrical resistance probe can be installed into the pipeline system via welding or flange connections, depending on the specific requirements and infrastructure. The flange option utilizes an ANSI 2″ RF (or RJ) standard, made from carbon steel, 316L stainless steel, or duplex stainless steel. Which matches the robustness of the probe and allows for easier maintenance and inspection access.

5. Functionality and Application

Functionality

The ECP series probe functions primarily through the principle of electrical resistance measurement to monitor corrosion. Here’s how it works:

- Resistance Measurement:

The probe contains metallic elements whose electrical resistance is known to vary with changes in their chemical composition and physical structure. Which can occur due to corrosion. When these elements come into contact with corrosive substances, corrosion products (such as rust or other oxides) start to form on their surface, altering their resistance.

- Signal Processing:

The operator connect the probe to a monitoring system that continuously records the resistance levels. This system can detect even minor changes in resistance that indicate the early stages of corrosion. Then advanced signal processing techniques are employed to distinguish these changes from normal fluctuations in environmental conditions.

- Data Interpretation:

The data on resistance changes are analyzed using algorithms that correlate specific resistance values with levels of corrosion. So this analysis helps to accurately gauge the severity and rate of corrosion over time.

Application

The ECP series Electrical Resistance Probe finds applications in a variety of industries and settings where corrosion can pose significant operational and safety risks. Some of these applications include:

- Oil and Gas Pipelines: In pipelines, early detection of corrosion can prevent leaks and ruptures that could lead to environmental disasters and costly shutdowns. The probe can monitor sections of pipelines that are susceptible to corrosion due to factors like moisture, salinity, or contact with corrosive chemicals.

- Chemical Processing Plants: These facilities often deal with aggressive chemicals that can degrade equipment. Installing ECP probes in critical areas allows for continuous monitoring and maintenance planning that can preempt equipment failures.

- Water Treatment Systems: Corrosion in water treatment systems can lead to contamination and system inefficiency. The probes can also help in monitoring the condition of tanks and pipes. It ensures the integrity of the water treatment process.

- Marine Structures: Saltwater environments are highly corrosive. ECP probes can work to monitor the degradation of ships, offshore platforms, and other marine installations to plan maintenance before significant corrosion compromises structural integrity.

There are no reviews yet.