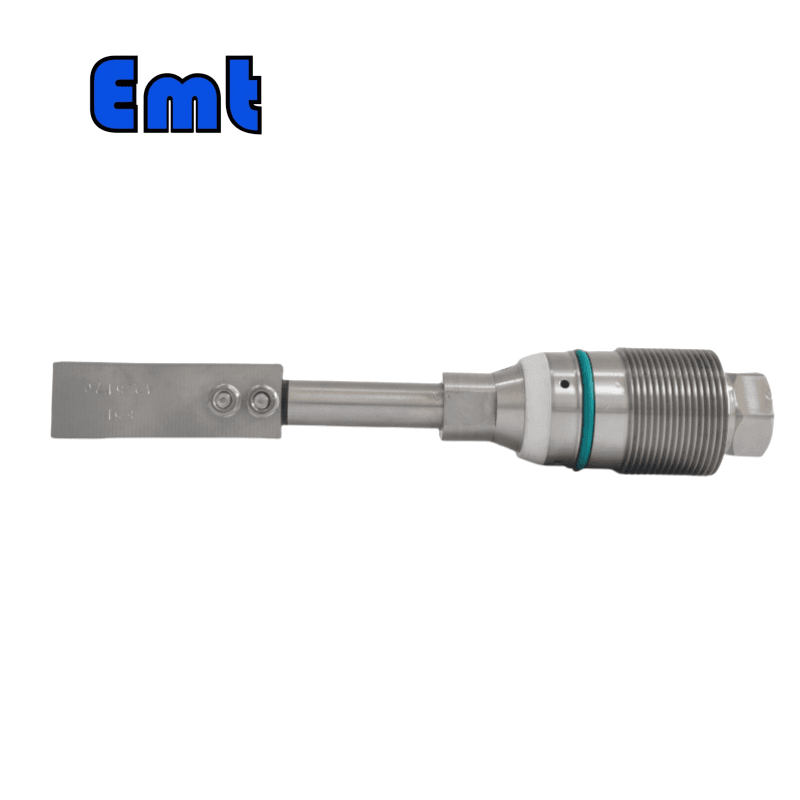

Corrosion monitoring is a critical aspect of maintaining the integrity and longevity of pipelines and storage facilities in various industries. Cupon De Corrosion EMT-CC are specifically designed for this task, providing a direct measure of the corrosion rates within a system. These coupons, when inserted into a pipeline or container, expose a controlled surface area to the environment within, and the subsequent corrosion that occurs on these coupons can be analyzed to predict the system’s overall corrosion behavior.

1. Description of Cupon De Corrosion EMT-CC

The available materials include:

- Stainless Steel 304 and 316: Known for their corrosion resistance and strength, suitable for a wide range of applications.

- DSS F51: A duplex stainless steel that provides even greater strength and corrosion resistance.

- Carbon Steel A105N: Commonly used in less corrosive environments where cost is a concern.

- Inconel 625: An alloy known for its high strength and outstanding corrosion resistance, particularly in extreme environments such as marine or acidic settings.

These corrosion coupons offer a straightforward yet effective method of monitoring, characterized by features such as:

- Easy Operating: Designed for simplicity, allowing for quick installation and retrieval without the need for specialized tools.

- High Accuracy and Long Life: Ensures precise corrosion rate measurements over an extended period.

- High Efficiency and Low Cost: Provides cost-effective corrosion monitoring without compromising on performance.

2. Additional Features and Advantages

EMT-Cc Cupon De Corrosion are engineered to provide several key benefits that enhance their functionality and appeal to industry professionals. Below is an expanded discussion of these features, explaining how they contribute to efficient and reliable corrosion monitoring.

Lightweight and Flexible

The physical design of Cupon De Corrosion EMT-CC emphasizes ease of handling and versatility:

- Ease of Handling: The lightweight nature of the coupons ensures that they can be easily transported and handled by technicians, reducing physical strain and the risk of accidental drops that might damage the coupons.

- Versatility in Installation: Flexibility is another crucial aspect, as it allows the coupons to be installed in a variety of pipeline configurations and environments. Whether the pipeline is straight, curved, or vertical, the flexible design of these coupons means they can be adapted to fit without requiring custom-made solutions.

Excellent Injection and Retrieval Efficiency

The design and operational features of the coupons support efficient processes for both insertion and removal:

- Minimized Downtime. The efficient injection and retrieval mechanism of the coupons means that their installation and removal can be completed quickly during scheduled maintenance or inspection windows. This efficiency is critical in minimizing operational downtime, which is especially valuable in high-throughput industries where every minute of operation counts.

- Reduced Risk of Coupon Loss. The mechanism used for inserting and retrieving the coupons is designed to securely hold them in place during operation and allow for easy access when they need to be removed. This reduces the likelihood of coupons getting stuck or lost within the pipeline, which can lead to additional operational disruptions and costs.

Accurate Location Tracking

The ability to precisely locate corrosion coupons within a system is vital for accurate data collection and analysis:

- Consistency in Data Collection. By ensuring that each coupon can be placed and retrieved from the exact same location, Cupon De Corrosion EMT-CC provide consistent environmental exposure and, consequently, consistent data on corrosion rates. This consistency is crucial when comparing data over time to monitor changes in corrosion rates or to assess the effectiveness of corrosion inhibitors.

- Enhanced Data Reliability. Accurate location tracking also enhances the reliability of the data collected. Knowing the exact position of each coupon in relation to the pipeline’s layout helps in diagnosing specific areas that may be experiencing higher rates of corrosion. This targeted data is valuable for making informed decisions about where to focus maintenance efforts and how to optimize material selection for different sections of the pipeline.

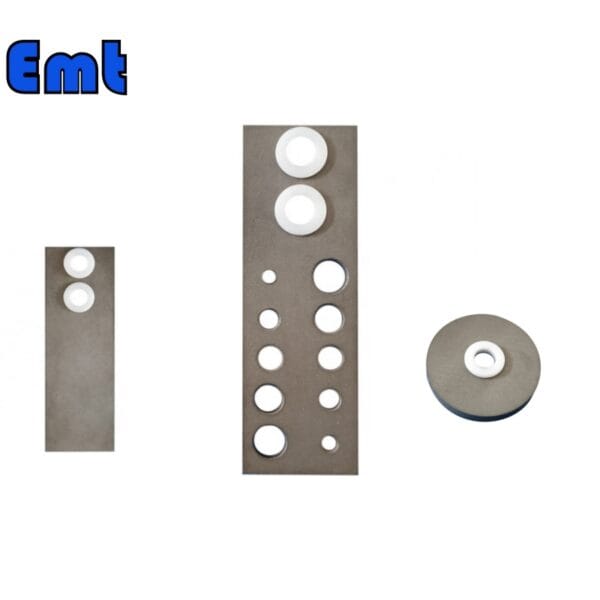

3. Insulation and Temperature Adaptability

The Cupon De Corrosion come standard with Delrin insulation, rated for temperatures up to 200°F (93°C). For applications requiring higher temperature resistance, alternative insulation materials are available:

- Teflon: Offers temperature resistance up to 500°F (260°C).

- Rulon: Capable of withstanding up to 550°F (288°C).

- Ceramic: Suitable for extremely high-temperature environments up to 1472°F (800°C).

4. Application and Benefits

Understanding Material Degradation

- Direct Observation. Operators can see how quickly corrosion affects the coupons.

- Material Health. This data reflects the overall condition of the materials used in the infrastructure.

Predicting Infrastructure Lifespan

- Predictive Analysis. By knowing the rate of corrosion, predictions can be made about how long materials will last.

- Proactive Planning. This information helps in planning replacements before failures occur.

Maintaining Safety Standards

- Safety Compliance. Regular monitoring ensures that the infrastructure meets safety standards.

- Risk Reduction. It lowers the risk of catastrophic failures that could endanger lives and the environment.

Aiding in Budgeting

- Cost Forecasting. Understanding corrosion helps forecast the costs of maintenance and replacements.

- Efficient Use of Resources. Budgeting becomes more accurate, ensuring money is well-spent.

Preventing Unexpected Failures

- Reduced Downtime. Preventive maintenance can reduce the frequency and duration of unplanned outages.

- Cost Savings. By avoiding sudden failures, companies save on emergency repairs and lost productivity.

There are no reviews yet.