Overview of Coupons for Corrosion Testing

Corrosion testing coupons are critical tools used across various industries to monitor and evaluate the corrosion rate within infrastructure systems, notably in pipelines, boilers, and processing equipment. These coupons provide valuable data that helps in assessing the corrosiveness of the environment on the materials used in these systems and in determining the effectiveness of corrosion control measures.

Specifications

| Material | Stainless Steel 304、Stainless Steel 316、DSS F51、Carbon Steel A105N、Inconel 625 | |||||||||||||

| Operating Temperature | -20±120 | |||||||||||||

| Features | Firstly, Easy to Operating | |||||||||||||

| Secondly, High Accuracy Long Life | ||||||||||||||

| At last, High Efficiency, Low cost | ||||||||||||||

| Payment | TT/LC | |||||||||||||

| Advantages | Firstly, they are lightweight and flexible. | |||||||||||||

| Secondly, Nice Injection efficiency. | ||||||||||||||

At last, Accurate location tracking.

|

Types of Corrosion Coupons

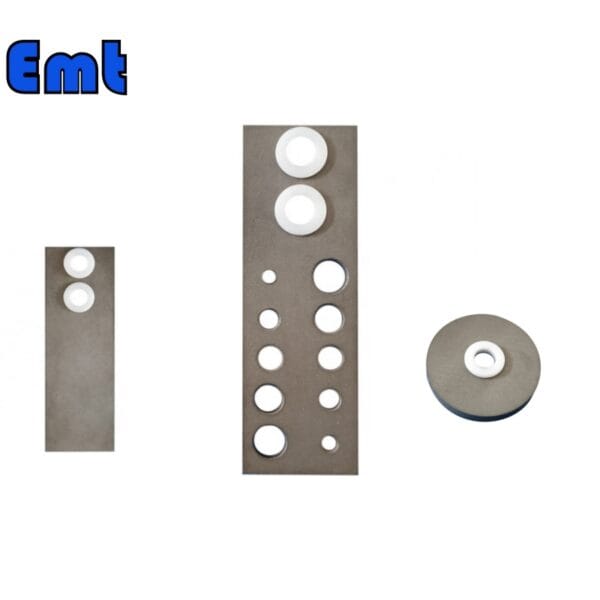

Strip Coupons:

These are the most common type of corrosion coupons and are typically rectangular strips of metal that are exposed to the fluid stream. They offer a straightforward, cost-effective means of measuring the metal loss due to corrosion.

Disc Coupons:

Circular coupons that are used in areas with limited access or where flow conditions are severe. Disc coupons are often used in stacked arrangements for simultaneous exposure to different flow conditions within the same pipeline.

Ladder Strip Coupons:

Designed for use in environments where different corrosion rates might exist in the same system due to changes in flow dynamics or chemistry.

Multi-Hole Coupons:

These are similar to strip coupons but with multiple holes, allowing for differential analysis of fluid flow impact on corrosion rates.

Rod Coupons:

Commonly used in tanks and large diameter pipelines where they can be suspended into the medium being tested.

| Name | Strip Coupon | Multihole Strip Coupon | Disc Coupon |

| Applications | Commonly used for most evaluations. | Use with low-pressure access equipment or through narrow ports that a standard 3/4 inch wide coupon cannot pass. | These circular coupons work in multiple disc monitoring applications. |

| Size | 3”*3/4”*1/16” (76.2mm*19.0mm*3.2mm) | 3”*1/2”*1/16” (76.2mm*12.7mm*3.2) With mounting holes | Φ1.25”(31.8mm)Thickness 1/16”(3.2mm) |

Materials Used in Corrosion Coupons

Carbon Steel: Commonly used for general corrosion monitoring in oil and gas applications.

Stainless Steel 304/316: Offers excellent resistance to general and localized corrosion and is typically used in chemical processing and marine applications.

Copper: Used in systems where microbial corrosion is a concern, such as in cooling water systems.

Aluminum: Applied in environments where aluminum components are prevalent, such as in HVAC systems.

Inconel, Titanium, and Other Alloys: Used for specialized applications where extreme conditions are present.

Key Features of Corrosion Coupons

Material Compatibility: The coupon material is typically the same as or closely mimics the pipeline or system material to provide relevant corrosion data.

Ease of Installation: Coupons are designed for easy installation and retrieval, often requiring minimal system modification.

High Accuracy and Reproducibility: Provides precise measurements of corrosion rates, helping to predict the remaining lifespan of infrastructure.

Applications of Corrosion Coupons

Oil & Gas: Used to monitor corrosion in pipelines and storage tanks.

Chemical Processing: Helps in assessing the corrosion resistance of materials against various chemicals.

Water Treatment: Monitors corrosion rates in pipes and machinery to prevent failures and ensure treatment effectiveness.

Power Generation: Used within boilers and cooling towers to prevent unplanned outages due to corrosion.

Installation and Retrieval

Installation and retrieval procedures for corrosion coupons are critical for obtaining accurate corrosion rate data. Operators typically insert coupons into a pipeline or tank using a coupon rack or holder, exposing them to the system’s environment. After a predetermined exposure period, operators retrieve and analyze the coupons for weight loss, pitting, and other forms of deterioration. They then use these analyses to calculate the corrosion rate.

Conclusion

Corrosion coupons are invaluable for maintaining the integrity and efficiency of industrial systems. By providing direct, empirical data on material degradation, these tools help operators make informed decisions about maintenance schedules, material selection, and corrosion protection strategies, ultimately extending the life of the equipment and minimizing operational costs.

There are no reviews yet.