Corrosion test coupons play a crucial role in pipeline maintenance. These small, metal samples are inserted into the pipeline system to monitor corrosion levels over time. Subsequently, by analyzing these coupons, operators can assess the rate and type of corrosion occurring within the pipeline.

Moreover, corrosion test coupons are small, standardized samples of metal or alloy used in the field of material science and engineering to study the susceptibility of materials to corrosive environments. As a result, these coupons provide essential data that helps in evaluating the longevity and durability of metals used in various industrial applications, from pipelines and marine structures to automotive components and aerospace hardware.

Key Benefits

Accurate Monitoring: Provides real-time data on corrosion rates.

Preventive Maintenance: Helps identify potential issues before they become severe.

Material Compatibility: Ensures pipeline materials remain intact and effective.

Cost Savings: Reduces the need for unexpected repairs by enabling proactive maintenance.

How They Work

Installation: Install the coupon in a representative location within the pipeline.

Exposure: Allow it to be exposed to the same conditions as the pipeline material.

Analysis: Periodically remove and analyze the coupon for signs of corrosion.

Adjustment: Use data to adjust corrosion prevention strategies as needed.

Corrosion test coupons are an essential tool for maintaining pipeline integrity and prolonging the lifespan of pipeline systems.

Purpose of Corrosion Test Coupons

Corrosion test coupons are primarily used to:

Evaluate Material Performance: They allow researchers and engineers to observe and measure the rate of corrosion in a controlled setting, providing insights into how materials will behave under certain environmental conditions.

Material Selection: Subsequently, the results from corrosion testing guide material selection for specific applications, ensuring that the chosen materials will resist environmental degradation and maintain their integrity over time.

Quality Control: Additionally, regular testing with corrosion coupons helps monitor and verify the quality of protective coatings and corrosion inhibitors used on metals.

Predictive Maintenance: Finally, by analyzing the degree of corrosion that has occurred on a test coupon exposed for a predetermined period, maintenance teams can predict the life expectancy of full-scale structural components.

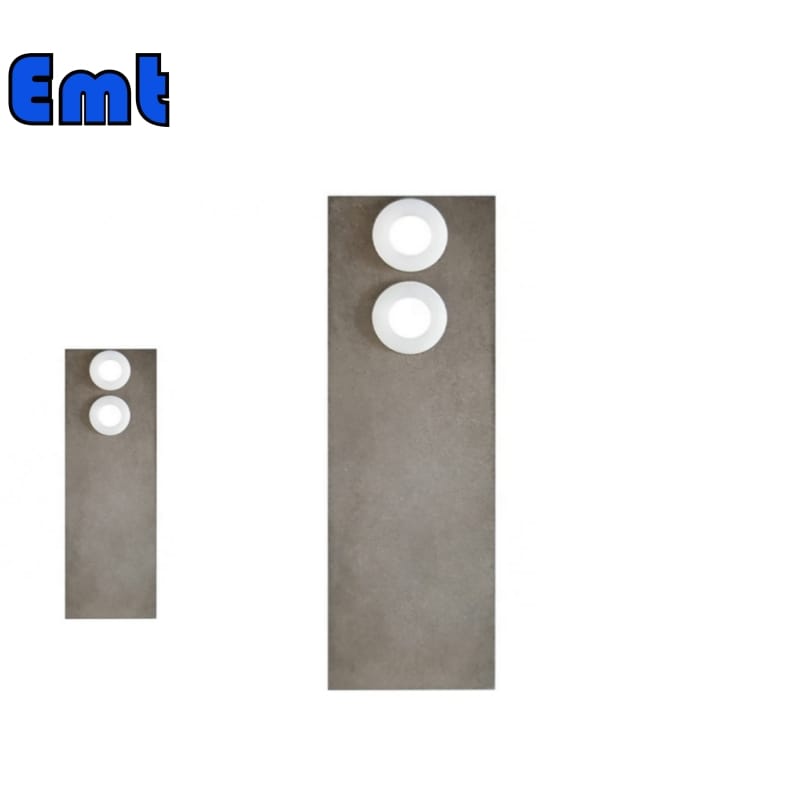

Types of Corrosion Test Coupons

| Name | Strip Coupon | Multihole Strip Coupon | Disc Coupon |

| Applications | Commonly used for most evaluations. | Use with low-pressure access equipment or through narrow ports that a standard 3/4 inch wide coupon cannot pass. | These circular coupons work in multiple disc monitoring applications. |

| Size | 3”*3/4”*1/16” (76.2mm*19.0mm*3.2mm) | 3”*1/2”*1/16” (76.2mm*12.7mm*3.2) With mounting holes | Φ1.25”(31.8mm)Thickness 1/16”(3.2mm) |

1. Flat Coupons: These are the most common form of corrosion coupons, typically rectangular and used in environments where they can be easily mounted to expose a flat surface to the corrosive medium.

2. Cylindrical Coupons: These are used in piping and tubing systems where they mimic the interior conditions of pipes, providing a more accurate representation of internal corrosion rates.

3. Disc Coupons: Often used in fluid systems, these round coupons can be inserted into streams of flowing liquids to simulate real-life conditions inside pumps, valves, and conduits.

4. Custom-shaped Coupons: Some applications require uniquely shaped coupons that match specific component geometries or complex environments.

Applications of Corrosion Test Coupons

Corrosion test coupons are utilized across various industries:

Oil and Gas: Used in pipelines, refineries, and offshore rigs to monitor corrosion that could lead to leaks or catastrophic failures.

Marine: Helps in assessing the corrosion resistance of materials used in ships, submarines, and harbor installations against seawater.

Automotive: Used to test the corrosion resistance of materials used in vehicles, particularly for parts exposed to harsh environments, like underbody components that contact with road salts.

Aerospace: Critical for ensuring the integrity of aircraft components that must withstand high-altitude and variable atmospheric conditions.

Infrastructure: Bridges, water treatment plants, and buildings use corrosion coupons to monitor and extend the lifespan of their structural components.

Installation and Monitoring

To yield meaningful results, you must install and monitor corrosion test coupons correctly:

Installation: You should install coupons to replicate the system’s or structure’s actual conditions. This includes ensuring the proper orientation, flow conditions, and environmental exposure.

Monitoring: Typically, you leave coupons in place for a set duration, which can range from a few weeks to a year, depending on the expected corrosion rates. Then, after removal, you should clean and analyze the coupons to measure the loss of material mass and calculate corrosion rates.

Conclusion

Corrosion test coupons are invaluable in material science, helping to understand and combat the effects of corrosion. Moreover, using these coupons effectively enhances the safety, reliability, and longevity of metal components. Consequently, this leads to significant economic benefits and improved safety standards. Furthermore, corrosion test coupons are crucial for selecting new materials and monitoring existing equipment. Ultimately, they help maintain the integrity of industrial operations.

There are no reviews yet.