There are many types of Chemical Injectors. In this article, we will talk about a Chemical Injector With 316ss Nozzle.

A Chemical Injector with 316 stainless steel (316SS) nozzle delivers precise chemical dosages reliably. The 316SS material excels in corrosion resistance and maintains strength at high temperatures, making it ideal for harsh environments. Industries such as offshore oil drilling and chemical processing benefit greatly from its durability. This resilience ensures long operational life with minimal maintenance.

Furthermore, the injector’s design optimizes chemical delivery for maximum efficiency. It precisely meters the flow of chemicals, maintaining exact concentrations needed for specific processes. High-pressure capabilities and compatibility with various chemicals enhance its utility across many industrial applications. Additionally, its ease of integration and customization options allow for seamless adaptation to specific operational needs. This makes the Chemical Injector with a 316SS nozzle a critical tool for safe and effective chemical handling in demanding settings.

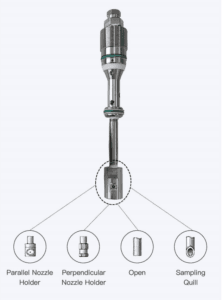

| Types of Nozzles | |

| 1 | Parallel nozzle |

| 2 | Perpendicular nozzle |

| 3 | Open nozzle |

| 4 | Sampling nozzle |

Selection Model of Chemical Injector Quill

| Model | |||||||||||||||||||||||||||

| SI | Chemical Injector Quill | ||||||||||||||||||||||||||

| -Code | Plug | ||||||||||||||||||||||||||

| Pxxx | Type | Material | Sealing Material | ||||||||||||||||||||||||

| 0 | No Request | 0 | CS | 0 | No Request | ||||||||||||||||||||||

| 1 | Hollow Plug Body | 1 | 316SS | 3 | DSS | 1 | Viton O-Ring / PTFE Primary Packing | ||||||||||||||||||||

| 2 | Solid Plug Body | 2 | 316LSS | 4 | INCONEL | 2 | HNBR | ||||||||||||||||||||

| – Code | Injection Nut | ||||||||||||||||||||||||||

| Nxx | Connection Size | Material | |||||||||||||||||||||||||

| 0 | i.e. No Request | 0 | i.e. CS | ||||||||||||||||||||||||

| 1 | i.e. 1/4″ | 1 | i.e. 316SS | 3 | i.e. DSS | ||||||||||||||||||||||

| 2 | i.e. 1/2″ | 2 | i.e. 316LSS | 4 | i.e. INCONEL | ||||||||||||||||||||||

| – Code | Injection Tube | ||||||||||||||||||||||||||

| Sxxx-Lx″ | Connection Size | Material | Nozzle | Line size(x″) | |||||||||||||||||||||||

| 0 | No Request | 0 | CS | 0 | i.e. No Request | The most effective position for injection is generally at the center of the pipe | |||||||||||||||||||||

| 1 | i.e. 1/4″ | 1 | i.e. 316SS | 1 | i.e. Open | ||||||||||||||||||||||

| 2 | i.e. 1/2″ | 2 | i.e. 316LSS | 2 | i.e. Quill | ||||||||||||||||||||||

| 3 | i.e. DSS | 3 | i.e. Cap & Core | ||||||||||||||||||||||||

| 4 | i.e. INCONEL | ||||||||||||||||||||||||||

| – Code | Nipple and Valve(or end Flange)of Tee | ||||||||||||||||||||||||||

| Txx | Connection Size | Material | |||||||||||||||||||||||||

| 0 | i.e. No Request | 0 | i.e. CS | ||||||||||||||||||||||||

| 1 | i.e. 1/4″Nipple | a | i.e. 1/4″Nipple and Valve | 1 | i.e. 316SS | ||||||||||||||||||||||

| 2 | i.e. 1/2″Nipple | b | i.e. 1/2″Nipple and Valve | 2 | i.e. 316LSS | ||||||||||||||||||||||

| 3 | i.e. 3/4″Nipple | c | i.e. 3/4″Nipple and Valve | 3 | i.e. D SS | ||||||||||||||||||||||

| 4 | i.e. 1″Nipple | d | i.e. 1″Nipple and Valve | 4 | i.e. INCONEL | ||||||||||||||||||||||

| 5 | i.e. 1/4″Flange | e | i.e. 1/4″Nipple end Flange | ||||||||||||||||||||||||

| 6 | i.e. 1/2″Flange | f | i.e. 1/2″Nipple end Flange | ||||||||||||||||||||||||

| 7 | i.e. 3/4″Flange | g | i.e. 3/4″Nipple end Flange | ||||||||||||||||||||||||

| 8 | i.e. 1″Flange | h | i.e. 1″Nipple end Flange | ||||||||||||||||||||||||

| For Example, SI-P221-N12-S122-L4″-T22 | |||||||||||||||||||||||||||

| SI:e.g. Sampling & Injection Assembly, | |||||||||||||||||||||||||||

| P221: e.g. Solid Plug Body in 316LSS Viton O-Ring and PTFE Primary Packing, | |||||||||||||||||||||||||||

| N12:e.g. injection Nut Connection Size is 1/4″and Material is 316LSS, | |||||||||||||||||||||||||||

| S122:e.g. injection Tube Connection Size is 1/4″ and Material is 316LSS. The type of nozzle is quills | |||||||||||||||||||||||||||

| L4″:For 4″pipe. | |||||||||||||||||||||||||||

| T22: Nipple of Tee Connection Size is 1/2″, Nipple material is 316LSS | |||||||||||||||||||||||||||

Applications

Chemical Injectors equipped with a 316 stainless steel (316SS) nozzle are indispensable tools in various industrial sectors. They are particularly valuable in the oil and gas industry, where they inject inhibitors and other chemicals to prevent corrosion in pipelines and equipment. The 316SS nozzle’s resistance to saline and chloride environments also makes it ideal for offshore drilling operations. Here, it ensures the safe and accurate delivery of chemicals crucial for maintaining equipment integrity and operational efficiency.

Additionally, these injectors play a critical role in water treatment facilities and chemical processing plants. In water treatment, they precisely dose chemicals like chlorine and flocculants to purify and treat water effectively. In chemical manufacturing, the injector’s ability to withstand aggressive substances allows for the controlled addition of reactants in processes, enhancing product quality and process safety. The robustness of the 316SS nozzle ensures that these injectors can meet the demanding requirements of continuous industrial operations without frequent replacements.

There are no reviews yet.